Mubikorwa byiterambere byiterambere byinganda ziciriritse, zisize kristu imwesilicon waferskugira uruhare rukomeye. Bikora nkibikoresho byibanze byo gukora ibikoresho bitandukanye bya elegitoroniki. Kuva kumurongo utomoye kandi wuzuye uhujwe kugeza kuri microprocessor yihuta cyane hamwe na sensor nyinshi ikora, isukuye kristu imwesilicon wafersni ngombwa. Itandukaniro mubikorwa byabo nibisobanuro bigira ingaruka kuburyo butaziguye ubuziranenge n'imikorere y'ibicuruzwa byanyuma. Hano hepfo nibisanzwe hamwe nibipimo bya polisike imwe ya kirisiti ya silicon:

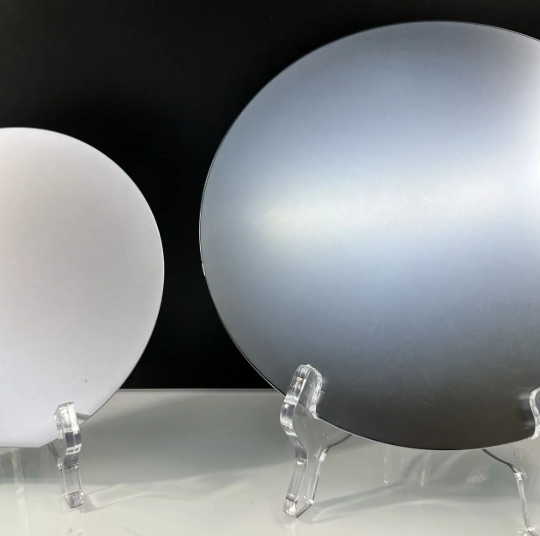

Diameter: Ingano ya semiconductor imwe ya kirisiti ya silicon ya wafer yapimwe na diameter yabo, kandi ikaza muburyo butandukanye. Ibipimo bisanzwe birimo santimetero 2 (50.8mm), santimetero 3 (76.2mm), santimetero 4 (100mm), santimetero 5 (125mm), santimetero 6 (150mm), santimetero 8 (200mm), santimetero 12 (300mm), na santimetero 18 (450mm). Ibipimo bitandukanye bikwiranye nibikorwa bitandukanye bikenerwa nibikorwa bikenewe. Kurugero, waferi ntoya ya diameter isanzwe ikoreshwa kubikoresho bidasanzwe, bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito bito cyane cyane cyane cyane,,,,,,,,,,,,,,, Ubuso busabwa bushyirwa mubikorwa nkuruhande rumwe rusize (SSP) hamwe nimpande ebyiri (DSP). Uruhande rumwe rusizwe neza rukoreshwa mubikoresho bisaba uburinganire burebure kuruhande rumwe, nka sensor zimwe. Wafers ebyiri zogoshywe zikoreshwa mubisanzwe bikoreshwa mukuzunguruka hamwe nibindi bicuruzwa bisaba ibisobanuro bihanitse hejuru yimiterere yombi. Ibisabwa Ubuso (Kurangiza): Uruhande rumwe rusize SSP / Uruhande rumwe rusize DSP.

Ubwoko / Dopant: (1) N-Ubwoko bwa Semiconductor: Iyo atome zimwe zanduye zinjiye muri semiconductor imbere, zihindura imikorere yazo. Kurugero, mugihe ibintu bya pentavalent nka azote (N), fosifore (P), arsenic (As), cyangwa antimoni (Sb) byongeweho, electron zabo za valence zikora imiyoboro ya covalent hamwe na electroni ya valence ya atome ya silicon ikikije, hasigara electron yongeyeho idahambiriwe numubano wa covalent. Ibi bivamo intumbero ya electron irenze umwobo, ikora N-semiconductor ya N, izwi kandi nka semiconductor yo mu bwoko bwa electron. N-ubwoko bwa semiconductor ningirakamaro mubikoresho byo gukora bisaba electron nkabatwara ibintu byingenzi, nkibikoresho bimwe byamashanyarazi. . Ibi biganisha ku mwobo urenze ubunini bwa electron, bigakora P-semiconductor, izwi kandi nka semiconductor yo mu bwoko bwa umwobo. P-ubwoko bwa semiconductor igira uruhare runini mubikoresho byo gukora aho imyobo ikora nkibintu byingenzi bitwara ibintu, nka diode na transistor zimwe.

Kurwanya: Kurwanya ni umubare wingenzi wumubiri upima amashanyarazi yumuriro wa kirisiti imwe ya kirisiti ya silicon. Agaciro kayo kagaragaza imikorere yimyitwarire. Hasi yo kurwanya, niko bigenda neza bya silicon wafer; muburyo bunyuranye, uko birwanya ubukana, niko ubukene bubi. Kurwanya wafer ya silicon bigenwa nibintu byabo bwite, kandi ubushyuhe bugira ingaruka zikomeye nabwo. Mubisanzwe, ubukana bwa silicon wafers bwiyongera hamwe nubushyuhe. Mubikorwa bifatika, ibikoresho bitandukanye bya elegitoroniki bifite ibyangombwa bitandukanye byo kurwanya silicon wafers. Kurugero, wafers ikoreshwa mubikorwa byuzuzanya byumuzunguruko ikenera kugenzura neza kurwanya kugirango ikore neza ibikoresho byizewe kandi byizewe.

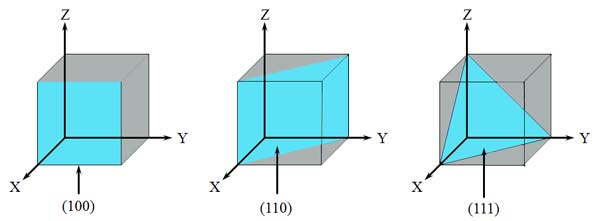

Icyerekezo: Icyerekezo cya kirisiti cyerekana wafer yerekana icyerekezo cya kristu yerekana icyerekezo cya silicon, mubisanzwe byerekanwe na Miller indangagaciro nka (100), (110), (111), nibindi. Iri tandukaniro rishobora kugira ingaruka kumikorere ya wafer mu ntambwe ikurikiraho yo gutunganya hamwe nibikorwa bya nyuma byibikoresho bya mikorobe. Mubikorwa byo gukora, guhitamo wafer ya silicon hamwe nicyerekezo gikwiye kubikoresho bitandukanye bisabwa birashobora guhindura imikorere yibikoresho, kunoza imikorere, no kuzamura ubwiza bwibicuruzwa.

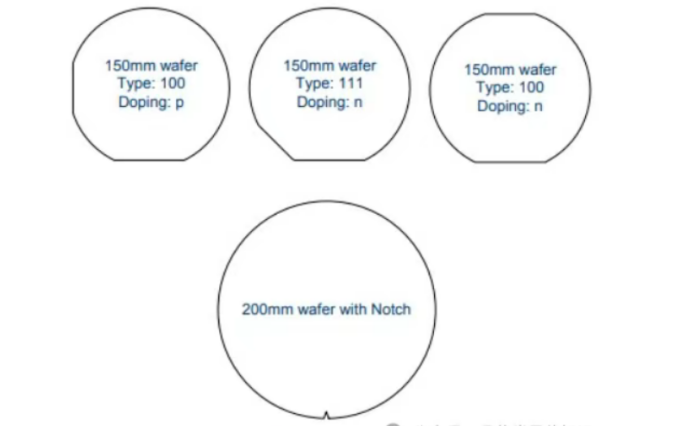

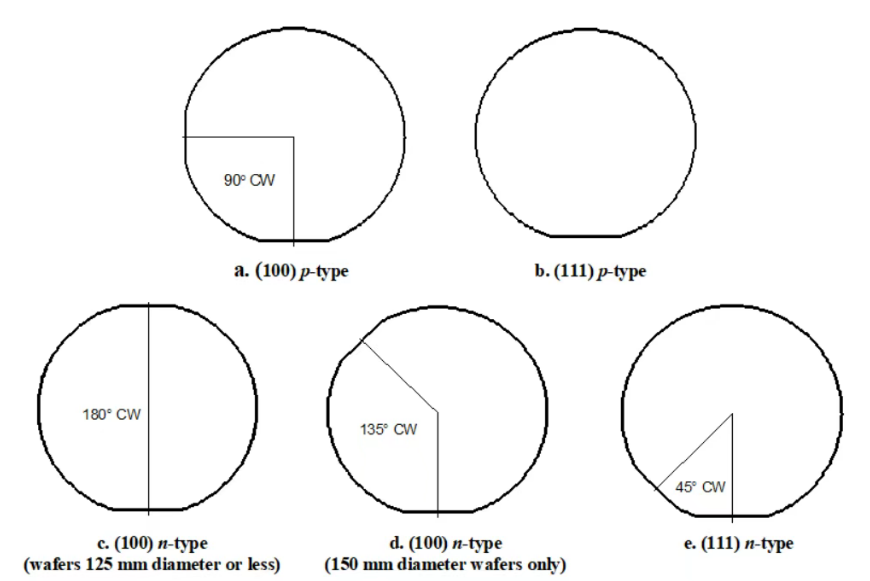

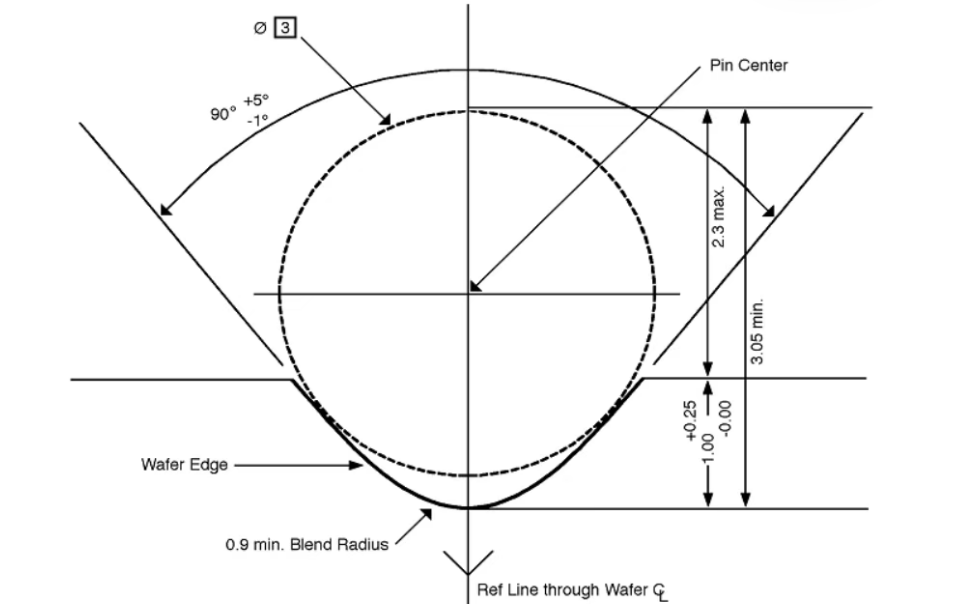

Flat / Notch: Uruhande ruringaniye (Flat) cyangwa V-notch (Notch) kumuzenguruko wa silicon wafer igira uruhare runini muguhuza icyerekezo cya kristu kandi nikimenyetso cyingenzi mugukora no gutunganya wafer. Wafers ya diametre itandukanye ihuye nibipimo bitandukanye kuburebure bwa Flat cyangwa Notch. Guhuza impande zashyizwe mubice byibanze hamwe na kabiri. Igorofa ryibanze rikoreshwa cyane cyane kugirango hamenyekane icyerekezo cyibanze cya kirisiti hamwe nogutunganya ibyerekeranye na wafer, mugihe igorofa ya kabiri irongera ifasha muguhuza no gutunganya neza, gukora neza no guhuza kwa wafer kumurongo wibyakozwe.

Ubunini: Ubunini bwa wafer busanzwe busobanurwa muri micrometero (μm), hamwe n'ubunini busanzwe buri hagati ya 100 mm na 1000μm. Wafers yubunini butandukanye ikwiranye nubwoko butandukanye bwibikoresho bya mikorobe. Wafer yoroheje (urugero, 100μm - 300μm) ikoreshwa kenshi mugukora chip bisaba kugenzura ubukana bukomeye, kugabanya ubunini nuburemere bwa chip no kongera ubucucike. Waferi zibyibushye (urugero, 500μm - 1000μm) zikoreshwa cyane mubikoresho bisaba imbaraga za mashini nyinshi, nkibikoresho bya semiconductor power, kugirango habeho ituze mugihe gikora.

Ubuso bwa Surface: Ubusumbane bwubuso nimwe mubintu byingenzi byerekana gusuzuma ubuziranenge bwa wafer, kuko bigira ingaruka ku buryo butaziguye hagati ya wafer hamwe n’ibikoresho bya firime byashyizwe nyuma, kimwe n’imikorere y’amashanyarazi. Mubisanzwe bigaragazwa nkumuzi usobanura kare (RMS) ubukana (muri nm). Ubuso bwo hasi busobanura ubuso bwa wafer bworoshye, bufasha kugabanya ibintu nko gukwirakwiza electron kandi bigateza imbere imikorere yibikoresho no kwizerwa. Mubikorwa bigezweho byo gukora igice cya kabiri, ibisabwa bikabije biragenda birushaho gukomera, cyane cyane mubikorwa byo murwego rwohejuru rwuzuzanya rwumuzunguruko, aho uburinganire bwubutaka bugomba kugenzurwa kuri nanometero nkeya cyangwa munsi.

Ubunini Bwuzuye Bwuzuye (TTV): Itandukaniro ryubunini bwuzuye bivuga itandukaniro riri hagati yubunini ntarengwa nubunini bupimye ku ngingo nyinshi hejuru ya wafer, ubusanzwe bugaragara muri μm. TTV ndende irashobora kuganisha ku gutandukana mubikorwa nka Photolithography na etching, bigira ingaruka kumikorere yibikoresho no gutanga umusaruro. Kubwibyo, kugenzura TTV mugihe cyo gukora wafer nintambwe yingenzi mu kwemeza ubuziranenge bwibicuruzwa. Kubikoresho bikora neza cyane bya elegitoroniki, TTV irasabwa kuba muri micrometero nkeya.

Umuheto: Umuheto bivuga gutandukana hagati ya wafer hamwe nindege nziza iringaniye, mubisanzwe bipimirwa muri μm. Wafers ifite kunama cyane irashobora gucika cyangwa guhura nimpagarara zingana mugihe cyo gutunganya nyuma, bigira ingaruka kumikorere nubuziranenge bwibicuruzwa. Cyane cyane mubikorwa bisaba uburinganire buringaniye, nka Photolithography, kunama bigomba kugenzurwa murwego runaka kugirango hamenyekane neza niba imiterere ya fotolitografiya.

Intambara: Intambara yerekana gutandukana hagati yubuso bwa wafer nuburyo bwiza bwa serefegitire, nabwo bupimirwa muri μm. Bisa nu muheto, warp nikimenyetso cyingenzi cyerekana uburinganire bwa wafer. Intambara ikabije ntabwo igira ingaruka gusa muburyo bwo gushyira wafer mubikoresho byo gutunganya ahubwo irashobora no guteza ibibazo mugihe cyo gupakira chip, nko guhuza nabi hagati ya chip nibikoresho bipakira, ibyo nabyo bigira ingaruka kumyizerere yibikoresho. Mu nganda zo mu rwego rwo hejuru zikora cyane, ibisabwa byintambara biragenda bikomera kugirango byuzuze ibisabwa byogukora chip hamwe nibikorwa byo gupakira.

Umwirondoro wimpande: Umwirondoro wuruhande rwa wafer ningirakamaro mugutunganya no kugikora. Mubisanzwe byerekanwe na Edge Exclusion Zone (EEZ), isobanura intera kuva kuruhande rwa wafer aho nta gutunganya byemewe. Igishushanyo mbonera cyateguwe neza kandi kugenzura neza EEZ bifasha kwirinda inenge, guhangayikishwa cyane, nibindi bibazo mugihe cyo gutunganya, kuzamura ubwiza bwa wafer hamwe numusaruro. Mubikorwa bimwe byateye imbere mubikorwa byo gukora, ibisobanuro byerekana neza bisabwa kuba kurwego rwa sub-micron.

Kubara Ibice: Umubare nubunini bwo gukwirakwiza ibice hejuru ya wafer bigira ingaruka zikomeye kumikorere yibikoresho bya mikorobe. Ibice byinshi cyangwa binini birashobora gutuma ibikoresho byananirana, nkumuzunguruko mugufi cyangwa kumeneka, kugabanya umusaruro wibicuruzwa. Kubwibyo, kubara ibice mubisanzwe bipimwa mukubara ibice kuri buri gice, nkumubare wibice birenze 0.3 mm. Kugenzura cyane kubara ibice mugihe cyo gukora wafer nigipimo cyingenzi cyo kwemeza ubuziranenge bwibicuruzwa. Ikoranabuhanga rigezweho ryogusukura hamwe nibidukikije bisukuye bikoreshwa mukugabanya kwanduza uduce hejuru ya wafer.

![]()

![]()

![]()

![]()

![]()

Umusaruro ujyanye

Crystal imwe ya Silicon Wafer Si Substrate Ubwoko N / P Ihitamo Silicon Carbide Wafer

FZ CZ Si wafer mububiko 12inch Silicon wafer Prime cyangwa Ikizamini

Igihe cyo kohereza: Apr-18-2025