Kuva mu myaka ya za 1980, ubwinshi bwimikorere yumuzunguruko wa elegitoronike bwagiye bwiyongera ku mwaka wa 1.5 × cyangwa byihuse. Kwishyira hamwe kwinshi biganisha kumurongo mwinshi hamwe nubushyuhe mugihe gikora.Niba bidatatanye neza, ubu bushyuhe burashobora gutera kunanirwa kwumuriro no kugabanya igihe cyibikoresho bya elegitoroniki.

Kugirango huzuzwe ibisabwa byogukoresha imicungire yubushyuhe, ibikoresho bya elegitoroniki bipfunyika hamwe nubushuhe buhebuje burimo gukorwaho ubushakashatsi kandi bunoze.

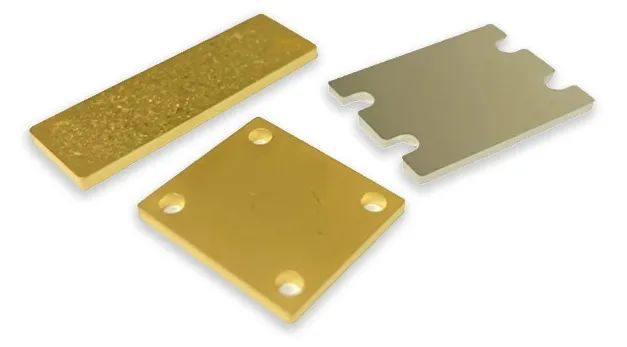

Diamond / umuringa ibikoresho

01 Diyama n'umuringa

Ibikoresho bipfunyika gakondo birimo ububumbyi, plastiki, ibyuma, hamwe nudukoresho twazo. Ububumbyi nka BeO na AlN bwerekana CTEs ihuye na semiconductor, imiti ihamye, hamwe nubushyuhe buringaniye. Nyamara, gutunganya ibintu bigoye, igiciro kinini (cyane cyane uburozi bwa BeO), hamwe nuburiganya bugabanya porogaramu. Ibipfunyika bya plastiki bitanga igiciro gito, uburemere bworoshye, hamwe nubushake ariko bikagira ikibazo cyumuriro muke hamwe nubushyuhe bukabije. Ibyuma bisukuye (Cu, Ag, Al) bifite ubushyuhe bwinshi ariko CTE ikabije, mugihe ibinyomoro (Cu-W, Cu-Mo) bibangamira imikorere yubushyuhe. Rero, ibikoresho byo gupakira bingana kuringaniza ubushyuhe bwinshi hamwe na CTE nziza birakenewe byihutirwa.

| Gushimangira | Amashanyarazi (W / (m · K)) | CTE (× 10⁻⁶ / ℃) | Ubucucike (g / cm³) |

| Diamond | 700-2000 | 0.9–1.7 | 3.52 |

| Ibice bya BeO | 300 | 4.1 | 3.01 |

| Ibice bya AlN | 150-22 | 2.69 | 3.26 |

| Ibice bya SiC | 80–200 | 4.0 | 3.21 |

| B₄C ibice | 29–67 | 4.4 | 2.52 |

| Bor fibre | 40 | ~ 5.0 | 2.6 |

| Ibice bya TiC | 40 | 7.4 | 4.92 |

| Ibice bya Al₂O₃ | 20-40 | 4.4 | 3.98 |

| SiC whiskers | 32 | 3.4 | - |

| Ibice bya Si₃N₄ | 28 | 1.44 | 3.18 |

| TiB₂ | 25 | 4.6 | 4.5 |

| Ibice bya SiO₂ | 1.4 | <1.0 | 2.65 |

Diamond, ibintu bisanzwe bizwi cyane (Mohs 10), nabyo bifite bidasanzweubushyuhe bwumuriro (200-200 W / (m · K)).

Diyama micro-ifu

Umuringa, hamwe na ubushyuhe bwinshi / amashanyarazi (401 W / (m · K)), guhindagurika, no gukoresha neza ibiciro, bikoreshwa cyane muri IC.

Guhuza iyi mitungo,diyama / umuringa (Dia / Cu) igizwe- Hamwe na Cu nka matrix na diyama nkibishimangira-bigenda bigaragara nkibisekuru bizaza ibikoresho byo gucunga amashyuza.

02 Uburyo bwingenzi bwo guhimba

Uburyo busanzwe bwo gutegura diyama / umuringa harimo: ifu ya metallurgie, ubushyuhe bwo hejuru hamwe nuburyo bwumuvuduko mwinshi, uburyo bwo kwibiza gushonga, uburyo bwo gusohora plasma, uburyo bwo gutera imbeho, nibindi.

Kugereranya uburyo butandukanye bwo gutegura, inzira hamwe nimiterere yubunini buke bwa diyama / umuringa

| Parameter | Ifu ya Metallurgie | Vacuum Ashyushye | Ikimenyetso cya Plasma Icumura (SPS) | Umuvuduko mwinshi-Ubushyuhe bwinshi (HPHT) | Ubukonje bukabije | Gushonga |

| Ubwoko bwa Diyama | MBD8 | HFD-D | MBD8 | MBD4 | PDA | MBD8 / HHD |

| Matrix | 99.8% Ifu ya Cu | 99,9% ifu ya electrolytike Cu | Ifu ya Cu 99.9% | Ifu ya Cu ifu | Ifu ya Cu | Cu yuzuye / inkoni |

| Guhindura Imigaragarire | - | - | - | B, Ti, Si, Cr, Zr, W, Mo. | - | - |

| Ingano y'ibice (μm) | 100 | 106–125 | 100–400 | 20–200 | 35–200 | 50–400 |

| Igice cy'ijwi (%) | 20–60 | 40-60 | 35-60 | 60-90 | 20-40 | 60-65 |

| Ubushyuhe (° C) | 900 | 800-1050 | 880–950 | 1100–1300 | 350 | 1100–1300 |

| Umuvuduko (MPa) | 110 | 70 | 40-50 | 8000 | 3 | 1-4 |

| Igihe (min) | 60 | 60–180 | 20 | 6-10 | - | 5-30 |

| Ubucucike bujyanye (%) | 98.5 | 99.2–99.7 | - | - | - | 99.4–99.7 |

| Imikorere | ||||||

| Ibyiza byubushyuhe bwiza (W / (m · K)) | 305 | 536 | 687 | 907 | - | 943 |

Ubuhanga busanzwe bwa Dia / Cu bukubiyemo harimo:

(1)Ifu ya Metallurgie

Ifu ivanze na diyama / Cu ifu irahunikwa kandi iracumura. Mugihe ikiguzi cyoroshye kandi cyoroshye, ubu buryo butanga ubucucike buke, microstructures idafite ingufu, hamwe nubunini bwikitegererezo.

Sigice

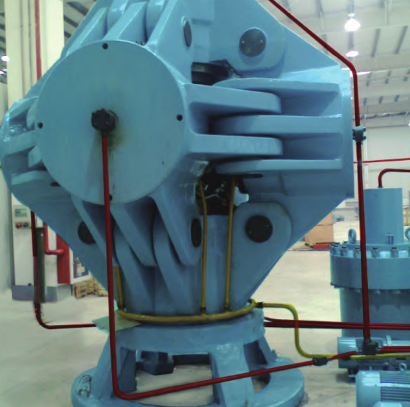

(1)Umuvuduko mwinshi-Ubushyuhe bwinshi (HPHT)

Ukoresheje imashini nyinshi-anvil, Cu yashongeshejwe yinjira muri diyama ya diyama mubihe bikabije, ikabyara ibintu byinshi. Ariko, HPHT isaba ibicuruzwa bihenze kandi ntibikwiye kubyara umusaruro munini.

Cubic

(1)Gushonga

Molten Cu yinjira muri diyama ikoresheje igitutu gifashwa cyangwa capillary-iterwa no kwinjira. Ibisubizo bivamo bigera kuri> 446 W / (m · K) ubushyuhe bwumuriro.

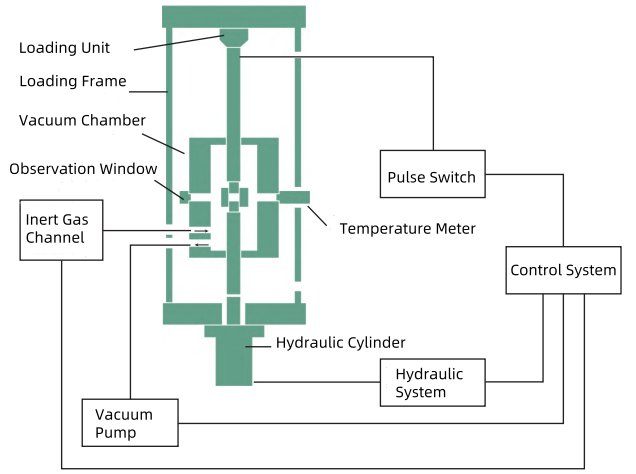

(2)Ikimenyetso cya Plasma Icumura (SPS)

Gusunika amashanyarazi byihuse byivanga ifu munsi yigitutu. Nubwo ikora neza, imikorere ya SPS itesha agaciro uduce twa diyama> 65 vol%.

Igishushanyo mbonera cya sisitemu yo gusohora plasma

(5) Ububiko bukonje

Ifu irihuta kandi igashyirwa kuri substrate. Ubu buryo bwavutse buhura nibibazo muburyo bwo kurangiza kugenzura no kwemeza imikorere yubushyuhe.

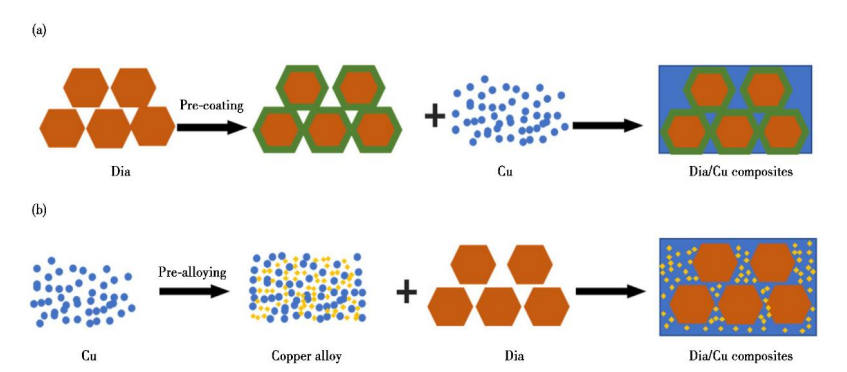

03 Guhindura Imigaragarire

Kugirango hategurwe ibikoresho bikomatanyirijwe hamwe, guhanagura hagati yibigize nikintu cya ngombwa gisabwa kugirango habeho guhuza hamwe nibintu byingenzi bigira ingaruka kumiterere yimiterere no guhuza imiterere. Imiterere idatose kumurongo uri hagati ya diyama na Cu iganisha kumurongo muremure cyane wo kurwanya ubushyuhe. Kubwibyo, ni ngombwa cyane gukora ubushakashatsi bwo guhindura intera hagati yabyo binyuze muburyo bwa tekiniki. Kugeza ubu, hari uburyo bubiri bwo kunoza ikibazo cyimiterere hagati ya diyama na Cu matrix: (1) Kuvura isura ya diyama; (2) Kureka kuvura matrix y'umuringa.

Igishushanyo mbonera cyo guhindura: (a) Isahani itaziguye hejuru ya diyama; (b) Gukuramo Matrix

(1) Guhindura isura ya diyama

Gushyira ibintu bifatika nka Mo, Ti, W na Cr kurwego rwo hejuru rwicyiciro cyo gushimangira birashobora kunoza imiterere yimiterere ya diyama, bityo bikazamura ubushyuhe bwumuriro. Gucumura birashobora gutuma ibintu byavuzwe haruguru byitwara hamwe na karubone hejuru yifu ya diyama kugirango ikore karbide yinzibacyuho. Ibi bitezimbere uburyo bwo guhindagurika hagati ya diyama nigitereko cyicyuma, kandi igifuniko gishobora kubuza imiterere ya diyama guhinduka mubushyuhe bwinshi.

(2) Kuvanga matrix y'umuringa

Mbere yo gutunganya ibikoresho, kubanziriza kuvanga bikorwa kumuringa wibyuma, bishobora kubyara ibikoresho hamwe nubushyuhe bukabije bwumuriro. Gukuraho ibintu bifatika muri matrike y'umuringa ntibishobora kugabanya gusa Inguni itose hagati ya diyama n'umuringa, ariko kandi ikabyara karbide igabanuka cyane muri matrix y'umuringa kuri diyama / Cu nyuma yo kubyitwaramo. Muri ubu buryo, ibyinshi mu byuho biriho kuri interineti bifatika byahinduwe kandi byuzuzwa, bityo bizamura ubushyuhe bwumuriro.

04 Umwanzuro

Ibikoresho bisanzwe bipfunyika bigabanuka mugucunga ubushyuhe buva imbere. Dia / Cu igizwe, hamwe na CTE ihindagurika hamwe na ultrahigh yumuriro wumuriro, byerekana igisubizo gihindura ibisekuruza bizaza.

Nkumushinga wubuhanga buhanitse uhuza inganda nubucuruzi, XKH yibanda kubushakashatsi niterambere no gukora umusaruro wa diyama / umuringa hamwe nibikoresho bya matrix ikora cyane nka SiC / Al na Gr / Cu, bitanga ibisubizo bishya byogukoresha amashanyarazi hamwe nubushyuhe burenga 900W / (m · K) mubice byo gupakira ibikoresho bya elegitoronike, modules yindege hamwe nikirere.

XKH's Diamond umuringa wambaye laminate yibikoresho:

Igihe cyo kohereza: Gicurasi-12-2025