Ceramics ya silicon karbide (SiC) yagaragaye nkibikoresho byiza byingirakamaro mu bice bya semiconductor, icyogajuru, n’inganda zikora imiti bitewe n’ubushyuhe budasanzwe bw’umuriro, imiterere y’imiti, nimbaraga za mashini. Hamwe nogukenera gukenera ibikoresho byubutaka bukora cyane, byanduye cyane, iterambere ryubuhanga bunoze kandi bunini bwo gutegura ibikoresho byubutaka bwiza bwa SiC byahindutse ubushakashatsi ku isi. Uru rupapuro rusubiramo gahunda yuburyo bukuru bwo gutegura ibikoresho bya Ceramique yubuziranenge, harimo no kongera gukora ibyaha, gucumura ku gahato (PS), gukanda bishyushye (HP), gucumura plasma (SPS), no gukora inyongeramusaruro (AM), hibandwa ku kuganira ku buryo bwo gucumura, ibipimo by'ingenzi, ibintu bifatika, n'ibibazo biriho muri buri gikorwa.

Ikoreshwa ryibumba rya SiC mubisirikare nubuhanga

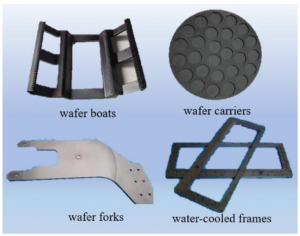

Kugeza ubu, ibikoresho byinshi bya ceramic SiC bikoreshwa cyane mubikoresho byo gukora silicon wafer, bigira uruhare mubikorwa nka okiside, lithographie, etching, hamwe no gutera ion. Hamwe niterambere ryikoranabuhanga rya wafer, kongera ubunini bwa wafer byabaye inzira igaragara. Ingano nyamukuru ya wafer ingano ni 300 mm, igera kuburinganire bwiza hagati yikiguzi nubushobozi bwo gukora. Icyakora, hashingiwe ku mategeko ya Moore, umusaruro wa mm 450 wafers usanzwe uri ku murongo w'ibyigwa. Waferi nini mubisanzwe isaba imbaraga zububiko zo hejuru kugirango zirwanye guhindagurika no guhindura ibintu, bikarushaho gutera imbere kwiyongera kubunini bunini, imbaraga-nyinshi, zifite isuku nyinshi ya SiC ceramic. Mu myaka ya vuba aha, gukora inyongeramusaruro (icapiro rya 3D), nkubuhanga bwihuse bwa prototyping idasaba ko bubaho, bwerekanye imbaraga zidasanzwe muguhimba ibice byubutaka bwa SiC byubatswe bigoye bitewe nubwubatsi bwacyo bwubatswe hamwe nubushobozi bwo gushushanya bworoshye, bikurura abantu benshi.

Uru rupapuro ruzasesengura buri gihe uburyo butanu bwo gutegura uburyo bwo guhanagura ibicuruzwa byiza bya SiC-byongeye gusubirwamo, gucumura bidafite imbaraga, gukanda cyane, gukurura plasma, no gukora inyongeramusaruro - byibanda ku buryo bwo gucumura, ingamba zo kunoza imikorere, ibiranga imikorere, hamwe n’uburyo bukoreshwa mu nganda.

Silicon karbide isukuye cyane

I. Gusubiramo ibyaha

Carbide ya silicon yongeye gushyirwaho (RSiC) ni ibikoresho bya SiC bifite isuku nyinshi byateguwe nta bikoresho bifasha mu bushyuhe bwo hejuru bwa 2100-2500 ° C. Kuva Fredriksson yavumbura bwa mbere ibintu byongeye kugaragara mu mpera z'ikinyejana cya 19, RSiC yitabiriwe n'abantu benshi kubera imbibi zayo zifite isuku no kutagira ibyiciro by'ibirahure n'umwanda. Ku bushyuhe bwinshi, SiC igaragaza umuvuduko mwinshi mwinshi, kandi uburyo bwayo bwo gucumura burimo cyane cyane uburyo bwo guhumeka-guhunika: ibinyampeke byiza bigenda byuka kandi bigasubirana hejuru yintete nini, bigatera imikurire y ijosi no guhuza hagati yintete, bityo bikongerera imbaraga imbaraga.

Mu 1990, Kriegesmann yateguye RSiC ifite ubucucike bugereranije bwa 79.1% akoresheje kunyerera kuri 2200 ° C, hamwe n'umusaraba werekana microstructure igizwe nintete nini na pore. Nyuma, Yi n'abandi. yakoresheje gel casting kugirango ategure imibiri yicyatsi hanyuma ayicumure kuri 2450 ° C, kubona ubukorikori bwa RSiC hamwe nubucucike bwa 2.53 g / cm³ nimbaraga zoroshye za 55.4 MPa.

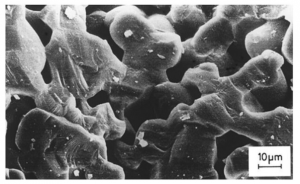

Ubuso bwa SEM bwa RSiC

Ugereranije na SiC yuzuye, RSiC ifite ubucucike buke (hafi 2,5 g / cm³) hamwe na 20% bifungura porotike, bigabanya imikorere yayo mubikorwa bikomeye. Kubwibyo, kunoza ubucucike nubukanishi bwa RSiC byahindutse intego yibanze yubushakashatsi. Indirimbo n'abandi. icyifuzo cyo kwinjira muri silikoni yashongeshejwe muri karubone / β-SiC ivanze no kongera gukora kuri 2200 ° C, kubaka neza urusobe rugizwe nintete nini za α-SiC. RSiC yavuyemo yageze ku bucucike bwa 2,7 g / cm³ n'imbaraga zoroshye za 134 MPa, bikomeza umutekano muke mubushyuhe bwinshi.

Kugirango turusheho kunoza ubucucike, Guo n'abandi. yakoresheje polymer infiltration hamwe na pyrolysis (PIP) tekinoroji yo kuvura RSiC. Ukoresheje PCS / xylene ibisubizo hamwe na SiC / PCS / xylene byihuta nkabacengezi, nyuma yizuba rya 3-6 PIP, ubucucike bwa RSiC bwarushijeho kuba bwiza (kugeza kuri 2,90 g / cm³), hamwe nimbaraga zayo. Byongeye kandi, basabye ingamba zokuzenguruka zihuza PIP no kongera gukora: pyrolysis kuri 1400 ° C hanyuma ikurikirwa na 2400 ° C, ikuraho neza ibibujijwe no kugabanya ububobere. Ibikoresho bya RSiC byanyuma byageze kuri 2,99 g / cm³ nimbaraga za 162.3 MPa, byerekana imikorere idasanzwe.

SEM amashusho yubwihindurize bwa microstructure ya RSiC isukuye nyuma ya polymer yatewe na pyrolysis (PIP) -kuzunguruka: RSiC yambere (A), nyuma yambere ya PIP-recrystallisation (B), na nyuma yicyiciro cya gatatu (C)

II. Kutagira igitutu

Ububumbyi bwa silicon karbide (SiC) ceramics busanzwe butegurwa hifashishijwe isuku ryinshi, ifu ya ultrafine SiC nkibikoresho fatizo, hiyongereyeho udufaranga duke twifashishwa mu gucumura, hanyuma bigacengera mu kirere kitagira ingano cyangwa mu cyuho kuri 1800–2150 ° C. Ubu buryo burakwiriye kubyara ibice binini kandi binini byubatswe na ceramic. Ariko, kubera ko SiC ihujwe cyane cyane, coefficente yayo yo kwikwirakwiza ni mike cyane, bigatuma densisation igorana nta mfashanyo zicumura.

Ukurikije uburyo bwo gucumura, gucumura bidafite umuvuduko birashobora kugabanywamo ibyiciro bibiri: sinteri yumuvuduko wamazi wicyuma (PLS-SiC) hamwe nigitutu kidafite imbaraga (PSS-SiC).

1.1 PLS-SiC (Amazi yo mu cyiciro)

Ubusanzwe PLS-SiC yacumuye munsi ya 2000 ° C hiyongeraho hafi 10 wt. Iyi nzira irakwiriye mubikorwa byubukorikori bwo mu rwego rwa SiC, ariko nta makuru yigeze agaragaza ubuziranenge bwa SiC bwagezweho binyuze mu gucukura ibice.

1.2 PSS-SiC (Icyaha gikomeye-cya Leta)

PSS-SiC ikubiyemo ubukana bwa leta bukomeye ku bushyuhe buri hejuru ya 2000 ° C hamwe na wt 1% yinyongera. Ubu buryo bushingiye cyane cyane ku gukwirakwiza atome no guhinduranya ingano biterwa n'ubushyuhe bwo hejuru kugira ngo bigabanye ingufu z'ubutaka kandi bigere kuri densification. Sisitemu ya BC (boron-karubone) ni inyongeramusaruro isanzwe, ishobora kugabanya ingufu zimbibi zimbuto no gukuraho SiO₂ hejuru ya SiC. Nyamara, inyongera gakondo ya BC akenshi itangiza umwanda usigaye, bigabanya ubuziranenge bwa SiC.

Mu kugenzura ibiyongeweho (B 0.4 wt.%, C 1.8 wt. Microstructure yerekanaga ibinyampeke (bimwe birenga 450 µm z'uburebure), hamwe na pore ntoya kumupaka wimbuto hamwe nuduce twa grafite imbere. Ububumbyi bwerekanaga imbaraga zingana na 443 ± 27 MPa, modulus ya elastike ya 420 ± 1 GPa, hamwe na coefficente yo kwagura ubushyuhe bwa 3.84 × 10⁻⁶ K⁻¹ mubushyuhe bwubushyuhe bwicyumba kugeza kuri 600 ° C, byerekana imikorere myiza muri rusange.

Microstructure ya PSS-SiC: (A) SEM ishusho nyuma yo gusya hamwe na NaOH; (BD) BSD amashusho nyuma yo gusya no gutobora

III. Gucumura Bishyushye

Gukanda cyane (HP) gucumura ni tekinike yo gukwirakwiza icyarimwe ikoresha ubushyuhe hamwe nigitutu cya uniaxial kubikoresho byifu yubushyuhe bwinshi nubushyuhe bukabije. Umuvuduko ukabije urabuza cyane gushinga imyenge no kugabanya imikurire y’ingano, mu gihe ubushyuhe bwo hejuru butera guhuza ingano no gushinga imiterere yuzuye, amaherezo bikabyara ubukana bwinshi, bwera cyane. Bitewe nuburyo bwo gukanda, iyi nzira ikunda gutera ingano anisotropy, bigira ingaruka kumashini no kwambara.

Ubukorikori bwiza bwa SiC buragoye kwiyongera nta nyongeramusaruro, bisaba gucumura ultrahigh-pressure. Nadeau n'abandi. yateguye neza SiC yuzuye yuzuye nta nyongeramusaruro kuri 2500 ° C na 5000 MPa; Izuba n'abandi. yabonye β-SiC ibikoresho byinshi hamwe na Vickers ubukana bugera kuri 41.5 GPa kuri 25 GPa na 1400 ° C. Ukoresheje umuvuduko wa GPa 4, ubukerarugendo bwa SiC bufite ubucucike bugera kuri 98% na 99%, ubukana bwa 35 GPa, hamwe na moderi ya elastike ya 450 GPa byateguwe kuri 1500 ° C na 1900 ° C. Gucumura ifu ya micron ifite ubunini bwa SiC kuri 5 GPa na 1500 ° C byatanze umusaruro wubutaka hamwe nuburemere bwa 31.3 GPa nubucucike bwa 98.4%.

Nubwo ibisubizo byerekana ko umuvuduko wa ultrahigh ushobora kugera ku nyongeramusaruro yubusa, ubunini nigiciro kinini cyibikoresho bisabwa bigabanya imikoreshereze yinganda. Kubwibyo, mugutegura bifatika, inyongeramusaruro cyangwa ifu ya granulation ikoreshwa mugutezimbere imbaraga zo gutwara.

Mugushyiramo 4 wt. Hifashishijwe ingano yinyongera (acide boric na D-fructose) no gucumura kuri 2050 ° C na 40 MPa, SiC ifite isuku nyinshi ifite ubucucike bugereranije> 99.5% nibisigisigi B bisigara 556 ppm gusa. Amashusho ya SEM yerekanaga ko, ugereranije nintangarugero zidafite ingufu, ingero zashyutswe zifite ingano ntoya, imyenge mike, nubucucike buri hejuru. Imbaraga zihindagurika zari 453.7 ± 44.9 MPa, naho moderi ya elastike igera kuri 444.3 ± 1.1 GPa.

Mu kongera igihe cyo gufata kuri 1900 ° C, ingano yiyongereye kuva kuri 1.5 mkm kugeza kuri 1.8 mkm, naho ubushyuhe bwumuriro bwiyongereye kuva kuri 155 bugera kuri 167 W · m⁻¹ · K⁻¹, ari nako byongera imbaraga zo kurwanya ruswa.

Mubihe bya 1850 ° C na 30 MPa, gukanda bishyushye hamwe no gukanda vuba byifu ya SiC ifujwe kandi ifatanye byatanze umusaruro mwinshi β-SiC ceramics nta nyongeramusaruro, ifite ubucucike bwa 3.2 g / cm³ nubushyuhe bukabije bwa 150-200 ° C munsi yuburyo busanzwe. Ubukorikori bwerekanaga ubukana bwa 2729 GPa, ubukana bwavunitse bwa 5.25-5.30 MPa · m ^ 1/2, hamwe no guhangana n’ibikurura neza (igipimo cy’ibikurura cya 9.9 × 10⁻¹⁰ s⁻¹ na 3.8 × 10⁻⁹ s⁻¹ kuri 1400 ° C / 1450 ° C na 100 MPa).

(A) SEM ishusho yubuso bunoze; (B) SEM ishusho yubuso bwavunitse; (C, D) BSD ishusho yubuso bunoze

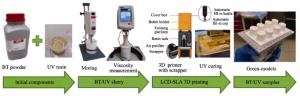

Mu bushakashatsi bwa 3D bwo gucapa kububiko bwa piezoelectric, ceramic slurry, nkibintu byingenzi bigira uruhare mubikorwa no gukora, byahindutse intego yibanze mugihugu ndetse no mumahanga. Ubushakashatsi bugezweho muri rusange bwerekana ko ibipimo nkubunini bwifu yifu, ubunini bwijimye, nibintu bikomeye bigira ingaruka zikomeye kumiterere yibintu na piezoelectric yibicuruzwa byanyuma.

Ubushakashatsi bwerekanye ko ibumba ryibumba ryateguwe hifashishijwe micron-, submicron-, na nano-nini ya barium titanate ifu yerekana itandukaniro rikomeye mubikorwa bya stereolithographe (urugero, LCD-SLA). Mugihe ingano yibice bigabanuka, ibishishwa byijimye byiyongera cyane, hamwe nifu nini ya nano itanga ibishishwa bifite viscositike bigera kuri miliyari mPa · s. Ifu ifite ifu nini ya micron ikunda gusibanganya no gutoborwa mugihe cyo gucapa, mugihe ifu ya subicron na nano nini yerekana imyifatire ihamye. Nyuma yubushyuhe bwo hejuru, ubushakashatsi bwakorewe mubutaka bwageze kuri 5.44 g / cm³, coefficient ya piezoelectric (d₃₃) ya 200 pC / N, hamwe nimpamvu zitakaza igihombo, byerekana uburyo bwiza bwo gusubiza amashanyarazi.

Byongeye kandi, mubikorwa bya micro-stereolithography, uhindura ibintu bikomeye byubwoko bwa PZT (urugero, 75 wt. Ubushakashatsi ku ndishyi ziciriritse zahinduye uburyo bwo gukora neza, kuzamura geometrike kugera kuri 80%.

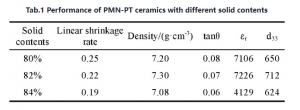

Ubundi bushakashatsi bwakozwe kuri PMN-PT piezoelectric ceramics bwerekanye ko ibintu bikomeye bigira ingaruka zikomeye kumiterere yubutaka nububiko bwamashanyarazi. Kuri 80 wt.% Ibirimo bikomeye, ibicuruzwa byaragaragaye byoroshye mubutaka; nkibirimo bikomeye byiyongereye kugera kuri 82 wt.% no hejuru, ibicuruzwa byacitse buhoro buhoro, kandi imiterere yubutaka bwarushijeho kuba bwiza, hamwe nibikorwa byateye imbere cyane. Kuri 82 wt.

Muncamake, ingano yingirakamaro, ibirimo bikomeye, hamwe nuburyo bwa rheologiya ya ceramic slurries ntabwo bigira ingaruka gusa kumyizerere nukuri kubikorwa byo gucapa ahubwo binagaragaza muburyo butaziguye ubucucike hamwe na piezoelectric ibisubizo byimibiri yacumuye, bikabagira ibipimo byingenzi kugirango ugere kubikorwa bya 3D byacapishijwe piezoelectric ceramics.

Inzira nyamukuru ya LCD-SLA icapiro rya 3D ya BT / UV

Ibiranga PMN-PT ceramics hamwe nibintu bikomeye bitandukanye

IV. Ikirere cya Plasma

Spark plasma sintering (SPS) nubuhanga buhanitse bwo gucumura bukoresha imbaraga zumuvuduko wumuvuduko hamwe nubukanishi icyarimwe bikoreshwa kuri poro kugirango bigerweho vuba. Muri ubu buryo, amashanyarazi ashyushya ifu nifu, bitanga ubushyuhe bwa Joule na plasma, bigafasha gucumura neza mugihe gito (mubisanzwe muminota 10). Ubushyuhe bwihuse butera gukwirakwiza hejuru, mugihe isohoka rya spark rifasha gukuraho imyuka ya adsorbed hamwe na oxyde ya oxyde hejuru yifu, bikanoza imikorere yicyaha. Ingaruka ya electromigration iterwa na electromagnetic imirima nayo yongerera ikwirakwizwa rya atome.

Ugereranije no gukanda gakondo, SPS ikoresha ubushyuhe butaziguye, ituma ubushyuhe bwiyongera mubushyuhe buke mugihe bibuza gukura kwimbuto kugirango ibone microstructures nziza kandi imwe. Urugero:

- Hatariho inyongeramusaruro, ukoresheje ifu ya SiC yubutaka nkibikoresho fatizo, gucumura kuri 2100 ° C na 70 MPa muminota 30 byatanze ingero hamwe nubucucike bwa 98%.

- Gucumura kuri 1700 ° C na 40 MPa muminota 10 byabyaye kubic SiC ifite ubucucike bwa 98% nubunini bwa 30-50 nm gusa.

- Gukoresha ifu ya 80 µm granular ya SiC no gucumura kuri 1860 ° C na MPa 50 muminota 5 byaviriyemo ubukorikori bukomeye bwa SiC hamwe nubucucike bwa 98.5%, Vickers microhardness ya 28.5 GPa, imbaraga zidasanzwe za MPa 395, hamwe no gukomera kwa 4.5 MPa · m ^ 1/2.

Isesengura rya Microstructural ryerekanye ko uko ubushyuhe bwo gucumura bwiyongereye kuva kuri 1600 ° C kugeza kuri 1860 ° C, ubukana bwibintu bwaragabanutse cyane, bwegera ubwinshi bwubushyuhe bwinshi.

Microstructure yubukorikori bwa SiC yacumuye mubushyuhe butandukanye: (A) 1600 ° C, (B) 1700 ° C, (C) 1790 ° C na (D) 1860 ° C

V. Gukora inyongeramusaruro

Gukora inyongeramusaruro (AM) iherutse kwerekana imbaraga zidasanzwe muguhimba ibice bya ceramique bigoye kubera ibikorwa byayo byubaka. Kuri ceramics ya SiC, tekinoroji nyinshi za AM zatejwe imbere, zirimo guhuza binder (BJ), 3DP, gutoranya lazeri (SLS), kwandika wino itaziguye (DIW), hamwe na stereolithography (SL, DLP). Nyamara, 3DP na DIW bifite ubusobanuro buke, mugihe SLS ikunda gutera ubushyuhe bwumuriro no gucika. Ibinyuranye, BJ na SL bitanga inyungu nini mugukora ubuziranenge-bwuzuye, bwuzuye-bwuzuye bwibumba.

- Binder Jetting (BJ)

Ikoranabuhanga rya BJ ririmo gutera intambwe ku yindi ya pande ya poro, hanyuma hagakurikiraho guhanagura no gucumura kugirango ubone ibicuruzwa byanyuma. Guhuza BJ hamwe no kwinjiza imyuka ya chimique (CVI), ubuziranenge-bwuzuye, ceramique ya SiC yuzuye neza. Inzira ikubiyemo:

Gukora SiC ceramic umubiri wicyatsi ukoresheje BJ.

Kwiyongera ukoresheje CVI kuri 1000 ° C na 200 Torr.

C Ceramic ya nyuma ya SiC yari ifite ubucucike bwa 2,95 g / cm³, ubushyuhe bwa 37 W / m · K, nimbaraga za 297 MPa.

Igishushanyo mbonera cy'indege ifata (BJ) icapiro. .

- Stereolithography (SL)

SL ni UV-ikiza-ishingiye kuri ceramic ikora tekinoroji ifite ubuhanga buhanitse cyane kandi ifite ubushobozi bwo guhimba imiterere. Ubu buryo bukoresha ifumbire mvaruganda ya ceramic irimo ibintu byinshi kandi bifite ubukonje buke kugirango habeho umubiri wa 3D ceramic icyatsi kibisi ukoresheje Photopolymerisation, ugakurikirwa no guhanagura hamwe nubushyuhe bwo hejuru kugirango ubone ibicuruzwa byanyuma.

Hifashishijwe 35 vol. Ibisubizo byerekanye ko ingero zateguwe hamwe na 35 vol.

Mugutangiza lipophilique SiO₂ na fenolike epoxy resin (PEA) kugirango ihindure ibicucu, imikorere ya Photopolymerisation yatejwe imbere neza. Nyuma yo gucumura kuri 1600 ° C kuri 4 h, hagezweho guhinduka hafi ya SiC, hamwe na ogisijeni yanyuma ya 0,12% gusa, bituma habaho intambwe imwe yo guhimba isuku ihanitse, yubatswe nubutaka bukomeye bwa SiC itabanje kubamo okiside cyangwa intambwe yo kwinjira mbere.

Ishusho yuburyo bwo gucapa nuburyo bwo gucumura. Kugaragara kwicyitegererezo nyuma yo gukama kuri (A) 25 ° C, pyrolysis kuri (B) 1000 ° C, no gucumura kuri (C) 1600 ° C.

Mugushushanya amafoto ya Si₃N₄ ceramic ya ceramic ya stereolithography ya 3D yo gucapa no gukoresha uburyo bwo gusaza-kubika no gushushanya ubushyuhe bwo hejuru, ubukorikori bwa Si₃N₄ bufite 93.3% yubucucike bwimbaraga, imbaraga zingana na MPa 279.8, nimbaraga za 308.5–333.2 MPa. Ubushakashatsi bwerekanye ko mugihe cya 45 vol. Uburyo bwo kugabanya ubushyuhe buke hamwe nubushyuhe bwa 0.1 ° C / min byafashije kubyara imibiri yicyatsi itarangwamo.

Gucumura ni intambwe yingenzi igira ingaruka kumikorere yanyuma muri stereolithography. Ubushakashatsi bwerekana ko kongeramo imfashanyigisho zishobora kunoza neza ubwinshi bwa ceramic hamwe nubukanishi. Gukoresha CeO₂ nk'imfashanyo yo gucumura hamwe n’ikoranabuhanga rifasha amashanyarazi mu gutegura ibumba ry’ibumba ryinshi rya Si₃N₄, CeO₂ wasangaga itandukanya imbibi z’ingano, iteza imbere imipaka y’ingano no kwiyongera. Ubukorikori bwavuyemo bwerekanaga ubukana bwa Vickers bwa HV10 / 10 (1347.9 ± 2.4) hamwe no gukomera kuvunika kwa (6.57 ± 0.07) MPa · m¹ / ². Hamwe na MgO - Y₂O₃ nk'inyongera, microstructure ceramic microstructure homogeneity yaratejwe imbere, izamura imikorere cyane. Ku rwego rwa doping zose hamwe zingana na 8 wt.

VI. Umwanzuro

Muri make, ububumbyi bwa silicon karbide (SiC) ceramics, nkibikoresho byubuhanga bwububumbyi bw’ubukorikori, byagaragaje uburyo bwagutse bwo gukoresha mu gice cya kabiri, mu kirere, no mu bikoresho bikabije. Uru rupapuro rwasesenguye gahunda eshanu zisanzwe zitegurwa kubutaka bwiza bwa SiC-ceramika-gusubiramo ibyaha, gucumura bidafite umuvuduko, gukanda bishyushye, gucana plasma, no gukora inyongeramusaruro - hamwe n'ibiganiro birambuye kubijyanye n'ubucucike bwazo, uburyo bwiza bwo gukora neza, imikorere myiza, hamwe nibyiza hamwe nimbibi.

Biragaragara ko inzira zitandukanye buriwese afite ibiranga umwihariko muburyo bwo kugera ku isuku ryinshi, ubwinshi bwinshi, imiterere igoye, hamwe ninganda zishoboka. Tekinoroji yinganda ziyongera, byumwihariko, yerekanye imbaraga zikomeye muguhimba ibice bigoye kandi byabigenewe, hamwe niterambere ryagaragaye mubutaka nka stereolithography na binder jetting, bikaba icyerekezo cyingenzi cyiterambere mugutegura ceramic SiC.

Ubushakashatsi bw'ejo hazaza ku itegurwa ry’ubutaka bwa SiC bugomba gucukumbura cyane, bigateza imbere kuva muri laboratoire kugera ku binini binini, byizewe cyane mu buhanga, bityo bigatanga inkunga ikomeye yo gukora ibikoresho byo mu rwego rwo hejuru ndetse n’ikoranabuhanga rizakurikiraho.

XKH ni ikigo cyubuhanga buhanitse kabuhariwe mubushakashatsi no gukora ibikoresho byubutaka bukora neza. Yeguriwe gutanga ibisubizo byabigenewe kubakiriya muburyo bwa ceramika ya silicon karbide (SiC). Isosiyete ifite tekinoroji yo gutegura ibikoresho hamwe nubushobozi bwo gutunganya neza. Ubucuruzi bwayo bukubiyemo ubushakashatsi, umusaruro, gutunganya neza, hamwe no gutunganya hejuru yubutaka bwiza bwa SiC ceramics, bwujuje ibyangombwa bisabwa bya semiconductor, ingufu nshya, icyogajuru nizindi nzego kugirango bikorwe neza cyane. Twifashishije uburyo bwo gucumura bukuze hamwe nubuhanga bwiyongera bwinganda, turashobora guha abakiriya serivisi imwe ihagarikwa kuva muburyo bwiza bwo gukora ibintu, gushiraho imiterere igoye kugeza gutunganya neza, kwemeza ko ibicuruzwa bifite imiterere yubukanishi, ituze ryumuriro hamwe no kurwanya ruswa.

Igihe cyo kohereza: Jul-30-2025

-300x228.png)

1600°C、(B)1700°C、(C)1790°C-和(D)1860°C-300x223.png)

25°C-下干燥、(B)1000°C-下热解和(C)1600°C-下烧结后的外观-300x225.png)