Ikoranabuhanga rya Wafer, nkintambwe ikomeye mubikorwa byo gukora igice cya kabiri, bifitanye isano itaziguye no gukora chip, umusaruro, nigiciro cyumusaruro.

# 01 Amavu n'amavuko n'akamaro ka Wafer

1.1 Ibisobanuro bya Wafer

Igishushanyo cya Wafer (kizwi kandi nk'abanditsi) ni intambwe y'ingenzi mu gukora igice cya kabiri, kigamije kugabanya wafer yatunganijwe mu rupfu rwabantu benshi. Izi mpfu zisanzwe zirimo imikorere yumuzunguruko kandi nibice byingenzi bikoreshwa mugukora ibikoresho bya elegitoroniki. Mugihe igishushanyo cya chip kigenda kirushaho kuba ingorabahizi kandi ibipimo bikomeza kugabanuka, ibisabwa neza kandi neza kubijyanye na tekinoroji ya wafer igenda irushaho gukomera.

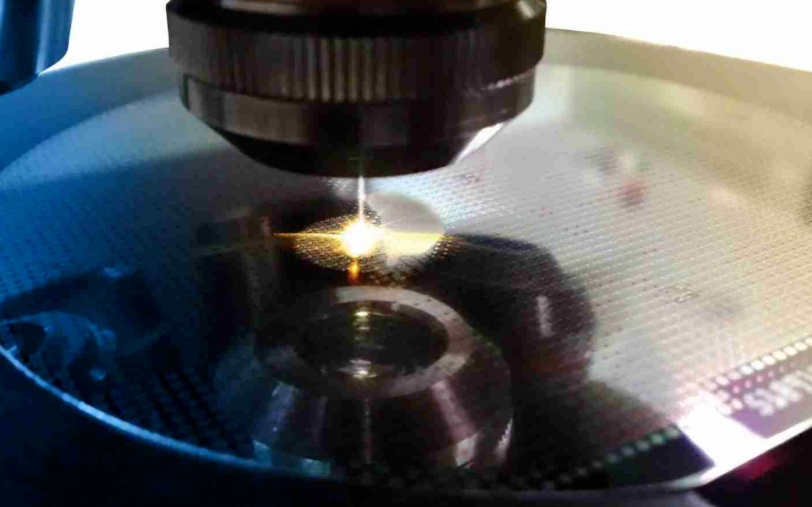

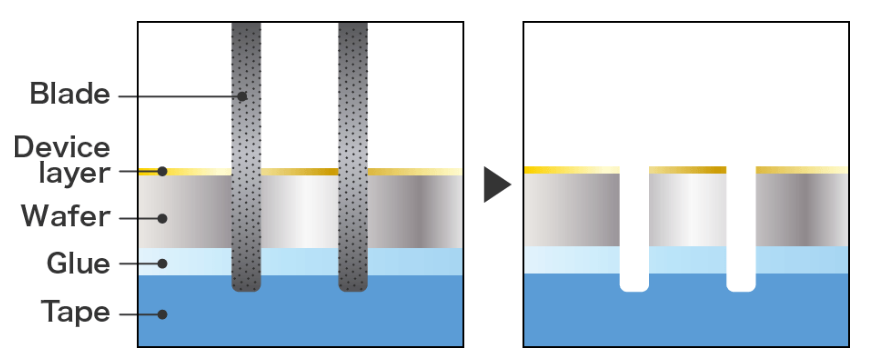

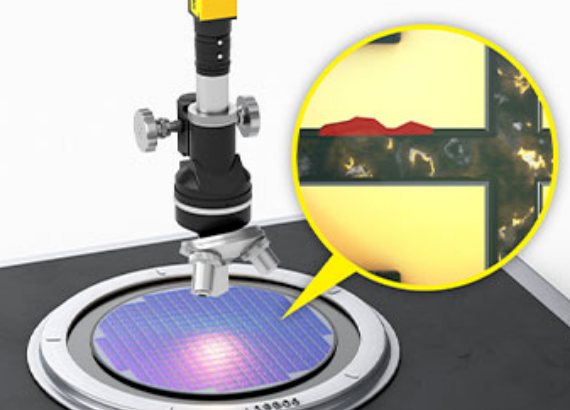

Mubikorwa bifatika, gushushanya wafer mubisanzwe bifashisha ibikoresho bisobanutse neza nka blade ya diyama kugirango buri rupfu rukomeze kuba rwiza kandi rukora neza. Intambwe zingenzi zirimo kwitegura mbere yo gukata, kugenzura neza mugihe cyo gutema, no kugenzura ubuziranenge nyuma yo gukata.

Mbere yo gukata, wafer igomba gushyirwaho ikimenyetso no guhagarikwa kugirango hamenyekane inzira nyayo yo guca. Mugihe cyo gukata, ibipimo nkumuvuduko wibikoresho n'umuvuduko bigomba kugenzurwa cyane kugirango birinde kwangirika kwa wafer. Nyuma yo gukata, ubugenzuzi bwuzuye burakorwa kugirango buri chip yujuje ubuziranenge.

Amahame remezo yikoranabuhanga rya wafer ntabwo akubiyemo gusa guhitamo ibikoresho byo gutema no gushyiraho ibipimo ngenderwaho ahubwo binagira ingaruka kumiterere yubukanishi nibiranga ibikoresho mukugabanya ubuziranenge. Kurugero, waferi ya k-dielectric silicon wafers, kubera imiterere yubukanishi buke, irashobora kwibasirwa cyane no guhangayika mugihe cyo gukata, biganisha kunanirwa nko gukata no guturika. Ubukomezi buke nubunini bwibikoresho-k bito bituma bakunze kwangirika kwububiko hakoreshejwe ingufu za mashini cyangwa guhangayikishwa nubushyuhe, cyane cyane mugihe cyo gutema. Guhuza hagati yigikoresho nubuso bwa wafer, hamwe nubushyuhe bwo hejuru, birashobora kurushaho gukaza umurego.

Hamwe niterambere ryubumenyi bwibikoresho, tekinoroji yo gushushanya ya wafer yagutse irenze semiconductor ishingiye kuri silicon gakondo kugirango ishyiremo ibikoresho bishya nka nitride ya gallium (GaN). Ibi bikoresho bishya, kubera ubukana bwimiterere nuburyo byubatswe, bitera ibibazo bishya kubikorwa byo gushushanya, bisaba ko hajyaho kunonosorwa ibikoresho byo gutema.

Nka nzira ikomeye mu nganda ziciriritse, ibiciro bya wafer bikomeje kunozwa hagamijwe gukemura ibibazo bigenda bitera imbere ndetse n’iterambere ry’ikoranabuhanga, bigashyiraho urufatiro rwa mikorobe y’ikoranabuhanga hamwe n’ikoranabuhanga ry’umuzunguruko.

Gutezimbere muburyo bwa tekinoroji ya wafer birenze iterambere ryibikoresho byingirakamaro. Zikubiyemo kandi uburyo bwiza bwo gutezimbere, kuzamura imikorere yimikorere, no kugenzura neza ibipimo byerekana. Iterambere rigamije kwemeza neza, gukora neza, no gutuza mugikorwa cyo gushushanya wafer, byujuje inganda zikoresha igice cya kabiri gikenera ibipimo bito, kwishyira hamwe, hamwe nuburyo bukomeye bwa chip.

| Agace keza | Ingamba zihariye | Ingaruka |

| Gukwirakwiza inzira | - Kunoza imyiteguro yambere, nkibisobanuro nyabyo bya wafer hamwe no gutegura inzira. | - Kugabanya amakosa yo guca no kunoza ituze. |

| - Kugabanya amakosa yo guca no kuzamura ituze. | - Emera uburyo nyabwo bwo gukurikirana no gutanga ibitekerezo kugirango uhindure igitutu cyibikoresho, umuvuduko, nubushyuhe. | |

| - Hasi ya wafer yo kumeneka no kuzamura ubwiza bwa chip. | ||

| Kongera ibikoresho | - Koresha sisitemu yubukanishi buhanitse hamwe nubuhanga buhanitse bwo kugenzura. | - Kongera gukata neza no kugabanya guta ibikoresho. |

| - Kwinjiza tekinoroji yo gukata laser ikwiranye na wafers yibikoresho bikomeye. | - Kunoza umusaruro no kugabanya amakosa yintoki. | |

| - Ongera ibikoresho byikora kugirango bikurikiranwe kandi bihindurwe. | ||

| Igenzura risobanutse neza | - Hindura neza ibipimo nko guca ubujyakuzimu, umuvuduko, ubwoko bwibikoresho, nuburyo bwo gukonjesha. | - Menya neza ko bapfa ubunyangamugayo no gukora amashanyarazi. |

| - Hindura ibipimo bishingiye kubintu bya wafer, ubunini, n'imiterere. | - Kongera igipimo cy'umusaruro, kugabanya imyanda y'ibikoresho, no kugabanya umusaruro. | |

| Akamaro k'ingamba | - Komeza gushakisha inzira nshya zikoranabuhanga, kunoza inzira, no kongera ubushobozi bwibikoresho kugirango uhuze isoko. | - Kunoza umusaruro wo gukora chip no gukora, ushyigikira iterambere ryibikoresho bishya hamwe nigishushanyo mbonera cya chip. |

1.2 Akamaro ko Kuringaniza Wafer

Igishushanyo cya Wafer gifite uruhare runini mubikorwa byo gukora igice cya kabiri, bigira ingaruka ku ntambwe ikurikiraho kimwe n'ubwiza n'imikorere y'ibicuruzwa byanyuma. Akamaro kayo karashobora gusobanurwa kuburyo bukurikira:

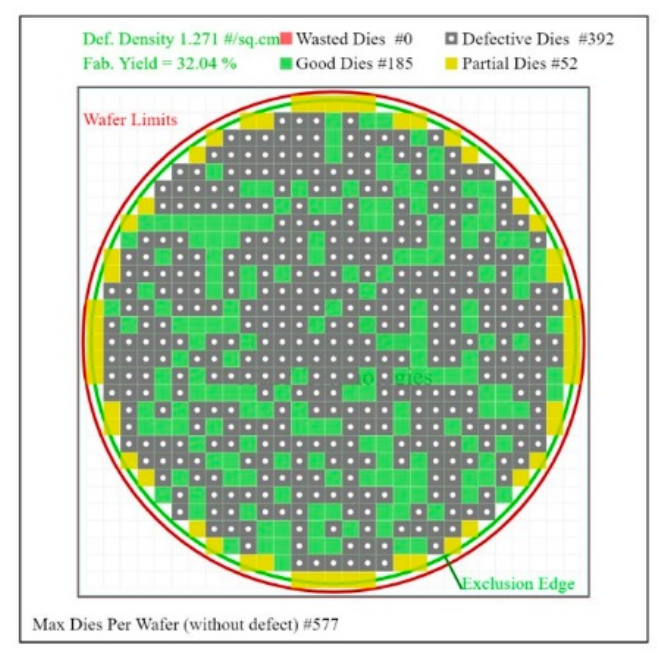

Ubwa mbere, ubunyangamugayo no guhuza ibiciro ni urufunguzo rwo kwemeza umusaruro wa chip no kwizerwa. Mugihe cyo gukora, wafer ikora intambwe nyinshi zo gutunganya kugirango zikore ibintu byinshi bigoye byumuzunguruko, bigomba kugabanywa mubice byihariye (bipfa). Niba hari amakosa akomeye muguhuza cyangwa gukata mugihe cyo gushushanya, imirongo irashobora kwangirika, bikagira ingaruka kumikorere ya chip no kwizerwa. Kubwibyo, tekinoroji yo gushushanya neza ntishobora gusa kuba inyangamugayo ya buri chip ahubwo inarinda kwangirika kwimbere yimbere, kuzamura igipimo rusange cyumusaruro.

Icya kabiri, gushushanya wafer bigira ingaruka zikomeye kumikorere no kugenzura ibiciro. Nintambwe yingenzi mubikorwa byo gukora, imikorere yayo igira ingaruka kuburyo butaziguye intambwe ikurikira. Mugutezimbere uburyo bwo gushushanya, kongera urwego rwimikorere, no kunoza umuvuduko wo kugabanya, umusaruro rusange urashobora kuzamurwa cyane.

Kurundi ruhande, guta ibikoresho mugihe cyo gushushanya nikintu gikomeye mugucunga ibiciro. Gukoresha tekinoroji igezweho yo gushushanya ntibigabanya gusa igihombo cyibintu bitari ngombwa mugihe cyo guca ariko nanone byongera imikoreshereze ya wafer, bityo bikagabanya ibiciro byumusaruro.

Hamwe niterambere mu buhanga bwa semiconductor, diameter ya wafer ikomeza kwiyongera, kandi ubucucike bwumuzunguruko burazamuka bikwiranye, ibyo bikaba bisabwa cyane muburyo bwa tekinoroji. Waferi nini isaba kugenzura neza inzira zo guca inzira, cyane cyane mubice byumuzunguruko mwinshi, aho gutandukana guto bishobora gutanga chip nyinshi zifite inenge. Byongeye kandi, waferi nini zirimo imirongo myinshi yo guca hamwe nintambwe zitoroshye zikorwa, bikenera kurushaho kunozwa muburyo busobanutse, buhoraho, hamwe nuburyo bwiza bwa tekinoroji yo gushushanya kugirango ikemure ibyo bibazo.

1.3

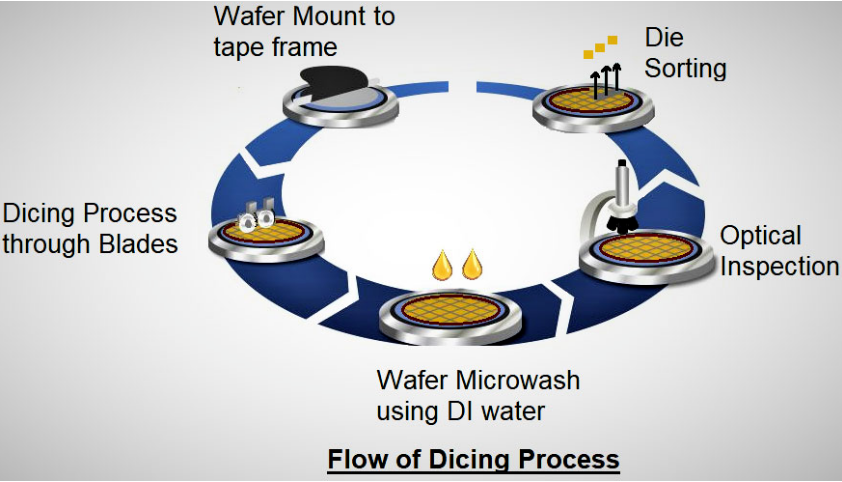

Igikorwa cyo gushushanya wafer gikubiyemo intambwe zose kuva icyiciro cyo kwitegura kugeza kugenzura ubuziranenge bwa nyuma, buri cyiciro kikaba ari ingenzi kugirango harebwe ubuziranenge n'imikorere ya chip. Hano haribisobanuro birambuye kuri buri cyiciro.

| Icyiciro | Ibisobanuro birambuye |

| Icyiciro cyo kwitegura | -Isuku rya Wafer: Koresha amazi meza cyane hamwe nubushakashatsi bwihariye bwogukora isuku, uhujwe na ultrasonic cyangwa mashini yogukora, kugirango ukureho umwanda, ibice, nibihumanya, urebe neza neza. -Umwanya uhamye: Koresha ibikoresho bisobanutse neza kugirango wafer igabanwe neza kumihanda yagenewe gukata. -Gukosora Wafer: Shyira wafer kumurongo wa kaseti kugirango ugumane ituze mugihe cyo gukata, wirinde kwangirika kwinyeganyeza cyangwa kugenda. |

| Gukata Icyiciro | -Kwishushanya: Koresha umuvuduko mwinshi uzunguruka wa diyama isize ibyuma byo gukata kumubiri, bikwiranye nibikoresho bishingiye kuri silikoni kandi bihendutse. -Kumenyekanisha: Koresha urumuri rwinshi rwa lazeri mugukata udahuye, nibyiza kubikoresho byoroshye cyangwa bikomeye cyane nka gallium nitride, bitanga ibisobanuro bihanitse kandi bitakaza ibintu bike. -Ikoranabuhanga Rishya: Kwinjiza tekinoroji yo gukata laser na plasma kugirango urusheho kunoza imikorere no gutondeka mugihe hagabanijwe ubushyuhe bwibasiwe nubushyuhe. |

| Icyiciro cyo Gusukura | - Koresha amazi ya deionioni (amazi ya DI) hamwe nubushakashatsi bwihariye bwogukora isuku, ufatanije nogusukura ultrasonic cyangwa spray, kugirango ukureho imyanda n ivumbi ryakozwe mugihe cyo gutema, wirinde ibisigazwa kutagira ingaruka kumikorere ikurikira cyangwa gukora amashanyarazi. - Amazi meza ya DI yirinda kwinjiza ibintu bishya, kugirango ibidukikije bisukuye. |

| Icyiciro cy'Ubugenzuzi | -Kugenzura neza: Koresha sisitemu yo gutahura optique ihujwe na AI algorithms kugirango umenye vuba inenge, urebe ko nta gucamo cyangwa gukata muri chipi zishushanyije, kunoza imikorere yubugenzuzi, no kugabanya amakosa yabantu. -Igipimo: Kugenzura niba ibipimo bya chip byujuje ibyashizweho. -Ikizamini Cyamashanyarazi: Menya neza ko amashanyarazi akora chip zikomeye zujuje ubuziranenge, byemeza kwizerwa mubisabwa nyuma. |

| Gutondeka Icyiciro | - Koresha amaboko ya robo cyangwa ibikombe bya vacuum kugirango utandukanye chip yujuje ibyangombwa na kaseti ya kaseti hanyuma uhite ubitondekanya ukurikije imikorere, urebe neza umusaruro kandi byoroshye mugihe utezimbere neza. |

Igikorwa cyo guca wafer gikubiyemo gusukura wafer, guhagarara, gukata, gukora isuku, kugenzura, no gutondeka, buri ntambwe iba ikomeye. Hamwe niterambere mu kwikora, gukata lazeri, hamwe na tekinoroji yo kugenzura AI, sisitemu yo gukata wafer igezweho irashobora kugera ku busobanuro buhanitse, umuvuduko, no gutakaza ibikoresho. Mu bihe biri imbere, tekinolojiya mishya yo guca nka laser na plasma izasimbura buhoro buhoro gukata ibyuma kugirango bikemure ibikenerwa bigenda byiyongera, bikarushaho gutera imbere mu bikorwa byo gukora semiconductor.

Gukata Wafer Ikoranabuhanga n'amahame yaryo

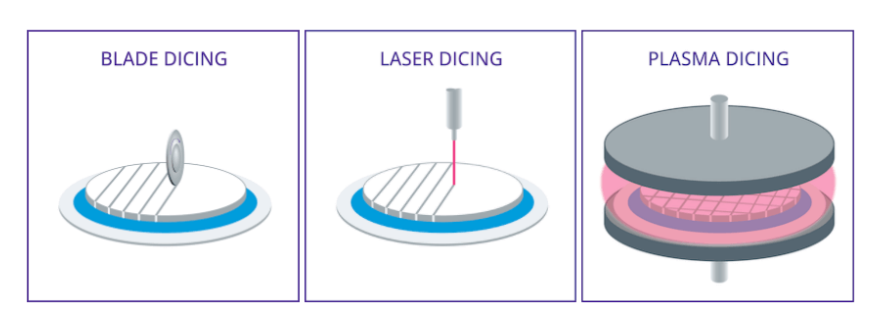

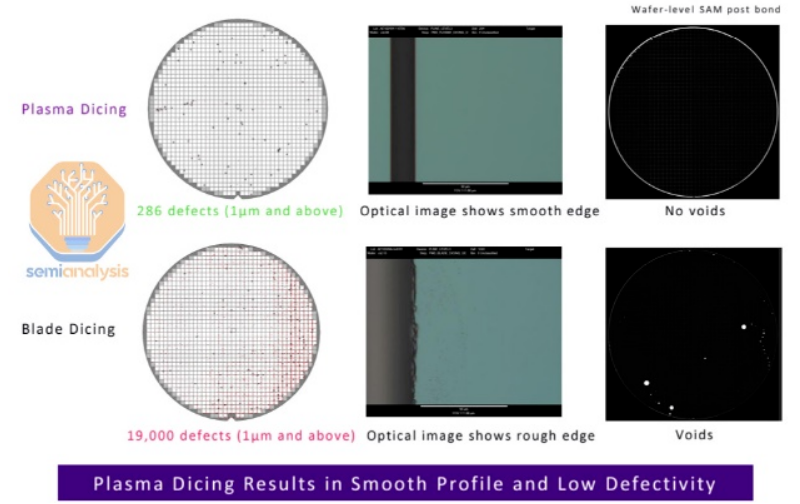

Ishusho yerekana uburyo butatu busanzwe bwo guca wafer:Kwishushanya,Kumenyekanisha, naIndwara ya plasma. Hano hepfo ni isesengura rirambuye hamwe nibisobanuro byiyongera kuri ubu buryo butatu:

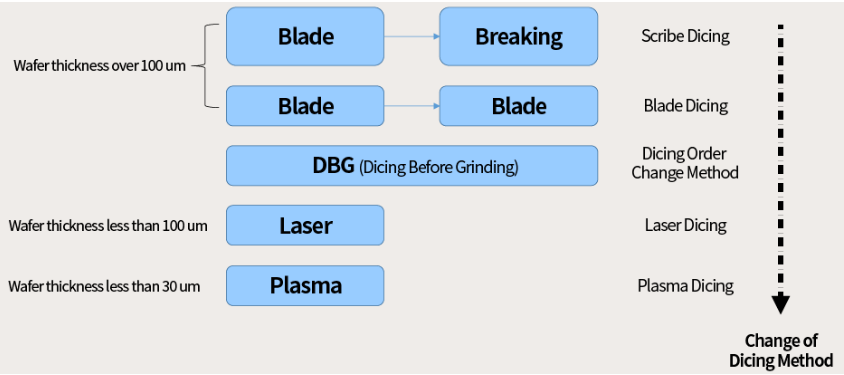

Mu gukora semiconductor, gukata wafer nintambwe yingenzi isaba guhitamo uburyo bukwiye bwo gukata ukurikije ubunini bwa wafer. Intambwe yambere nukumenya ubunini bwa wafer. Niba uburebure bwa wafer burenze microne 100, gushushanya ibyuma birashobora guhitamo nkuburyo bwo guca. Niba gushushanya icyuma bidakwiriye, uburyo bwo kuvunika buvunika burashobora gukoreshwa, burimo gukata abanditsi ndetse nubuhanga bwo gushushanya.

Iyo uburebure bwa wafer buri hagati ya microne 30 na 100, birasabwa uburyo bwa DBG (Dice Mbere yo Gusya). Muri iki kibazo, gukata abanditsi, gushushanya ibyuma, cyangwa guhindura urutonde rwo gukata nkuko bikenewe birashobora guhitamo kugirango ugere kubisubizo byiza.

Kuri ultra-thin wafers ifite umubyimba uri munsi ya microne 30, gukata lazeri bihinduka uburyo bwatoranijwe bitewe nubushobozi bwayo bwo guca waferi yoroheje neza bitarinze kwangiza cyane. Niba gukata laser bidashobora kuzuza ibisabwa byihariye, gukata plasma birashobora gukoreshwa nkubundi buryo. Iyi mbonerahamwe itanga inzira isobanutse yo gufata ibyemezo kugirango tekinoroji ikata ya wafer ikoreshwe mu bihe bitandukanye.

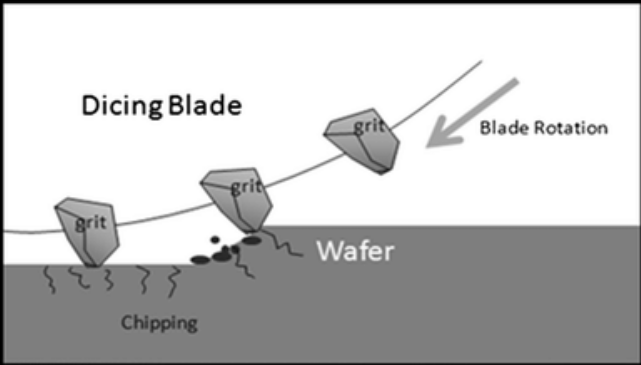

2.1 Ikoranabuhanga ryo gukata imashini

Tekinoroji yo gukata imashini nuburyo gakondo mugushushanya wafer. Ihame shingiro nugukoresha umuvuduko mwinshi uzunguruka uruziga rwa diyama nkigikoresho cyo gukata kugirango ugabanye wafer. Ibikoresho by'ingenzi birimo uruziga rutwara ikirere, rutwara igikoresho cyo gusya cya diyama ku muvuduko mwinshi kugira ngo gikore neza cyangwa gikonjesha mu nzira yagenwe mbere. Iri koranabuhanga rikoreshwa cyane mu nganda bitewe nigiciro cyaryo, imikorere ihanitse, kandi ikoreshwa cyane.

Ibyiza

Gukomera kwinshi no kwambara birwanya ibikoresho byo gusya bya diyama bifasha tekinoroji yo gukata imashini guhuza nogukenera ibikoresho bitandukanye bya wafer, yaba ibikoresho bishingiye kuri silikoni gakondo cyangwa semiconductor nshya. Imikorere yacyo iroroshye, hamwe nibisabwa tekinike nkeya, bikomeza guteza imbere gukundwa kwinshi mubikorwa rusange. Byongeye kandi, ugereranije nubundi buryo bwo gukata nko gukata lazeri, gukata imashini bifite ibiciro byinshi bishobora kugenzurwa, bigatuma bikenerwa kubyara umusaruro mwinshi.

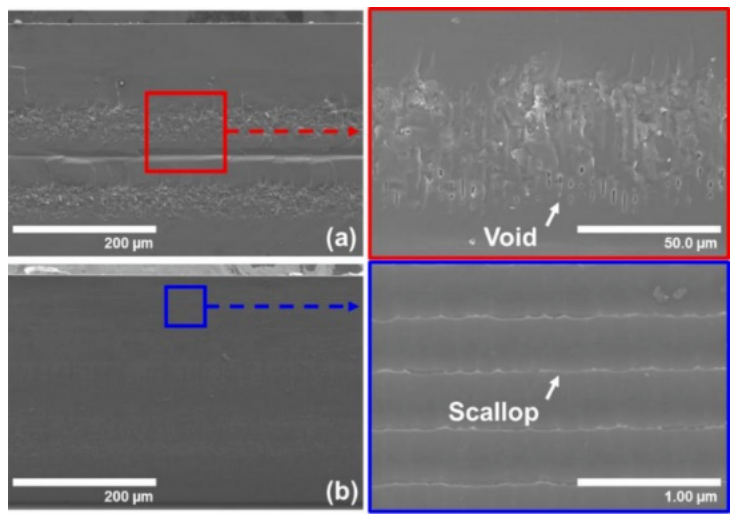

Imipaka

Nubwo ifite ibyiza byinshi, tekinoroji yo gukata imashini nayo ifite aho igarukira. Ubwa mbere, kubera guhuza kumubiri hagati yigikoresho na wafer, gukata neza birasa nkaho bigarukira, akenshi biganisha ku gutandukana kurwego bishobora kugira ingaruka kumpamvu zipakirwa hamwe no kugerageza. Icya kabiri, inenge nko gukata no guturika birashobora kugaragara byoroshye mugihe cyo gukata imashini, ibyo ntibigire ingaruka gusa ku musaruro ahubwo bishobora no kugira ingaruka mbi ku kwizerwa no kubaho kwa chip. Ibyangiritse biterwa na mashini byangiza cyane cyane gukora chip nyinshi cyane, cyane cyane mugukata ibikoresho byoroshye, aho ibyo bibazo bigaragara cyane.

Gutezimbere Ikoranabuhanga

Kugira ngo batsinde izo mbogamizi, abashakashatsi bakomeje kunoza uburyo bwo guca imashini. Iterambere ryibanze ririmo kuzamura igishushanyo noguhitamo ibikoresho byo gusya ibiziga kugirango tunonosore neza kandi biramba. Byongeye kandi, kunonosora imiterere yuburyo bwo kugenzura no kugenzura ibikoresho byo gukata byarushijeho kunoza ituze no gutangiza inzira yo guca. Iterambere rigabanya amakosa yatewe nibikorwa byabantu no kunoza guhuza kugabanuka. Itangizwa ryubugenzuzi buhanitse hamwe nubuhanga bwo kugenzura ubuziranenge bwo kugenzura igihe nyacyo cyo kugenzura ibintu bidasanzwe mugihe cyo gutema nabyo byateje imbere cyane kugabanya kwizerwa no gutanga umusaruro.

Iterambere ry'ejo hazaza hamwe n'ikoranabuhanga rishya

Nubwo tekinoroji yo gukata imashini iracyafite umwanya wingenzi mugukata wafer, tekinoroji nshya yo gukata iratera imbere byihuse uko inzira ya semiconductor igenda ihinduka. Kurugero, ikoreshwa rya tekinoroji yo gukata ya laser itanga ibisubizo bishya kubibazo byuzuye kandi bitagira inenge mugukata imashini. Ubu buryo bwo kudahuza uburyo bwo kugabanya kugabanya imibiri yumubiri kuri wafer, bikagabanya cyane ibyago byo gukata no guturika, cyane cyane iyo ukata ibikoresho byoroshye. Mu bihe biri imbere, guhuza tekinoloji yo gukata imashini hamwe nubuhanga bugenda bugabanuka bizatanga inganda ziciriritse hamwe nuburyo bwinshi kandi bworoshye, bizamura imikorere yinganda nubwiza bwa chip.

Mu gusoza, nubwo tekinoroji yo gukata imashini ifite imbogamizi zimwe na zimwe, kunoza ikoranabuhanga rihoraho no guhuza hamwe nubuhanga bushya bwo gutema bituma bigifite uruhare runini mu gukora imashini itwara imashanyarazi no gukomeza guhangana mu bikorwa biri imbere.

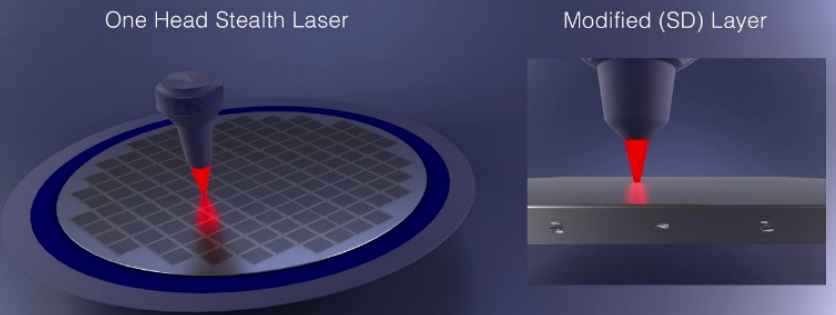

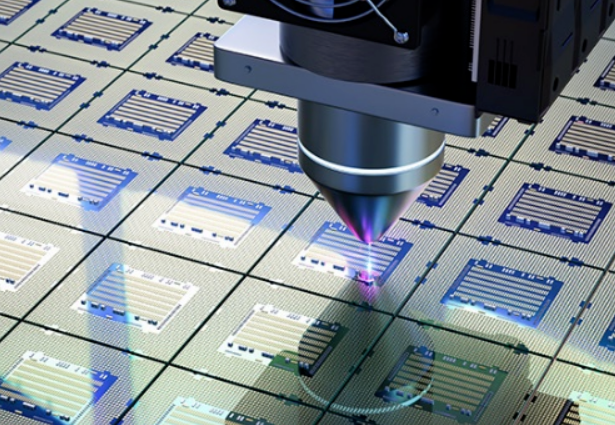

2.2 Ikoreshwa rya tekinoroji

Tekinoroji yo gukata Laser, nkuburyo bushya mugukata wafer, yagiye yitabwaho cyane munganda ziciriritse bitewe nubusobanuro bwayo buhanitse, kutagira imashini yangiza, hamwe nubushobozi bwo guca vuba. Iri koranabuhanga rikoresha ingufu nyinshi hamwe nubushobozi bwo kwibanda kumurongo wa laser kugirango habeho agace gato gaterwa nubushyuhe hejuru yibikoresho bya wafer. Iyo urumuri rwa lazeri rushyizwe kuri wafer, guhangayikishwa nubushyuhe buterwa bituma ibintu bivunika ahabigenewe, bikagera no gukata neza.

Ibyiza bya tekinoroji yo gukata

• Ubusobanuro buhanitse.

• Nta buryo bwo guhuza imashini: Gukata lazeri birinda guhura kumubiri na wafer, birinda ibibazo bisanzwe mugukata imashini, nko gukata no guturika, kuzamura cyane umusaruro wokwizerwa no kwizerwa.

• Kwihuta Kwihuta: Umuvuduko mwinshi wo gukata lazeri ugira uruhare mukwongera umusaruro, bigatuma bikenerwa cyane cyane murwego runini, rwihuta cyane.

Ingorane

• Igiciro Cyibikoresho Byinshi: Ishoramari ryambere ryibikoresho byo gukata lazeri ni byinshi, byerekana igitutu cyubukungu, cyane cyane kubigo bito n'ibiciriritse.

• Igenzura rigoye: Gukata Laser bisaba kugenzura neza ibipimo byinshi, harimo ubwinshi bwingufu, umwanya wibanze, hamwe no kugabanya umuvuduko, bigatuma inzira igorana.

• Ibibazo biterwa nubushyuhe. Ibindi bitezimbere inzira irakenewe kugirango iyi ngaruka igabanuke.

Icyerekezo cyo Gutezimbere Ikoranabuhanga

Kugira ngo ibyo bibazo bikemuke, abashakashatsi bibanda ku kugabanya ibiciro by’ibikoresho, kunoza imikorere yo kugabanya, no kunoza imikorere.

• Lazeri nziza na sisitemu nziza: Mugutezimbere laseri ikora neza hamwe na sisitemu ya optique ya optique, birashoboka kugabanya ibiciro byibikoresho mugihe uzamura guca neza kandi byihuse.

• Kunoza ibipimo ngenderwaho: Ubushakashatsi bwimbitse ku mikoranire hagati ya laseri nibikoresho bya wafer burimo gukorwa kugirango habeho kunoza inzira zigabanya akarere katewe nubushyuhe, bityo kuzamura ubwiza.

Sisitemu yo kugenzura ubwenge: Iterambere rya tekinoroji yo kugenzura ubwenge igamije gukora no guhuza uburyo bwo guca laser, kunoza ituze no guhoraho.

Tekinoroji yo gukata Laser ifite akamaro kanini muri ultra-thin wafers hamwe na sisitemu yo gukata neza. Mugihe ubunini bwa wafer bwiyongera nubucucike bwumuzunguruko bugenda bwiyongera, uburyo bwa gakondo bwo gukata imashini burwanira guhaza ibyifuzo bihanitse kandi bikenerwa cyane ninganda zigezweho. Bitewe nibyiza byihariye, gukata laser birahinduka igisubizo cyatoranijwe muriki gice.

Nubwo tekinoroji yo guca lazeri iracyafite imbogamizi nkigiciro cyibikoresho byinshi hamwe nuburyo bugoye, inyungu zayo zidasanzwe muburyo bwihuse no kwangirika kutabigizemo uruhare bituma iba icyerekezo cyingenzi cyiterambere mubikorwa bya semiconductor. Mugihe tekinoroji ya laser hamwe na sisitemu yo kugenzura ubwenge ikomeje gutera imbere, gukata lazeri biteganijwe ko bizarushaho kunoza uburyo bwo guca wafer no gukora neza, bigatuma iterambere rihoraho ryinganda ziciriritse.

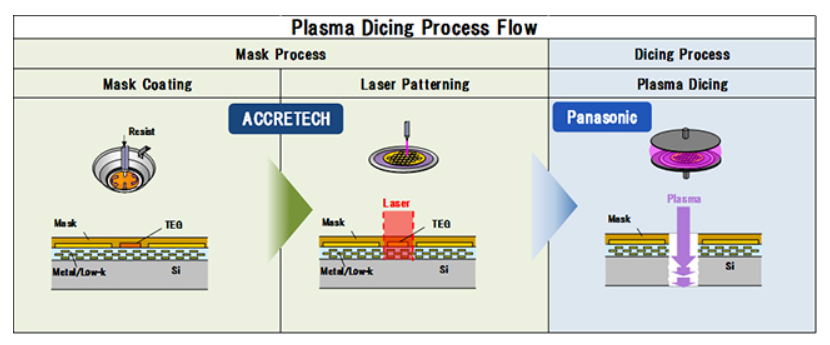

2.3 Ikoreshwa rya Plasma

Tekinoroji yo guca plasma, nkuburyo bugaragara bwa wafer dices, bwitabiriwe cyane mumyaka yashize. Iri koranabuhanga rikoresha ingufu za plasma zifite ingufu nyinshi kugirango ugabanye neza wafer mugucunga ingufu, umuvuduko, ninzira yo guca urumuri rwa plasma, kugera kubisubizo byiza byo guca.

Ihame ry'akazi n'ibyiza

Igikorwa cyo guca plasma gishingiye ku bushyuhe bwo hejuru, ingufu za plasma zifite ingufu nyinshi zakozwe nibikoresho. Uru rumuri rushobora gushyushya ibikoresho bya wafer kugeza aho bishonga cyangwa bigahinduka mugihe gito cyane, bigafasha gukata vuba. Ugereranije no gukata imashini cyangwa lazeri gakondo, gukata plasma birihuta kandi bitanga agace gato gaterwa nubushyuhe, bikagabanya neza ibibaho no kwangirika mugihe cyo gutema.

Mubikorwa bifatika, tekinoroji yo guca plasma ni umuhanga cyane mugukoresha wafer ifite imiterere igoye. Imbaraga zayo nyinshi, zishobora guhindurwa plasma yamashanyarazi irashobora guca byoroshye wafer zifite imiterere idasanzwe kandi neza. Kubwibyo, mubikorwa bya microelectronics, cyane cyane mubikorwa byabigenewe kandi bito-bito byimbuto zo mu rwego rwo hejuru, iri koranabuhanga ryerekana amasezerano akomeye yo gukoreshwa henshi.

Inzitizi n'imbibi

Nubwo ibyiza byinshi byo guca plasma, birahura ningorane zimwe.

• Inzira igoye: Gukata plasma biragoye kandi bisaba ibikoresho bihanitse kandi nabakozi babimenyereye kugirango babyemezeubunyangamugayo no gushikama mugukata.

• Kugenzura ibidukikije n'umutekano.

Icyerekezo cy'iterambere ry'ejo hazaza

Hamwe niterambere ryikoranabuhanga, ibibazo bijyanye no guca plasma biteganijwe ko bizagenda buhoro buhoro. Mugutezimbere ibikoresho byogukata ubwenge kandi bihamye, gushingira kubikorwa byintoki birashobora kugabanuka, bityo bikazamura umusaruro. Muri icyo gihe, guhitamo ibipimo ngenderwaho hamwe no kugabanya ibidukikije bizafasha kugabanya ingaruka z'umutekano hamwe nigiciro cyibikorwa.

Mu nganda ziciriritse, guhanga udushya mu guca wafer no gushushanya ni ngombwa mu guteza imbere inganda. Tekinoroji yo guca plasma, hamwe nibisobanuro byayo bihanitse, ikora neza, hamwe nubushobozi bwo gukora imiterere ya wafer igoye, yagaragaye nkumukinnyi mushya ukomeye muriki gice. Nubwo hari ibibazo bikiriho, ibyo bibazo bizakemurwa buhoro buhoro hamwe no guhanga udushya mu ikoranabuhanga, bizana amahirwe menshi n'amahirwe yo gukora igice cya kabiri.

Ibyifuzo byo gukoresha tekinoroji yo guca plasma ni nini, kandi byitezwe ko bizagira uruhare runini mubikorwa bya semiconductor mugihe kizaza. Binyuze mu guhanga udushya mu ikoranabuhanga no gutezimbere, gukata plasma ntabwo bizakemura ibibazo bihari gusa ahubwo bizanaba imbaraga zikomeye ziterambere ryinganda ziciriritse.

2.4 Gukata ubuziranenge no kugira ingaruka

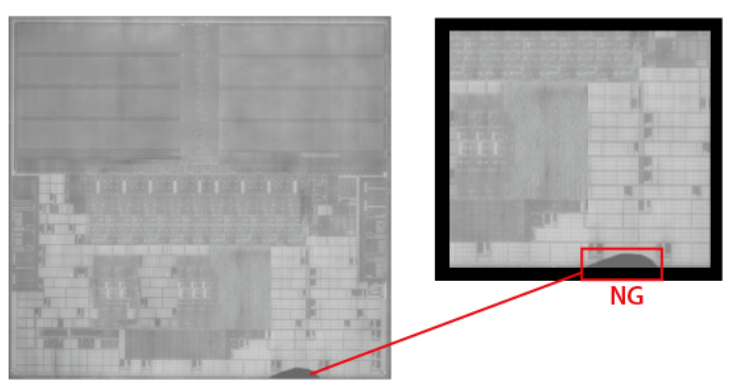

Gukata neza kwa Wafer ningirakamaro kubipapuro bikurikiraho bipakira, kugerageza, hamwe nibikorwa rusange hamwe nubwizerwe bwibicuruzwa byanyuma. Ibibazo bikunze kugaragara mugihe cyo gukata harimo gucamo, gukata, no guca ukubiri. Ibi bibazo biterwa nibintu byinshi bikorana.

| Icyiciro | Ibirimo | Ingaruka |

| Ibipimo | Gukata umuvuduko, kugaburira igipimo, no kugabanya ubujyakuzimu bigira ingaruka ku buryo butajegajega kandi neza. Igenamiterere ridakwiye rirashobora gutuma umuntu ahangayikishwa cyane na zone yibasiwe nubushyuhe bukabije, bikavamo gucikamo ibice. Guhindura ibipimo bikwiye ukurikije ibikoresho bya wafer, ubunini, no gukata ibisabwa ni urufunguzo rwo kugera kubisubizo byifuzwa. | Ibipimo byiza byuburyo byemeza gukata neza no kugabanya ingaruka zinenge nko gucamo no gukata. |

| Ibikoresho nibikoresho | -Ubwiza bw'icyuma: Ibikoresho, ubukana, no kwambara birwanya icyuma bigira ingaruka nziza muburyo bwo gutema no kuringaniza ubuso bwaciwe. Ibyuma bidafite ubuziranenge byongera ubushyamirane hamwe nubushyuhe bwumuriro, birashoboka ko biganisha kumeneka cyangwa gukata. Guhitamo ibikoresho byiza ni ngombwa. -Imikorere ikonje: Coolants ifasha kugabanya ubushyuhe, kugabanya ubukana, hamwe n imyanda isukuye. Gukonjesha kutagira ingaruka birashobora kuganisha ku bushyuhe bwo hejuru no kubaka imyanda, bigira ingaruka ku guca ubuziranenge no gukora neza. Guhitamo ibicurane bikora neza kandi bitangiza ibidukikije ni ngombwa. | Ubwiza bwicyuma bugira ingaruka neza kandi neza. Gukonjesha kutagira ingaruka birashobora kuvamo gukata neza no gukora neza, byerekana ko hakenewe gukoreshwa neza. |

| Kugenzura inzira no kugenzura ubuziranenge | -Igenzura. -Kugenzura Ubuziranenge: Kugenzura nyuma yo gukata kugenzura, gupima ibipimo, no gupima imikorere y'amashanyarazi bifasha kumenya no gukemura ibibazo byubuziranenge vuba, kunoza gukata neza no guhuzagurika. | Kugenzura neza inzira no kugenzura ubuziranenge bifasha kwemeza ibisubizo bihamye, byujuje ubuziranenge bwo kugabanya no kumenya hakiri kare ibibazo bishobora kuvuka. |

Kunoza ubuziranenge bwo gutema

Kunoza ubuziranenge bwo gukata bisaba uburyo bwuzuye buzirikana ibipimo ngenderwaho, ibikoresho no guhitamo ibikoresho, kugenzura inzira, no kugenzura. Mugukomeza kunonosora tekinoroji yo guca no kunoza uburyo bwo gutunganya, uburyo bunoze kandi butajegajega bwo gukata wafer burashobora kurushaho kunozwa, bigatanga ubufasha bwizewe bwa tekiniki yinganda zikora inganda.

# 03 Gukemura nyuma yo gukata no kugerageza

3.1 Isuku no Kuma

Intambwe yo gusukura no kumisha nyuma yo gukata wafer ningirakamaro kugirango harebwe ubwiza bwa chip hamwe niterambere ryimbere ryibikorwa bizakurikiraho. Muri iki cyiciro, ni ngombwa kuvanaho neza imyanda ya silicon, ibisigara bikonje, nibindi byanduza byatewe mugihe cyo gutema. Ni ngombwa kandi kwemeza ko ibyatsi bitangirika mugihe cyogusukura, kandi nyuma yo kumisha, menya neza ko ntamazi aguma hejuru ya chip kugirango wirinde ibibazo nka ruswa cyangwa gusohora amashanyarazi.

Gukemura nyuma yo gukata: Uburyo bwo kweza no gukama

| Intambwe | Ibirimo | Ingaruka |

| Inzira yo Gusukura | -Uburyo: Koresha ibikoresho byabugenewe byogusukura namazi meza, uhujwe nubuhanga bwo koza ultrasonic cyangwa mehaniki yo koza. | Iremeza gukuraho burundu ibyanduye kandi ikarinda kwangirika kwa chipi mugihe cyo gukora isuku. |

| -Guhitamo abakozi: Hitamo ukurikije ibikoresho bya wafer nubwoko bwanduye kugirango urebe neza ko utarangije kwangiza chip. | Guhitamo abakozi neza ni urufunguzo rwo gukora isuku no kurinda chip. | |

| -Kugenzura Parameter: Kugenzura cyane ubushyuhe bwisuku, umwanya, hamwe nisuku yibisubizo kugirango wirinde ibibazo byubuziranenge biterwa no gukora isuku idakwiye. | Igenzura rifasha kwirinda kwangiza wafer cyangwa gusiga ibyanduye inyuma, byemeza ubuziranenge buhoraho. | |

| Uburyo bwo Kuma | -Uburyo gakondo: Kuma ikirere gisanzwe hamwe no guhumeka ikirere gishyushye, gifite ubushobozi buke kandi gishobora gutuma amashanyarazi ahinduka. | Birashobora kuvamo buhoro buhoro ibihe byumye nibibazo bihamye. |

| -Ikoranabuhanga rigezweho: Koresha tekinoroji igezweho nko gukama vacuum no gukama infragre kugirango umenye neza ko chip yumye vuba kandi wirinde ingaruka mbi. | Uburyo bwumye kandi bunoze bwo kumisha, kugabanya ibyago byo gusohora static cyangwa ibibazo bijyanye nubushuhe. | |

| Guhitamo Ibikoresho & Kubungabunga | -Guhitamo ibikoresho: Imashini zisukura cyane kandi zumye zitezimbere gutunganya neza no kugenzura neza ibibazo bishobora kuvuka mugihe cyo gukemura. | Imashini zifite ubuziranenge zituma zitunganywa neza kandi bikagabanya amakosa yamakosa mugihe cyo gukora no gukama. |

| -Kubungabunga ibikoresho: Kugenzura buri gihe no gufata neza ibikoresho byemeza ko bikomeza kumera neza, byemeza ubwiza bwa chip. | Kubungabunga neza birinda ibikoresho kunanirwa, byemeza ko byizewe kandi byujuje ubuziranenge. |

Nyuma yo gukata Isuku no Kuma

Intambwe yo gusukura no kumisha nyuma yo gukata wafer biragoye kandi byoroshye bisaba gutekereza cyane kubintu byinshi kugirango ibisubizo byanyuma bitunganyirizwe. Ukoresheje uburyo bwa siyanse hamwe nuburyo bukomeye, birashoboka kwemeza ko buri chip yinjira mugihe cyo gupakira no kugerageza muburyo bwiza.

Kugenzura Nyuma yo Gukata no Kugerageza

| Intambwe | Ibirimo | Ingaruka |

| Intambwe yo Kugenzura | 1.Kugenzura Amashusho: Koresha ibikoresho byo kugenzura biboneka cyangwa byikora kugirango ugenzure inenge zigaragara nko gucamo, gukata, cyangwa kwanduza hejuru ya chip. Menya vuba vuba ibyangiritse byumubiri kugirango wirinde imyanda. | Ifasha mukumenya no gukuraho chip zifite inenge hakiri kare, kugabanya gutakaza ibintu. |

| 2.Igipimo Ingano: Koresha ibikoresho bipima neza kugirango upime neza ibipimo bya chip, urebe ko ingano yagabanijwe yujuje ibyashushanyije kandi wirinde ibibazo byimikorere cyangwa ingorane zo gupakira. | Menya neza ko chip ziri mubipimo bisabwa, birinda kwangirika kwimikorere cyangwa ibibazo byiteraniro. | |

| 3.Ikizamini Cyamashanyarazi: Suzuma ibyingenzi byamashanyarazi nkurwanya, ubushobozi, hamwe nubushake, kugirango umenye chip zidakurikiza kandi urebe ko chip-yujuje ibyangombwa gusa ikomeza icyiciro gikurikira. | Iremeza gusa imikorere ikora kandi igeragezwa yimikorere itera imbere mubikorwa, bigabanya ibyago byo gutsindwa mubyiciro byanyuma. | |

| Intambwe y'Ikizamini | 1.Ikizamini Cyimikorere: Kugenzura niba imikorere yibanze ya chip ikora nkuko yabigenewe, kumenya no gukuraho chip hamwe nibikorwa bidasanzwe. | Menya neza ko chip zujuje ibyangombwa bisabwa mbere yo gutera imbere. |

| 2.Ikizamini cyo kwizerwa: Suzuma imikorere ya chip itajegajega mugukoresha igihe kirekire cyangwa ibidukikije bikaze, mubisanzwe birimo gusaza k'ubushyuhe bwo hejuru, gupima ubushyuhe buke, hamwe no gupima ubushyuhe kugirango bigereranye ibihe nyabyo bikabije. | Iremeza ko chipi ishobora gukora neza mubihe bitandukanye by ibidukikije, kuzamura ibicuruzwa kuramba no guhagarara neza. | |

| 3.Kwipimisha: Menya neza ko chip ikora neza hamwe nibindi bice cyangwa sisitemu, urebe ko nta makosa cyangwa imikorere idahwitse bitewe no kudahuza. | Iremeza imikorere myiza mubikorwa-byukuri birinda ibibazo guhuza. |

3.3 Gupakira no kubika

Nyuma yo gukata wafer, chip nigisubizo cyingenzi cyibikorwa bya semiconductor, kandi ibyapakiwe hamwe nububiko ni ngombwa kimwe. Ingamba zo gupakira no kubika neza ntabwo ari ngombwa gusa mu kurinda umutekano n’umutekano wa chipi mugihe cyo gutwara no guhunika ariko nanone ni ugutanga inkunga ikomeye kubyakozwe nyuma, kugerageza, no gupakira.

Inshamake yubugenzuzi nicyiciro:

Igenzura nogupima intambwe nyuma yo gukata wafer bikubiyemo ibintu bitandukanye, harimo kugenzura amashusho, gupima ingano, gupima amashanyarazi, kugerageza imikorere, kugerageza kwizerwa, no kugerageza guhuza. Izi ntambwe zirahuzwa kandi ziruzuzanya, zikora inzitizi ikomeye kugirango ibicuruzwa byizewe kandi byizewe. Binyuze mu igenzura rikomeye no kugerageza, ibibazo birashobora kumenyekana no gukemurwa bidatinze, kwemeza ibicuruzwa byanyuma byujuje ibyifuzo byabakiriya nibiteganijwe.

| Icyerekezo | Ibirimo |

| Ingamba zo gupakira | 1.Kurwanya: Ibikoresho byo gupakira bigomba kugira ibintu byiza birwanya anti-static kugirango birinde amashanyarazi ahamye kwangiza ibikoresho cyangwa bigira ingaruka kumikorere yabyo. |

| 2.Ubushuhe: Ibikoresho byo gupakira bigomba kugira ubushyuhe bwiza kugirango birinde kwangirika no kwangirika kwimikorere y amashanyarazi iterwa nubushuhe. | |

| 3.Amashanyarazi: Ibikoresho byo gupakira bigomba gutanga uburyo bwiza bwo guhungabana kugirango urinde imitwe kunyeganyega ningaruka mugihe cyo gutwara. | |

| Ibidukikije | 1.Kugenzura Ubushuhe: Kugenzura cyane ubuhehere mu ntera ikwiye kugirango wirinde kwinjiza amazi no kwangirika biterwa n'ubushuhe bukabije cyangwa ibibazo bihamye biterwa n'ubushuhe buke. |

| 2.Isuku: Komeza ahantu heza ho kubika kugirango wirinde kwanduza umukungugu n'umwanda. | |

| 3.Kugenzura Ubushyuhe: Shiraho ubushyuhe bwuzuye kandi ugumane ubushyuhe kugirango wirinde gusaza vuba kubera ubushyuhe bukabije cyangwa ibibazo bya kondegene biterwa n'ubushyuhe buke. | |

| Kugenzura buri gihe | Buri gihe ugenzure kandi usuzume chip zabitswe, ukoresheje ubugenzuzi bugaragara, ibipimo by'ubunini, hamwe n'ibizamini by'amashanyarazi kugirango umenye kandi ukemure ibibazo bishobora kuvuka mugihe gikwiye. Ukurikije igihe cyo kubika nibisabwa, tegura gukoresha chip kugirango urebe ko ikoreshwa muburyo bwiza. |

Ikibazo cya microcracks no kwangirika mugihe cyo gushushanya wafer nikibazo gikomeye mubikorwa bya semiconductor. Guhagarika umutima nimpamvu nyamukuru itera iki kintu, kuko gitera uduce duto kandi twangiritse hejuru ya wafer, bigatuma ibiciro byinganda byiyongera ndetse nubwiza bwibicuruzwa bikagabanuka.

Kugirango ukemure iki kibazo, ni ngombwa kugabanya imihangayiko yo kugabanya no gushyira mubikorwa uburyo bunoze bwo gukata, ibikoresho, nibisabwa. Kwita cyane kubintu nkibikoresho byuma, kugabanya umuvuduko, umuvuduko, nuburyo bukonje birashobora gufasha kugabanya imiterere ya microcrack no kuzamura umusaruro rusange wibikorwa. Byongeye kandi, ubushakashatsi burimo gukorwa muburyo bugezweho bwo guca ibintu, nko gushushanya laser, burimo gushakisha uburyo bwo kurushaho gukemura ibyo bibazo.

Nkibintu byoroshye, wafers ikunda guhinduka mumiterere yimbere iyo ihuye nubukanishi, ubushyuhe, cyangwa imiti, biganisha kuri microcrack. Nubwo ibyo bice bidashobora guhita bigaragara, birashobora kwaguka no kwangiza byinshi mugihe ibikorwa byo gukora bigenda bitera imbere. Iki kibazo kiba ikibazo cyane cyane mugihe cyo gupakira no gupima ibyakurikiyeho, aho ihindagurika ryubushyuhe hamwe nubundi buryo bwo gukanika imashini bishobora gutuma izo microcrake zihinduka mukuvunika kugaragara, birashoboka ko byananirana chip.

Kugabanya ibi byago, ni ngombwa kugenzura inzira yo guca witonze muguhindura ibipimo nko kugabanya umuvuduko, umuvuduko, nubushyuhe. Gukoresha uburyo buke bwo gukata, nko gushushanya laser, birashobora kugabanya imihangayiko kuri wafer kandi bikagabanya imiterere ya microcrack. Byongeye kandi, gushyira mubikorwa uburyo bunoze bwo kugenzura nka infragre scanning cyangwa amashusho ya X-ray mugihe cyo gushushanya wafer birashobora gufasha gutahura ibyo bice byambere mbere yuko bitera ibindi byangiritse.

Kwangirika hejuru ya wafer ni impungenge zikomeye mubikorwa byo gushushanya, kuko bishobora kugira ingaruka itaziguye kumikorere ya chip no kwizerwa. Ibyangiritse birashobora guterwa no gukoresha nabi ibikoresho byo gutema, ibipimo byo gutema nabi, cyangwa inenge yibintu biri muri wafer ubwayo. Tutitaye kubitera, ibyo byangiritse birashobora gutuma habaho impinduka mukurwanya amashanyarazi cyangwa ubushobozi bwumuzunguruko, bikagira ingaruka kumikorere rusange.

Kugira ngo ibyo bibazo bikemuke, ingamba ebyiri z'ingenzi zirimo gushakishwa:

1.Gukoresha ibikoresho byo gukata nibipimo: Ukoresheje ibyuma bikarishye, guhindura umuvuduko wo guca, no guhindura ubujyakuzimu bwo kugabanya, kwibanda kumaganya mugihe cyo gutema birashobora kugabanuka, bityo bikagabanya ibyangiritse.

2.Gushakisha uburyo bushya bwo guca: Ubuhanga buhanitse nko gukata lazeri no gukata plasma bitanga ibisobanuro neza mugihe bishobora kugabanya urwego rwibyangiritse kuri wafer. Izi tekinoroji zirimo kwigwa kugirango zishakire hamwe uburyo bwo kugera ku gukata gukabije mugihe hagabanijwe guhangayikishwa nubushyuhe nubukanishi kuri wafer.

Agace k'ingaruka z'ubushyuhe n'ingaruka zacyo ku mikorere

Muburyo bwo gukata amashyuza nka laser na plasma yo gukata, ubushyuhe bwo hejuru byanze bikunze butera ahantu hashyuha ubushyuhe hejuru ya wafer. Aka gace, aho ubushyuhe bugenda bugaragara, burashobora guhindura ibintu, bikagira ingaruka kumikorere ya chip.

Ingaruka za Zone yibasiwe nubushyuhe (TAZ):

Imiterere ya Crystal: Munsi yubushyuhe bwinshi, atome ziri mubikoresho bya wafer irashobora gutondekanya, bigatera kugoreka muburyo bwa kristu. Uku kugoreka guca intege ibikoresho, kugabanya imbaraga zumukanishi no gutuza, byongera ibyago byo kunanirwa chip mugihe cyo gukoresha.

Impinduka mubyiza byamashanyarazi: Ubushyuhe bwo hejuru burashobora guhindura ubwikorezi bwubwikorezi no kugenda mubikoresho bya semiconductor, bikagira ingaruka kumashanyarazi ya chip no gukora neza. Izi mpinduka zirashobora gutuma igabanuka ryimikorere ya chip, birashoboka ko idakwiriye kubyo igenewe.

Kugabanya izo ngaruka, kugenzura ubushyuhe mugihe cyo gukata, guhitamo ibipimo byo kugabanya, no gushakisha uburyo nko gukonjesha indege cyangwa kuvura nyuma yo gutunganya ni ingamba zingenzi zo kugabanya urugero rwingaruka ziterwa nubushyuhe no gukomeza ubusugire bwibintu.

Muri rusange, microcrack hamwe na zone ziterwa nubushyuhe nibibazo byingenzi muburyo bwa tekinoroji ya wafer. Ubushakashatsi bukomeje, hamwe niterambere ryikoranabuhanga hamwe ningamba zo kugenzura ubuziranenge, bizakenerwa kunoza ireme ryibicuruzwa bitwara imashanyarazi no kuzamura isoko ryabo.

Ingamba zo kugenzura ingaruka ziterwa nubushyuhe:

Kunoza uburyo bwo gutema ibice: Kugabanya umuvuduko nimbaraga zo kugabanya birashobora kugabanya neza ingano ya zone yubushyuhe (TAZ). Ibi bifasha mukugenzura ingano yubushyuhe butangwa mugihe cyo gutema, bigira ingaruka itaziguye kumiterere yibintu bya wafer.

Ikoranabuhanga rigezweho: Gukoresha ikoranabuhanga nka firime ya azote ikonjesha hamwe na microfluidic gukonjesha birashobora kugabanya cyane intera ya zone yubushyuhe. Ubu buryo bwo gukonjesha bufasha gukwirakwiza ubushyuhe neza, bityo bikarinda ibintu bya wafer kandi bikagabanya ibyangiritse.

Guhitamo Ibikoresho: Abashakashatsi barimo gushakisha ibikoresho bishya, nka karubone nanotubes na graphene, bifite ubushyuhe bwiza bwumuriro nimbaraga za mashini. Ibi bikoresho birashobora kugabanya ingaruka ziterwa nubushyuhe mugihe bitezimbere imikorere rusange ya chip.

Muncamake, nubwo akarere gaterwa nubushyuhe ningaruka byanze bikunze byogukoresha amashanyarazi, birashobora kugenzurwa neza hakoreshejwe uburyo bunoze bwo gutunganya no guhitamo ibikoresho. Ubushakashatsi bw'ejo hazaza bushobora kwibanda ku gutunganya neza no gutangiza uburyo bwo guca amashyuza kugirango ugere ku bipimo byiza bya wafer.

Ingamba zo Kuringaniza:

Kugera ku buringanire bwiza hagati yumusaruro wafer no gukora neza ni ikibazo gihoraho muburyo bwa tekinoroji ya wafer. Ababikora bakeneye gutekereza ku bintu byinshi, nkibikenewe ku isoko, ibiciro by’umusaruro, hamwe n’ubuziranenge bw’ibicuruzwa, kugira ngo bategure ingamba zifatika n’ibicuruzwa. Muri icyo gihe, kumenyekanisha ibikoresho bigezweho byo gutema, kuzamura ubumenyi bwabakozi, no kuzamura ubuziranenge bwibikoresho fatizo nibyingenzi mukubungabunga cyangwa no kuzamura umusaruro mugihe byongera umusaruro.

Ibibazo bizaza n'amahirwe:

Hamwe niterambere ryikoranabuhanga rya semiconductor, gukata wafer bihura nibibazo bishya n'amahirwe. Mugihe ingano ya chip igabanuka no kwishyira hamwe byiyongera, ibisabwa mukugabanya neza nubuziranenge bikura cyane. Icyarimwe, tekinoroji igaragara itanga ibitekerezo bishya mugutezimbere tekinike yo guca wafer. Ababikora bagomba gukomeza guhuza imbaraga nisoko ryiterambere ryikoranabuhanga, guhora bahindura kandi bagahindura ingamba zumusaruro hamwe nibipimo ngenderwaho kugirango bahuze isoko nibisabwa mubuhanga.

Mu gusoza, muguhuza ibitekerezo byifuzo byamasoko, ikiguzi cyumusaruro, nubwiza bwibicuruzwa, no mugutangiza ibikoresho nikoranabuhanga bigezweho, kongera ubumenyi bwabakoresha, no gushimangira kugenzura ibikoresho fatizo, ababikora barashobora kugera kuburinganire bwiza hagati yumusaruro wafer no gutanga umusaruro mugihe cyo gushushanya ibicuruzwa, biganisha ku musaruro w’ibicuruzwa bikoreshwa neza kandi byujuje ubuziranenge.

Ibihe bizaza:

Hamwe niterambere ryihuse ryikoranabuhanga, tekinoroji ya semiconductor iratera imbere kuburyo butigeze bubaho. Nintambwe ikomeye mubikorwa bya semiconductor, tekinoroji yo guca wafer yiteguye gutera imbere gushimishije. Urebye imbere, tekinoroji yo guca wafer iteganijwe kugera ku ntera igaragara neza, neza, ndetse nigiciro, itera imbaraga nshya mukuzamuka kwiterambere ryinganda ziciriritse.

Kongera Ubusobanuro:

Mugukurikirana ibisobanuro bihanitse, tekinoroji yo gukata wafer izakomeza gusunika imipaka yibikorwa bihari. Nukwiga byimazeyo uburyo bwa fiziki na chimique yuburyo bwo gutema no kugenzura neza ibipimo byo gutema, ibisubizo byiza byo gukata bizagerwaho kugirango byuzuze ibisabwa byumuzunguruko. Byongeye kandi, ubushakashatsi bwibikoresho bishya nuburyo bwo guca bizamura umusaruro nubuziranenge.

Kongera imbaraga:

Ibikoresho bishya byo gukata wafer bizibanda kubishushanyo mbonera kandi byikora. Kwinjiza sisitemu yo kugenzura igezweho hamwe na algorithms bizafasha ibikoresho guhita bihindura ibipimo byo gukata kugirango bihuze ibikoresho bitandukanye nibisabwa, bityo bizamura umusaruro neza. Udushya nka tekinoroji yo guca ibintu byinshi hamwe na sisitemu yo gusimbuza byihuse bizagira uruhare runini mu kuzamura imikorere.

Kugabanya ibiciro:

Kugabanya ibiciro nicyerekezo cyingenzi mugutezimbere tekinoroji yo guca wafer. Mugihe ibikoresho bishya nuburyo bwo gukata byatejwe imbere, ibiciro byibikoresho hamwe nogukoresha byateganijwe kugenzurwa neza. Byongeye kandi, kunoza imikorere yumusaruro no kugabanya igipimo cyakuweho bizarushaho kugabanya imyanda mugihe cyo gukora, bigatuma igabanuka ryumusaruro rusange.

Gukora Ubwenge na IoT:

Kwishyira hamwe mubikorwa byubwenge hamwe na enterineti yibintu (IoT) bizazana impinduka zihinduka muburyo bwa tekinoroji yo guca. Binyuze mu guhuza no gusangira amakuru hagati yibikoresho, buri ntambwe yuburyo bwo kubyara irashobora gukurikiranwa no gutezimbere mugihe nyacyo. Ibi ntabwo bizamura umusaruro gusa nubuziranenge bwibicuruzwa ahubwo binatanga ibigo byukuri guteganya isoko neza hamwe ninkunga ifata ibyemezo.

Mu bihe biri imbere, tekinoroji yo guca wafer izatera imbere cyane muburyo bwuzuye, neza, nigiciro. Iterambere rizateza imbere iterambere ry’inganda zikoresha kandi bizana udushya twinshi mu ikoranabuhanga kandi byorohereze umuryango w’abantu.

Igihe cyo kohereza: Ugushyingo-19-2024