Kirisiti imwe ntisanzwe muri kamere, kandi niyo ibaho, mubisanzwe ni nto cyane - mubisanzwe kuri milimetero (mm) - kandi kuyibona biragoye. Diyama ivugwa, emaragido, agate, nibindi, mubisanzwe ntabwo byinjira mumasoko, kereka nibikorwa byinganda; ibyinshi byerekanwe mungoro ndangamurage zo kumurika. Nyamara, kristu imwe imwe ifite agaciro gakomeye mu nganda, nka silikoni imwe ya kirisiti imwe mu nganda zuzuzanya, safiro ikunze gukoreshwa mu bikoresho bya optique, na karubide ya silikoni, igenda yiyongera mu gice cya gatatu cya semiconductor. Ubushobozi bwo kubyaza umusaruro-kristu imwe munganda ntabwo byerekana imbaraga gusa mubuhanga bwinganda nubuhanga ahubwo ni ikimenyetso cyubutunzi. Icyifuzo cyibanze kumusaruro umwe wa kirisiti mu nganda ni nini, kuko uru ni urufunguzo rwo kugabanya ibiciro neza. Hasi hari bimwe bikunze guhura na kristu imwe kumasoko:

1. Safiro imwe rukumbi

Safiro imwe ya kirisiti yerekeza kuri α-Al₂O₃, ifite sisitemu ya kirisiti itandatu, ubukana bwa Mohs bwa 9, hamwe n’imiti ihamye. Ntishobora gushonga mumazi ya acide cyangwa alkaline yangirika, irwanya ubushyuhe bwinshi, kandi ikagaragaza uburyo bwiza bwo kohereza urumuri, amashanyarazi, hamwe n’amashanyarazi.

Niba Al ion muri kristu isimbuwe na Ti na Fe ion, kristu igaragara nkubururu kandi yitwa safiro. Niba isimbuwe na Cr ion, igaragara umutuku kandi yitwa ruby. Nyamara, safiro yinganda ni nziza α-Al₂O₃, idafite ibara kandi ibonerana, nta mwanda.

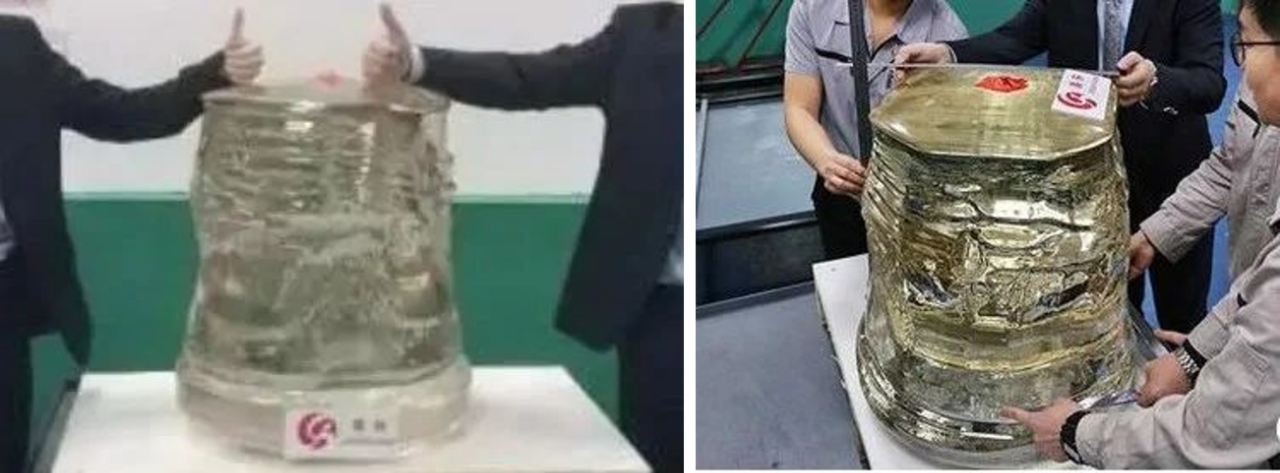

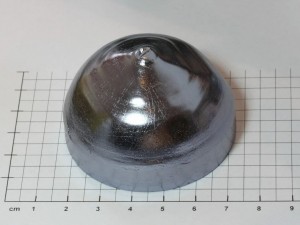

Safiro yinganda mubisanzwe ifata ishusho ya wafer, 400-700 mm z'ubugari na santimetero 4-8. Ibi bizwi nka wafer kandi byaciwe mubikoresho bya kristu. Yerekanwa hepfo ni ingot ikuwe mu itanura rimwe rya kirisiti, itarasya cyangwa ngo ikatwe.

Muri 2018, Isosiyete ikora ibikoresho bya elegitoroniki ya Jinghui muri Mongoliya Imbere yazamutse neza ku isi ibiro 450 binini cyane bya kirimbuzi nini ya safiro. Ikirahure kinini cya safiro mbere yisi yose yari kristal 350 kg yakozwe muburusiya. Nkuko bigaragara ku ishusho, iyi kristu ifite imiterere isanzwe, iragaragara neza, idafite ibice nimbibi zimbuto, kandi ifite ibibyimba bike.

2. Silicon imwe imwe

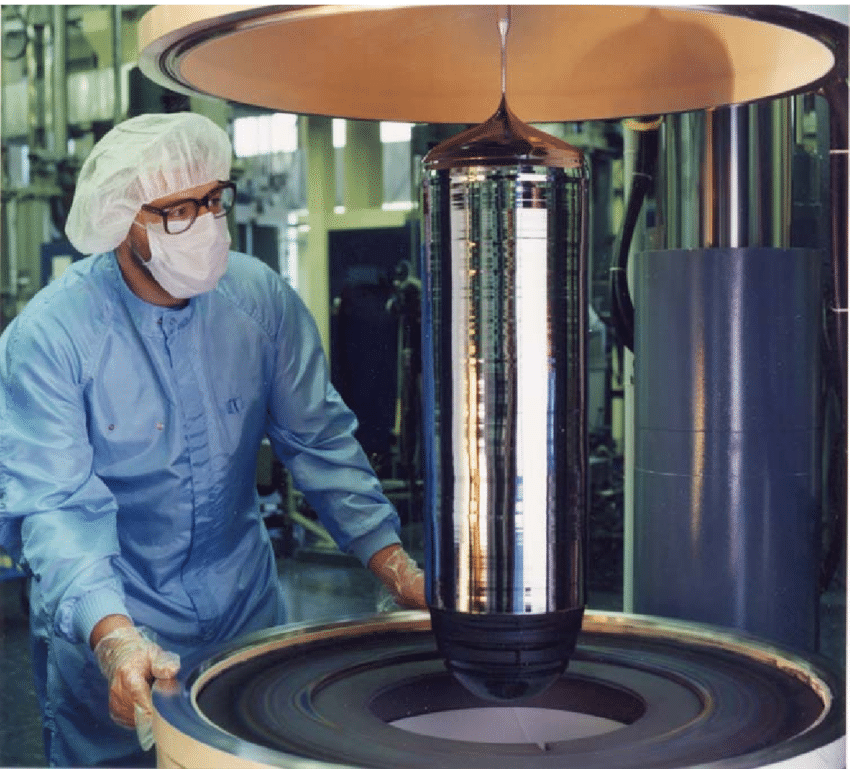

Kugeza ubu, silikoni imwe ya kirisiti ikoreshwa mu guhuza imiyoboro y’umuzunguruko ifite ubuziranenge bwa 99.9999999% kugeza kuri 99.999999999% (icyenda 9-11), hamwe na 420 kg silicon ingot igomba gukomeza imiterere isa na diyama. Muri kamere, na diyama imwe ya karat imwe (200 mg) ni gake.

Umusaruro rusange w’ibikoresho bya silicon imwe rukumbi wiganjemo amasosiyete atanu akomeye: Shin-Etsu w’Ubuyapani (28.0%), SUMCO y’Ubuyapani (21.9%), GlobalWafers yo muri Tayiwani (15.1%), SK Siltron yo muri Koreya yepfo (11,6%), na Siltronic yo mu Budage (11.3%). Ndetse n’umushinga munini wa semiconductor wafer mu gihugu cy’Ubushinwa, NSIG, ufite imigabane igera kuri 2,3% gusa. Nubwo bimeze bityo, nkumuntu mushya, ubushobozi bwayo ntibukwiye gusuzugurwa. Mu 2024, NSIG irateganya gushora imari mu mushinga wo kuzamura umusaruro wa mm 300 wa silicon wafer y’umuzunguruko uhuriweho, bikaba bivugwa ko ishoramari ingana na miliyari 13.2.

Nkibikoresho fatizo bya chip, intungamubiri-imwe-imwe ya kirisiti ya silicon ingoti igenda ihinduka kuva kuri santimetero 6 kugera kuri santimetero 12. Uruganda mpuzamahanga ruzwi cyane rwa chip, nka TSMC na GlobalFoundries, rukora chip ziva muri silicon ya santimetero 12 za waferi isoko rusange, mugihe waferi ya santimetero 8 zigenda zivaho. Umuyobozi wimbere mu gihugu SMIC aracyakoresha cyane cyane waferi-6. Kugeza ubu, SUMCO yo mu Buyapani yonyine niyo ishobora kubyara ubuziranenge bwa santimetero 12 za wafer.

3. Gallium Arsenide

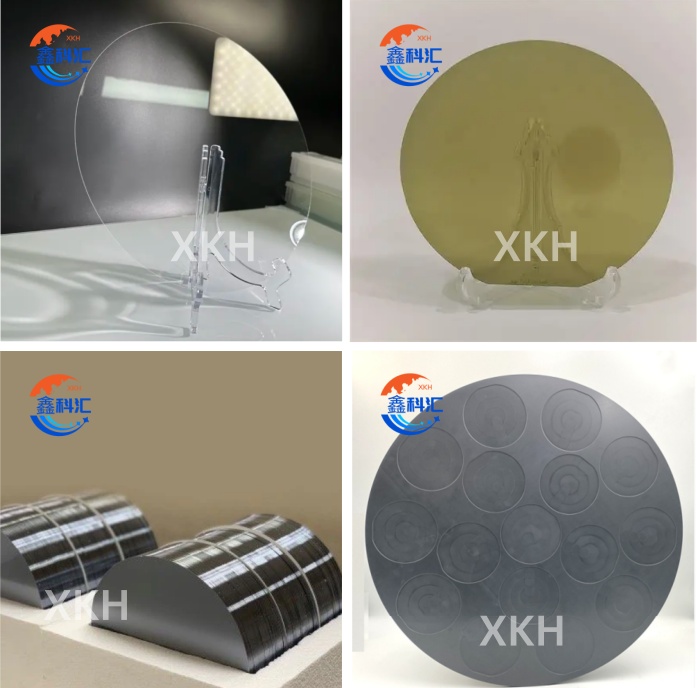

Wafers ya Gallium arsenide (GaAs) nigikoresho cyingenzi cya semiconductor, kandi ubunini bwacyo nibintu byingenzi mugutegura.

Kugeza ubu, wafers ya GaAs isanzwe ikorwa mubunini bwa santimetero 2, santimetero 3, santimetero 4, santimetero 6, santimetero 8, na santimetero 12. Muri ibyo, waferi ya santimetero 6 nimwe mubikoreshwa cyane.

Umubare ntarengwa wa diameter ya kristu imwe ikura nuburyo bwa Horizontal Bridgman (HB) mubusanzwe ni santimetero 3, mugihe uburyo bwa Liquid-Encapsulated Czochralski (LEC) bushobora kubyara kristu imwe kugeza kuri santimetero 12. Ariko, gukura kwa LEC bisaba ibikoresho byinshi kandi bitanga kristu idafite uburinganire nubucucike bukabije. Uburyo bwa Vertical Gradient Freeze (VGF) hamwe na Vertical Bridgman (VB) birashobora gutanga ubu kristu imwe kugeza kuri santimetero 8 z'umurambararo, hamwe nuburyo bumwe hamwe n'ubucucike buri munsi.

Ikoranabuhanga mu gukora ibicuruzwa bya santimetero 4 na santimetero 6 za gafs isukuye ya wafers ikunzwe cyane cyane n’amasosiyete atatu: Ubuyapani Sumitomo Electric Industries, Ubudage bwa Freiberger Compound Materials, na AXT yo muri Amerika. Kugeza 2015, insimburangingo ya santimetero 6 zimaze kuba hejuru ya 90% by'imigabane ku isoko.

Muri 2019, isoko rya substrate ya GaAs ku isi ryiganjemo Freiberger, Sumitomo, na Beijing Tongmei, imigabane y'isoko ikaba 28%, 21%, na 13%. Dukurikije ibigereranyo byakozwe n’ikigo ngishwanama Yole, kugurisha ku isi hose kwa GaAs (byahinduwe bihwanye na santimetero 2) mu mwaka wa 2019 bikaba biteganijwe ko bizarenga miliyoni 35 mu 2025.

4. Silicon Carbide imwe rukumbi

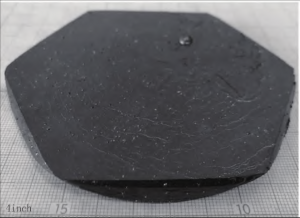

Kugeza ubu, isoko irashobora gushyigikira byimazeyo gukura kwa santimetero 2 na santimetero 3 za silicon karbide (SiC) kristu imwe. Ibigo byinshi byatangaje ko byiyongereyeho iterambere rya santimetero 4H zo mu bwoko bwa SiC imwe ya kristu imwe, ibyo bikaba byerekana ko Ubushinwa bwageze ku rwego rw’isi mu ikoranabuhanga rya SiC. Ariko, haracyari icyuho gikomeye mbere yubucuruzi.

Mubisanzwe, ingunguru ya SiC ikura muburyo bwamazi-fase ni ntoya, hamwe nubunini kurwego rwa santimetero. Iyi nayo nimpamvu yikiguzi kinini cya wafers ya SiC.

X. Twifashishije ubushobozi bwinganda zahurijwe hamwe, dutanga umusaruro mwinshi wa safiro waferi, karubide ya karubide ya silicon, hamwe na wafers ya ultra-high-purity silicon wafers, ishyigikiwe nibisubizo byabugenewe nko gukata ibicuruzwa, gutwikira hejuru, hamwe no guhimba geometrike igoye kugirango bikemure ibidukikije bikabije muri sisitemu ya laser, guhimba semiconductor, no gukoresha ingufu zishobora gukoreshwa.

Dukurikije amahame yubuziranenge, ibicuruzwa byacu biranga micron-urwego rwukuri,> 1500 ° C ihindagurika ryumuriro, hamwe no kurwanya ruswa irenze, byemeza kwizerwa mubikorwa bibi. Twongeyeho, dutanga ibice bya quartz, ibyuma / ibikoresho bitari ibyuma, nibindi bikoresho byo mu rwego rwa semiconductor, bigatuma habaho impinduka zidasubirwaho kuva prototyping kugera kumusaruro rusange kubakiriya binganda.

Igihe cyo kohereza: Kanama-29-2025