SiC wafer

Silicon karbide (SiC) wafersbabaye insimburangingo yo guhitamo imbaraga-nyinshi, inshuro nyinshi, hamwe nubushyuhe bwo hejuru bwa elegitoroniki hejuru yimodoka, ingufu zishobora kubaho, hamwe nindege. Inshingano zacu zirimo polytypes zingenzi hamwe na gahunda ya doping - azote-yuzuye 4H (4H-N), isuku-y-igice cyinshi (HPSI), azote-yuzuye 3C (3C-N), hamwe na p-4H / 6H (4H / 6H-P) - yatanzwe mu byiciro bitatu byujuje ubuziranenge: PRIME (yuzuye neza, yuzuye ibikoresho) UBUSHAKASHATSI (epi igizwe na profili ya doping ya R&D). Ibipimo bya Wafer bingana na 2 ″, 4 ″, 6 ″, 8 ″, na 12 ″ kugirango bikwiranye nibikoresho byumurage hamwe na fab zateye imbere. Dutanga kandi monocrystalline boules hamwe na kristu yimbuto yerekanwe neza kugirango dushyigikire murugo.

Wafers yacu ya 4H-N iragaragaza ubucucike bwabatwara kuva kuri 1 × 10¹⁶ kugeza kuri 1 × 10¹⁹ cm⁻³ hamwe no guhangana na 0.01-10 Ω · cm, bigatanga moteri nziza ya elegitoronike no kumeneka hejuru ya 2 MV / cm - nibyiza kuri diode ya Schottky, MOSFETs, na JFETs. HPSI insimburangingo irenga 1 × 10¹² Ω · cm irwanya ubukana bwa micropipe munsi ya 0.1 cm⁻², bigatuma imyuka ntoya ya RF na microwave. Cubic 3C-N, iboneka muburyo bwa 2 ″ na 4 ″, ituma heteroepitaxy kuri silicon kandi ishyigikira porogaramu ya Photonic na MEMS. P-ubwoko bwa 4H / 6H-P wafer, yometse kuri aluminium kugeza kuri 1 × 10¹⁶ - 5 × 10¹⁸ cm⁻³, byorohereza ibikoresho byubaka.

Wafer ya SiC, wafers ya PRIME ikorerwa imiti-ya mashini kugeza kuri <0.2 nm RMS hejuru yubuso, ubunini bwuzuye butandukanye munsi ya 3 µm, kandi umuheto <10 µm. DUMMY substrate yihutisha guteranya no gupakira, mugihe wafers YUBUSHAKASHATSI igaragaramo epi-layer yuburebure bwa 2-30 µm na doping bespoke. Ibicuruzwa byose byemejwe na X-ray itandukanya (gutondeka umurongo <30 arcsec) hamwe na Raman spectroscopy, hamwe nibizamini byamashanyarazi - gupima Hall, kwerekana imyirondoro ya C - V, no gusikana micropipe - byemeza JEDEC na SEMI kubahiriza.

Boules igera kuri mm 150 ya diametre ikura hifashishijwe PVT na CVD hamwe nubucucike buri munsi ya cm 1 × 10³ cm na micropipe nkeya. Imbuto za kristu zaciwe muri 0.1 ° ya c-axis kugirango zemeze gukura kwororoka no gutanga umusaruro mwinshi.

Muguhuza polytypes nyinshi, doping variants, amanota meza, ingano ya wafer ya SiC, hamwe nu nzu ya boule hamwe nimbuto-kristu, urubuga rwacu rwa SiC rwerekana iminyururu itanga kandi byihutisha iterambere ryibikoresho kubinyabiziga byamashanyarazi, imiyoboro yubwenge, hamwe n’ibidukikije bikabije.

SiC wafer

Silicon karbide (SiC) wafersbabaye SiC substrate yo guhitamo imbaraga-nyinshi, inshuro nyinshi, hamwe nubushyuhe bwo hejuru bwa elegitoroniki mumashanyarazi, ingufu zishobora kubaho, hamwe nindege. Inshingano zacu zirimo polytypes zingenzi na gahunda ya doping-azote-yuzuye 4H (4H-N), igice kinini-cyera (HPSI), azote-3C (3C-N), na p-4H / 6H (4H / 6H-P) - yatanzwe mu byiciro bitatu byiza: SiC waferPRIME (isukuye neza, ibikoresho-byo mu rwego rwo hejuru), DUMMY (ikubiswe cyangwa idakorewe ibigeragezo), hamwe NUBUSHAKASHATSI (epi igenamigambi hamwe na doping imyirondoro ya R&D). Diameter ya SiC Wafer ifite uburebure bwa 2 ″, 4 ″, 6 ″, 8 ″, na 12 ″ kugirango ihuze ibikoresho byumurage hamwe na fabs zateye imbere. Dutanga kandi monocrystalline boules hamwe na kristu yimbuto yerekanwe neza kugirango dushyigikire murugo.

Wafers yacu ya 4H-N SiC iragaragaza ubucucike bwabatwara kuva kuri 1 × 10¹⁶ kugeza kuri 1 × 10¹⁹ cm⁻³ hamwe no guhangana na 0.01-10 Ω · cm, bigatanga moteri nziza ya elegitoronike no kumeneka hejuru ya 2 MV / cm - nibyiza kuri diode ya Schottky, MOSFETs, na JFETs. HPSI insimburangingo irenga 1 × 10¹² Ω · cm irwanya ubukana bwa micropipe munsi ya 0.1 cm⁻², bigatuma imyuka ntoya ya RF na microwave. Cubic 3C-N, iboneka muburyo bwa 2 ″ na 4 ″, ituma heteroepitaxy kuri silicon kandi ishyigikira porogaramu ya Photonic na MEMS. SiC wafer P-ubwoko bwa 4H / 6H-P wafers, yometse kuri aluminium kugeza kuri 1 × 10¹⁶ - 5 × 10¹⁸ cm⁻³, byorohereza ibikoresho byubaka.

SiC wafer PRIME wafers ikorerwa imiti-yubukanishi kugeza kuri <0.2 nm RMS yubuso bwubuso, ubunini bwuzuye butandukanye munsi ya 3 µm, kandi umuheto <10 µm. DUMMY substrate yihutisha guteranya no gupakira, mugihe wafers YUBUSHAKASHATSI igaragaramo epi-layer yuburebure bwa 2-30 µm na doping bespoke. Ibicuruzwa byose byemejwe na X-ray itandukanya (gutondeka umurongo <30 arcsec) hamwe na Raman spectroscopy, hamwe nibizamini byamashanyarazi - gupima Hall, kwerekana imyirondoro ya C - V, no gusikana micropipe - byemeza JEDEC na SEMI kubahiriza.

Boules igera kuri mm 150 ya diametre ikura hifashishijwe PVT na CVD hamwe nubucucike buri munsi ya cm 1 × 10³ cm na micropipe nkeya. Imbuto za kristu zaciwe muri 0.1 ° ya c-axis kugirango zemeze gukura kwororoka no gutanga umusaruro mwinshi.

Muguhuza polytypes nyinshi, doping variants, amanota meza, ingano ya wafer ya SiC, hamwe nu nzu ya boule hamwe nimbuto-kristu, urubuga rwacu rwa SiC rwerekana iminyururu itanga kandi byihutisha iterambere ryibikoresho kubinyabiziga byamashanyarazi, imiyoboro yubwenge, hamwe n’ibidukikije bikabije.

6inch 4H-N andika urupapuro rwamakuru ya SiC wafer

| 6inch SiC wafers urupapuro rwamakuru | ||||

| Parameter | Sub-Parameter | Z Icyiciro | Icyiciro | D Icyiciro |

| Diameter | 149.5–150.0 mm | 149.5–150.0 mm | 149.5–150.0 mm | |

| Umubyimba | 4H - N. | 350 µm ± 15 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| Umubyimba | 4H - SI | 500 µm ± 15 µm | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Icyerekezo cya Wafer | Off axis: 4.0 ° yerekeza kuri <11-20> ± 0.5 ° (4H-N); Ku murongo: <0001> ± 0.5 ° (4H-SI) | Off axis: 4.0 ° yerekeza kuri <11-20> ± 0.5 ° (4H-N); Ku murongo: <0001> ± 0.5 ° (4H-SI) | Off axis: 4.0 ° yerekeza kuri <11-20> ± 0.5 ° (4H-N); Ku murongo: <0001> ± 0.5 ° (4H-SI) | |

| Ubucucike bwa Micropipe | 4H - N. | ≤ 0.2 cm⁻² | Cm 2 cm⁻² | ≤ 15 cm⁻² |

| Ubucucike bwa Micropipe | 4H - SI | Cm 1 cm⁻² | Cm 5 cm⁻² | ≤ 15 cm⁻² |

| Kurwanya | 4H - N. | 0.015–0.024 Ω · cm | 0.015–0.028 Ω · cm | 0.015–0.028 Ω · cm |

| Kurwanya | 4H - SI | ≥ 1 × 10¹⁰ Ω · cm | ≥ 1 × 10⁵ Ω · cm | |

| Icyerekezo Cyibanze | [10-10] ± 5.0 ° | [10-10] ± 5.0 ° | [10-10] ± 5.0 ° | |

| Uburebure bwibanze | 4H - N. | 47.5 mm ± 2,2 mm | ||

| Uburebure bwibanze | 4H - SI | Ikimenyetso | ||

| Guhezwa | Mm 3 | |||

| Intambara / LTV / TTV / Umuheto | ≤2.5 µm / ≤6 µm / ≤25 µm / ≤35 µm | ≤5 µm / ≤15 µm / ≤40 µm / ≤60 µm | ||

| Ubugome | Igipolonye | Ra ≤ 1 nm | ||

| Ubugome | CMP | Ra ≤ 0.2 nm | Ra ≤ 0.5 nm | |

| Impera | Nta na kimwe | Uburebure bwa mm 20 mm, imwe ≤ 2 mm | ||

| Isahani | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 0.1% | Agace kegeranye ≤ 1% | |

| Uturere twa polytype | Nta na kimwe | Agace kegeranye ≤ 3% | Agace kegeranye ≤ 3% | |

| Carbone | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 3% | ||

| Igishushanyo cyo hejuru | Nta na kimwe | Uburebure bwuzuye ≤ 1 × wafer diameter | ||

| Imipira | Ntanumwe wemerewe ≥ 0.2 mm ubugari & ubujyakuzimu | Kugera kuri 7 chip, mm 1 mm imwe imwe | ||

| TSD (Gutandukanya insanganyamatsiko) | ≤ 500 cm⁻² | N / A. | ||

| BPD (Gusiba Indege Base) | Cm 1000 cm⁻² | N / A. | ||

| Kwanduza Ubuso | Nta na kimwe | |||

| Gupakira | Cassette ya Multi-wafer cyangwa ikintu kimwe cya wafer | Cassette ya Multi-wafer cyangwa ikintu kimwe cya wafer | Cassette ya Multi-wafer cyangwa ikintu kimwe cya wafer | |

4inch 4H-N andika urupapuro rwamakuru ya SiC wafer

| 4inch SiC wafer urupapuro rwamakuru | |||

| Parameter | Umusaruro wa MPD Zeru | Icyiciro cy'umusaruro usanzwe (P Grade) | Icyiciro cya Dummy (D Grade) |

| Diameter | 99,5 mm - 100.0 mm | ||

| Umubyimba (4H-N) | 350 µm ± 15 µm | 350 µm ± 25 µm | |

| Umubyimba (4H-Si) | 500 µm ± 15 µm | 500 µm ± 25 µm | |

| Icyerekezo cya Wafer | Off axis: 4.0 ° yerekeza kuri <1120> ± 0.5 ° kuri 4H-N; Ku murongo: <0001> ± 0.5 ° kuri 4H-Si | ||

| Ubucucike bwa Micropipe (4H-N) | ≤0.2 cm⁻² | ≤2 cm⁻² | ≤15 cm⁻² |

| Ubucucike bwa Micropipe (4H-Si) | ≤1 cm⁻² | ≤5 cm⁻² | ≤15 cm⁻² |

| Kurwanya (4H-N) | 0.015–0.024 Ω · cm | 0.015–0.028 Ω · cm | |

| Kurwanya (4H-Si) | ≥1E10 Ω · cm | ≥1E5 Ω · cm | |

| Icyerekezo Cyibanze | [10-10] ± 5.0 ° | ||

| Uburebure bwibanze | 32,5 mm ± 2,2 mm | ||

| Uburebure bwa kabiri | 18.0 mm ± 2,2 mm | ||

| Icyerekezo cya kabiri cya Flat | Silicon ireba hejuru: 90 ° CW uhereye kumurongo wambere ± 5.0 ° | ||

| Guhezwa | Mm 3 | ||

| LTV / TTV / Umuheto | ≤2.5 µm / ≤5 µm / ≤15 µm / ≤30 µm | ≤10 µm / ≤15 µm / ≤25 µm / ≤40 µm | |

| Ubugome | Igipolonye Ra ≤1 nm; CMP Ra ≤0.2 nm | Ra ≤0.5 nm | |

| Impande Zimenetse Kumucyo mwinshi | Nta na kimwe | Nta na kimwe | Uburebure bwa mm10 mm; uburebure bumwe mm2 mm |

| Isahani ya Hex Kumucyo mwinshi | Agace kegeranye ≤0.05% | Agace kegeranye ≤0.05% | Agace kegeranye ≤0.1% |

| Uturere twa Polytype Kumucyo mwinshi | Nta na kimwe | Agace kegeranye ≤3% | |

| Amashusho ya Carbone | Agace kegeranye ≤0.05% | Agace kegeranye ≤3% | |

| Igishushanyo cya Silicon Igishushanyo Cyinshi Cyumucyo | Nta na kimwe | Uburebure bwuzuye ≤1 wafer diameter | |

| Imipira yimpande yumucyo mwinshi | Nta numwe wemereye ≥0.2 mm z'ubugari n'uburebure | 5 byemewe, mm1 mm imwe imwe | |

| Ubuso bwa Silicon Yanduye Kumucyo mwinshi | Nta na kimwe | ||

| Gutandukanya imigozi | ≤500 cm⁻² | N / A. | |

| Gupakira | Cassette ya Multi-wafer cyangwa ikintu kimwe cya wafer | Cassette ya Multi-wafer cyangwa ikintu kimwe cya wafer | Cassette ya Multi-wafer cyangwa ikintu kimwe cya wafer |

4inch HPSI andika urupapuro rwamakuru ya SiC wafer

| 4inch HPSI andika urupapuro rwamakuru ya SiC wafer | |||

| Parameter | Impamyabumenyi ya Zeru MPD (Z Grade) | Icyiciro cy'umusaruro usanzwe (P Grade) | Icyiciro cya Dummy (D Grade) |

| Diameter | 99.5–100.0 mm | ||

| Umubyimba (4H-Si) | 500 µm ± 20 µm | 500 µm ± 25 µm | |

| Icyerekezo cya Wafer | Off axis: 4.0 ° yerekeza kuri <11-20> ± 0.5 ° kuri 4H-N; Ku murongo: <0001> ± 0.5 ° kuri 4H-Si | ||

| Ubucucike bwa Micropipe (4H-Si) | ≤1 cm⁻² | ≤5 cm⁻² | ≤15 cm⁻² |

| Kurwanya (4H-Si) | ≥1E9 Ω · cm | ≥1E5 Ω · cm | |

| Icyerekezo Cyibanze | (10-10) ± 5.0 ° | ||

| Uburebure bwibanze | 32,5 mm ± 2,2 mm | ||

| Uburebure bwa kabiri | 18.0 mm ± 2,2 mm | ||

| Icyerekezo cya kabiri cya Flat | Silicon ireba hejuru: 90 ° CW uhereye kumurongo wambere ± 5.0 ° | ||

| Guhezwa | Mm 3 | ||

| LTV / TTV / Umuheto | ≤3 µm / ≤5 µm / ≤15 µm / ≤30 µm | ≤10 µm / ≤15 µm / ≤25 µm / ≤40 µm | |

| Ubukonje (C isura) | Igipolonye | Ra ≤1 nm | |

| Ubukonje (Si face) | CMP | Ra ≤0.2 nm | Ra ≤0.5 nm |

| Impande Zimenetse Kumucyo mwinshi | Nta na kimwe | Uburebure bwa mm10 mm; uburebure bumwe mm2 mm | |

| Isahani ya Hex Kumucyo mwinshi | Agace kegeranye ≤0.05% | Agace kegeranye ≤0.05% | Agace kegeranye ≤0.1% |

| Uturere twa Polytype Kumucyo mwinshi | Nta na kimwe | Agace kegeranye ≤3% | |

| Amashusho ya Carbone | Agace kegeranye ≤0.05% | Agace kegeranye ≤3% | |

| Igishushanyo cya Silicon Igishushanyo Cyinshi Cyumucyo | Nta na kimwe | Uburebure bwuzuye ≤1 wafer diameter | |

| Imipira yimpande yumucyo mwinshi | Nta numwe wemereye ≥0.2 mm z'ubugari n'uburebure | 5 byemewe, mm1 mm imwe imwe | |

| Ubuso bwa Silicon Yanduye Kumucyo mwinshi | Nta na kimwe | Nta na kimwe | |

| Gutandukanya imirongo | ≤500 cm⁻² | N / A. | |

| Gupakira | Cassette ya Multi-wafer cyangwa ikintu kimwe cya wafer | ||

Porogaramu ya SiC wafer

-

SiC Wafer Imbaraga Modules ya EV Inverters

SiC wafer ishingiye kuri MOSFETs na diode yubatswe kumurongo wohejuru wa SiC wafer itanga igihombo cya ultra-low switch. Mugukoresha tekinoroji ya wafer ya SiC, izo modules zingufu zikora kuri voltage nubushyuhe bwinshi, bigatuma inverter zikurura neza. Kwinjiza SiC wafer ipfa mubyiciro byamashanyarazi bigabanya gukonjesha no gukandagira ikirenge, byerekana ubushobozi bwuzuye bwo guhanga udushya twa SiC. -

Ibikoresho Byinshi-RF & 5G Ibikoresho kuri SiC Wafer

Amashanyarazi ya RF hamwe na switch byahimbwe kumurongo wa kabiri wa SiC wafer yerekana amashanyarazi meza hamwe na voltage yo kumeneka. SiC wafer substrate igabanya igihombo cya dielectric kuri radiyo ya GHz, mugihe imbaraga za material wa SiC zituma habaho gukora neza mugihe gifite ingufu nyinshi, ubushyuhe bwo hejuru-bigatuma SiC wafer substrate yo guhitamo kuri sitasiyo ya gen 5G hamwe na sisitemu ya radar. -

Optoelectronic & LED Substrates kuva SiC Wafer

LEDs z'ubururu na UV zikura kuri SiC wafer substrate zungukirwa no guhuza lattice nziza hamwe no gukwirakwiza ubushyuhe. Gukoresha C-isura ya C-isura ya SiC itanga ibice bimwe bya epitaxial, mugihe ubukana bwa SiC wafer butuma wafer inanuka kandi igapakira ibikoresho byizewe. Ibi bituma SiC wafer ijya kumurongo wa power-power, igihe kirekire LED ikoreshwa.

Ikibazo cya SiC wafer

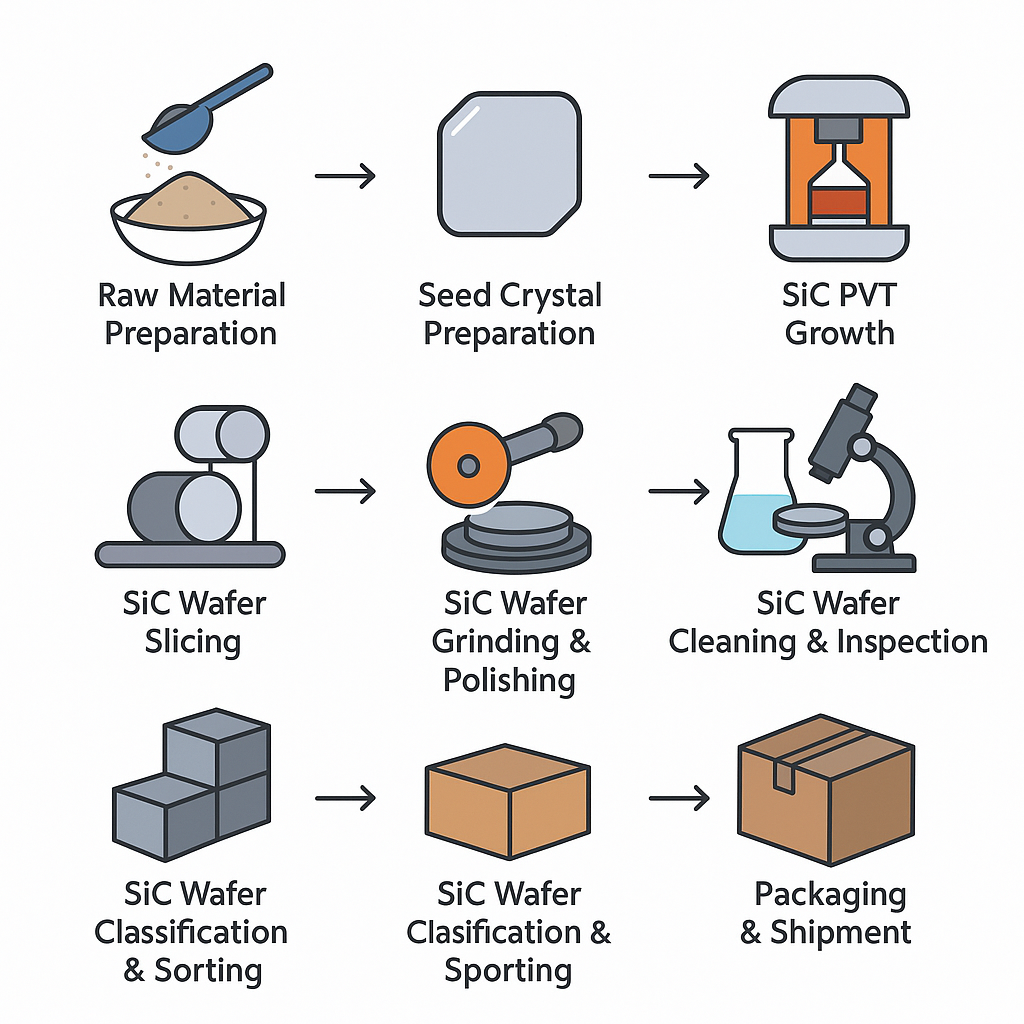

1. Ikibazo: Nigute waferi ya SiC ikorwa?

Igisubizo:

Wafers ya SiC yakozweIntambwe Zirambuye

-

SiC wafersGutegura ibikoresho bibisi

- Koresha ≥5N yo mu rwego rwa SiC ifu (umwanda ≤1 ppm).

- Shungura kandi ubanje guteka kugirango ukureho karubone isigaye cyangwa azote.

-

SiCImbuto Gutegura imbuto

-

Fata igice cya 4H-SiC kristu imwe, gabanya ukurikije 〈0001〉 yerekeza kuri ~ 10 × 10 mm².

-

Polish itomoye kuri Ra ≤0.1 nm hanyuma ushireho icyerekezo cya kristu.

-

-

SiCGukura kwa PVT (Gutwara Imyuka Yumubiri)

-

Ongeramo grafite ingirakamaro: hepfo hamwe nifu ya SiC, hejuru hamwe nimbuto ya kristu.

-

Wimuke kuri 10⁻³ - 10⁻⁵ Torr cyangwa usubize inyuma hamwe na helium yera cyane kuri atm 1.

-

Ubushuhe buturuka kuri 2100-2300 ℃, komeza imbuto 100-150 ℃ gukonjesha.

-

Kugenzura umuvuduko witerambere kuri 1-5 mm / h kugirango uburinganire bwiza nibisohoka.

-

-

SiCIngot Annealing

-

Anneal nkuko byakuze SiC ingot kuri 1600–1800 ℃ kumasaha 4-8.

-

Intego: kugabanya ibibazo byumuriro no kugabanya ubucucike bwa dislocation.

-

-

SiCGukata Wafer

-

Koresha insinga ya diyama kugirango ukate ingot muri mm 0,5-1 mm.

-

Mugabanye kunyeganyega n'imbaraga zo kuruhande kugirango wirinde micro-crack.

-

-

SiCWaferGusya & Polishing

-

Gusya nabigukuraho ibyangiritse (roughness ~ 10–30 µm).

-

Gusya nezakugirango ugere kuburinganire ≤5 µm.

-

Ibikoresho bya Shimi-Imashini (CMP)kugera ku ndorerwamo isa no kurangiza (Ra ≤0.2 nm).

-

-

SiCWaferIsuku & Kugenzura

-

Isuku ya Ultrasonicmuri Piranha igisubizo (H₂SO₄: H₂O₂), amazi ya DI, hanyuma IPA.

-

XRD / Raman yerekanwekwemeza polytype (4H, 6H, 3C).

-

Interferometrygupima uburinganire (<5 µm) na warp (<20 µm).

-

Iperereza ry'ingingo enyekugerageza kwihanganira (urugero: HPSI ≥10⁹ Ω · cm).

-

Kugenzura nezamunsi ya polarike yumucyo microscope hamwe nogupima ibishushanyo.

-

-

SiCWaferGutondekanya & Gutondeka

-

Shungura wafer ukoresheje polytype nubwoko bwamashanyarazi:

-

4H-SiC N-ubwoko (4H-N): kwibanda kwabatwara 10¹⁶ - 10¹⁸ cm⁻³

-

4H-SiC Isuku Yinshi Semi-izingira (4H-HPSI): kurwanya ≥10⁹ Ω · cm

-

6H-SiC N-ubwoko (6H-N)

-

Abandi: 3C-SiC, P-ubwoko, nibindi

-

-

-

SiCWaferGupakira & Kohereza

2. Ikibazo: Ni izihe nyungu zingenzi za waferi ya SiC kuruta wafer ya silicon?

Igisubizo: Ugereranije na silicon wafers, wafers ya SiC itanga:

-

Igikorwa cyo hejuru ya voltage(> 1,200 V) hamwe na on-resistance.

-

Ubushyuhe bwo hejuru(> 300 ° C) no kunoza imicungire yubushyuhe.

-

Umuvuduko wihusehamwe no gutakaza igihombo cyo hasi, kugabanya sisitemu-urwego rwo gukonjesha nubunini mubihindura imbaraga.

4. Ikibazo: Ni izihe nenge zisanzwe zigira ingaruka ku musaruro wa wafer wa SiC?

Igisubizo: Inenge yibanze muri wafers ya SiC harimo micropipes, disikuru yimodoka yibanze (BPDs), hamwe no gushushanya hejuru. Micropipes irashobora gutera ibikoresho byananiranye; BPDs yongera-kurwanya-igihe; no gushushanya hejuru biganisha kumeneka wafer cyangwa gukura nabi epitaxial. Igenzura rikomeye hamwe no kugabanya inenge rero ni ngombwa kugirango umusaruro wa WaC wiyongere.

Igihe cyo kohereza: Jun-30-2025