Intangiriro kuri karubide ya silicon

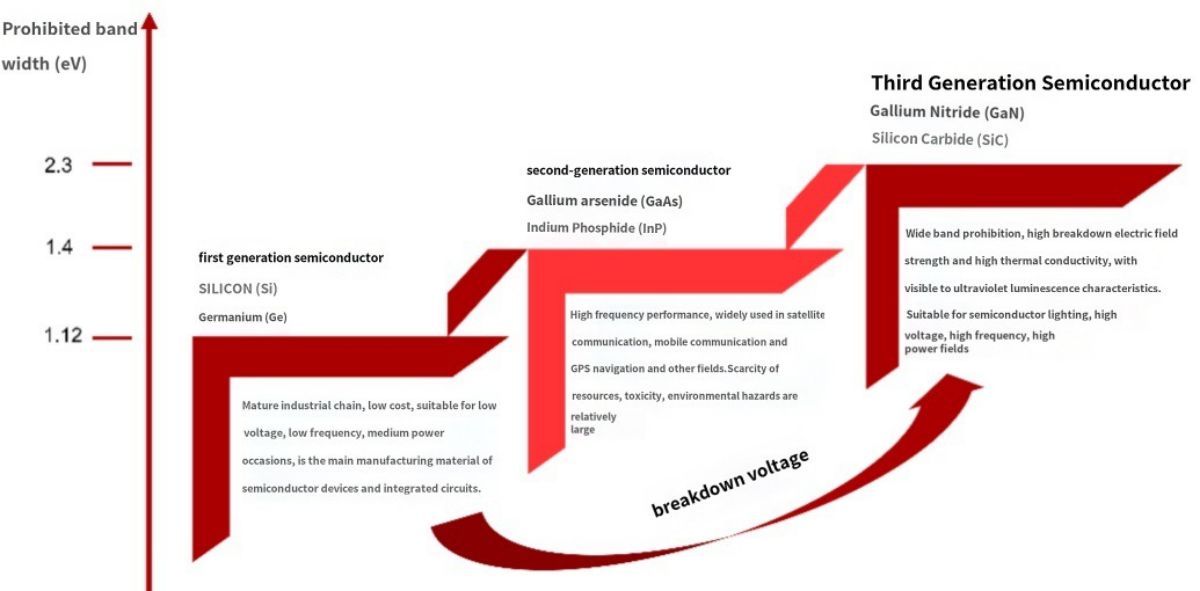

Carbide ya Silicon (SiC) nigikoresho cya semiconductor igizwe na karubone na silikoni, nikimwe mubikoresho byiza byo gukora ubushyuhe bwinshi, inshuro nyinshi, ingufu nyinshi hamwe n’ibikoresho bya voltage nyinshi. Ugereranije nibikoresho gakondo bya silicon (Si), ikinyuranyo cya bande ya silicon karbide yikubye inshuro 3 icya silikoni. Amashanyarazi yumuriro yikubye inshuro 4-5 ya silicon; Umuvuduko wa voltage wikubye inshuro 8-10 za silicon; Igipimo cyo kwiyuzuzamo cya elegitoronike cyikubye inshuro 2-3 za silikoni, yujuje ibikenerwa ninganda zigezweho kugirango ingufu nyinshi, voltage nini na frequency nyinshi. Ikoreshwa cyane cyane mugukora ibintu byihuta, byihuta cyane, imbaraga nyinshi kandi bitanga urumuri rwa elegitoroniki. Imirima yo kumanuka yamashanyarazi irimo gride yubwenge, ibinyabiziga bishya byingufu, ingufu zumuyaga zifotora, itumanaho rya 5G, nibindi.

Kurwanya ubushyuhe bwinshi. Ubugari bwa bande ya silicon karbide yikubye inshuro 2-3 za silikoni, electron ntizoroshye guhinduka mubushyuhe bwinshi, kandi irashobora kwihanganira ubushyuhe bwo hejuru, kandi ubushyuhe bwumuriro wa karubide ya silikoni bwikubye inshuro 4-5 za silikoni, bigatuma ubushyuhe bwibikoresho bikwirakwizwa byoroshye kandi nubushyuhe bwo gukora bukaba hejuru. Ubushyuhe bwo hejuru burashobora kongera ingufu zumuriro mugihe ugabanya ibisabwa kuri sisitemu yo gukonjesha, bigatuma itumanaho ryoroha kandi rito.

Ihangane n'umuvuduko ukabije. Amashanyarazi yamashanyarazi imbaraga za karubide ya silikoni yikubye inshuro 10 ya silikoni, ishobora kwihanganira ingufu nyinshi kandi ikwiriye kubikoresho bikoresha ingufu nyinshi.

Kurwanya inshuro nyinshi. Carbide ya Silicon ifite umuvuduko wa elegitoronike yuzuye inshuro ebyiri ugereranije na silikoni, bigatuma habaho umurizo wigihe mugihe cyo guhagarika, bishobora kunoza neza uburyo bwo guhinduranya igikoresho kandi bikamenya miniaturizasi yibikoresho.

Gutakaza ingufu nke. Ugereranije nibikoresho bya silicon, karbide ya silicon ifite bike cyane kubirwanya kandi bike kubihombo. Muri icyo gihe, ubugari burebure bwa burebure bwa silicon karbide bigabanya cyane imiyoboro yamenetse no gutakaza ingufu. Mubyongeyeho, ibikoresho bya silicon karbide ntabwo bifite ibintu bikurikirana mugihe cyo guhagarika, kandi igihombo cyo guhinduranya ni gito.

Silicon carbide inganda

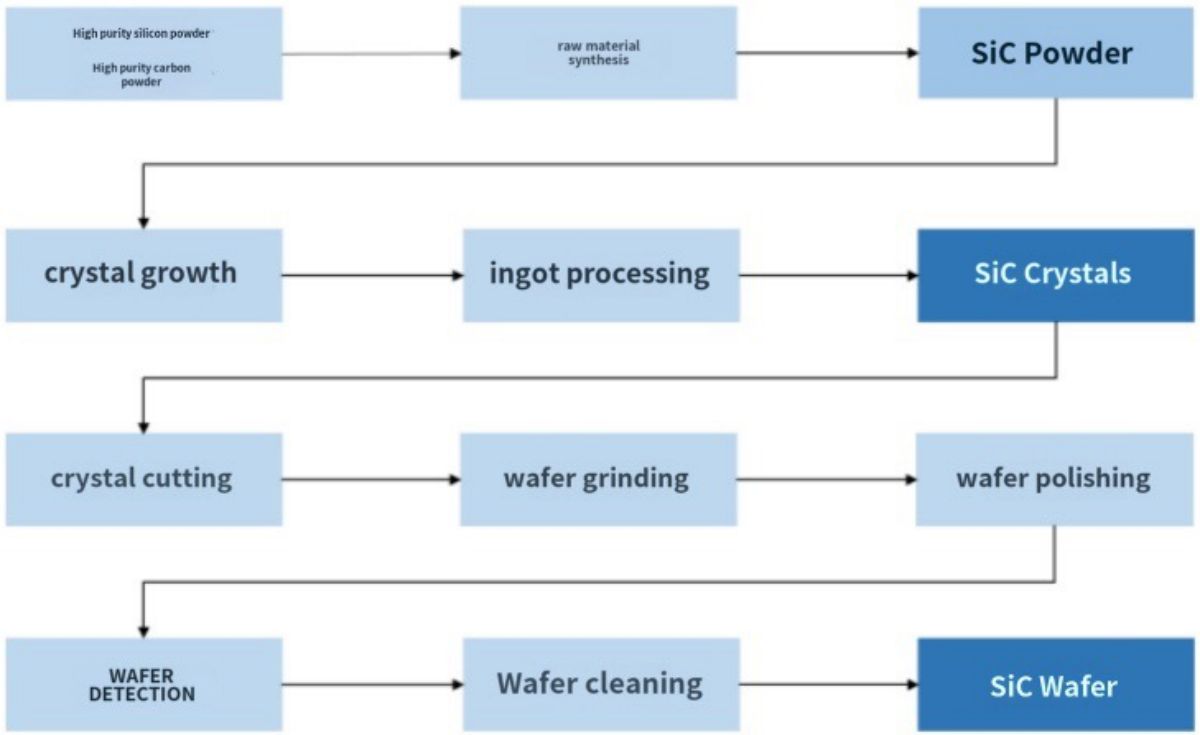

Harimo cyane cyane substrate, epitaxy, igishushanyo mbonera, gukora, kashe nibindi. Carbide ya silicon kuva mubikoresho kugeza kumashanyarazi ya semiconductor izagira imikurire imwe ya kristu, gukata ingot, gukura epitaxial, igishushanyo cya wafer, gukora, gupakira nibindi bikorwa. Nyuma yo guhuza ifu ya karibide ya silicon, ingot ya karibide ya silicon ikorwa mbere, hanyuma insimburangingo ya silicon karbide iboneka mugukata, gusya no gusya, hanyuma urupapuro rwa epitaxial rukabonwa no gukura kwa epitaxial. Epitaxial wafer ikozwe muri karubide ya silicon ikoresheje lithographie, etching, ion ionation, passivation yicyuma nibindi bikorwa, wafer yaciwemo gupfa, igikoresho kirapakirwa, kandi igikoresho gihurizwa mugikonoshwa kidasanzwe hanyuma giteranyirizwa muri module.

Hejuru yumurongo winganda 1: substrate - gukura kwa kristu ninzira yibanze ihuza inzira

Silicon carbide substrate ihwanye na 47% yikiguzi cyibikoresho bya karibide ya silicon, inzitizi zikomeye zikora tekiniki, agaciro gakomeye, nizo ntandaro yigihe kizaza kinini mu nganda za SiC.

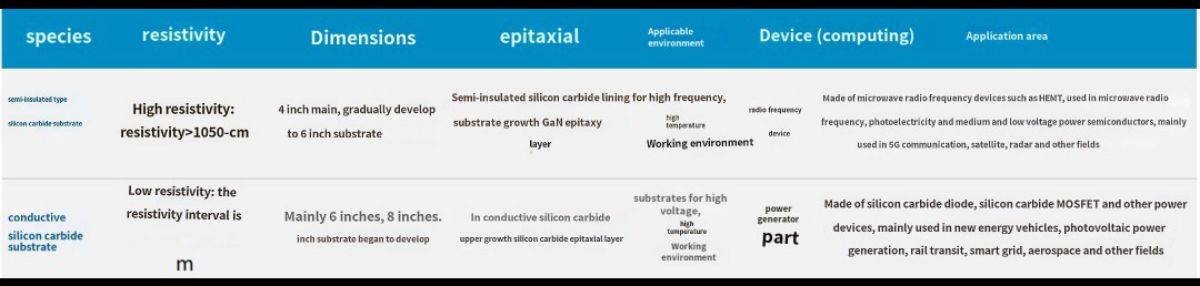

Urebye itandukaniro ryumutungo wa electrochemicique, ibikoresho bya silicon karbide substrate birashobora kugabanywamo insimburangingo (akarere kirwanya 15 ~ 30mΩ · cm) hamwe nubutaka bwakorewe igice (kurwanya hejuru ya 105Ω · cm). Ubu bwoko bubiri bwa substrate bukoreshwa mugukora ibikoresho byihariye nkibikoresho byamashanyarazi nibikoresho bya radiyo yumurongo nyuma yo gukura kwa epitaxial. Muri byo, insimburangingo ya silicon karbide substrate ikoreshwa cyane cyane mugukora ibikoresho bya gallium nitride RF, ibikoresho byamashanyarazi nibindi. Mugukuza gan epitaxial layer kuri sisitemu ya SIC igice cya kabiri, isahani ya epitaxial plaque irategurwa, ishobora kurushaho gutegurwa mubikoresho bya HEMT gan iso-nitride RF. Imiyoboro ya silicon karbide substrate ikoreshwa cyane mugukora ibikoresho byamashanyarazi. Bitandukanye nuburyo gakondo bwo gukora ibikoresho bya silicon yamashanyarazi, ibikoresho byamashanyarazi ya silicon ntibishobora gukorwa muburyo butaziguye kuri silicon carbide substrate, icyuma cya silicon carbide epitaxial layer igomba guhingwa kuri substrate yiyobora kugirango ibone urupapuro rwa epicaxial silicon, kandi epitaxial ikorerwa kuri diode ya Schottky, MOSFET, IGBT.

Ifu ya karibide ya silikoni yashizwemo ivuye mu ifu ya karubone isukuye cyane nifu ya silikoni isukuye cyane, kandi ingano zitandukanye za silicon karbide ingot zahinzwe munsi yubushyuhe budasanzwe, hanyuma insimburangingo ya silikoni yakozwe muburyo butandukanye bwo gutunganya. Inzira yibanze ikubiyemo:

Sintezezike yibikoresho: Ifu ya silicon yuzuye-yuzuye ya toner ivanze ukurikije formulaire, kandi reaction ikorerwa mubyumba byabigenewe munsi yubushyuhe bwo hejuru hejuru ya 2000 ° C kugirango ihuze ibice bya karubide ya silicon ifite ubwoko bwa kristu nubunini bwihariye. Noneho unyuze mu kumenagura, gusuzuma, gusukura nibindi bikorwa, kugirango wuzuze ibisabwa bya silicon karbide yifu yifu yibikoresho fatizo.

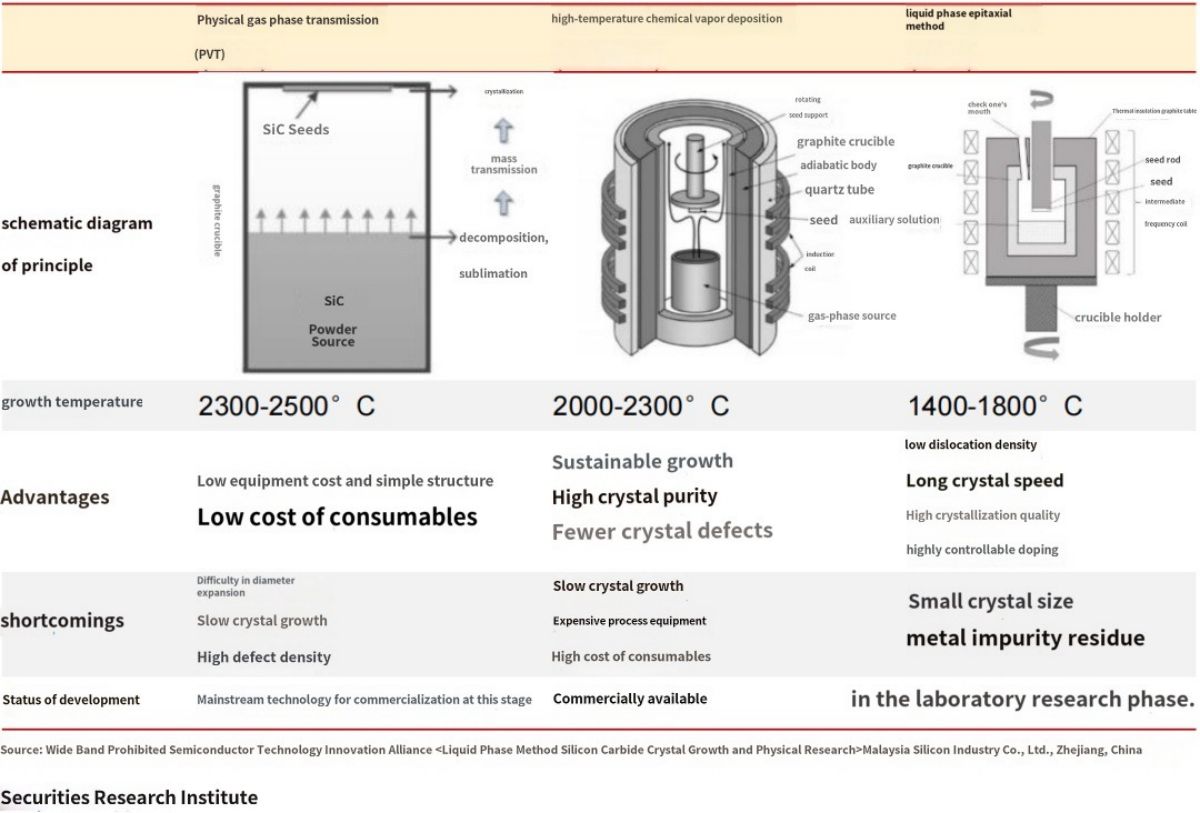

Gukura kwa Crystal ninzira yibanze yo gukora silicon karbide substrate yinganda, igena imiterere yamashanyarazi ya silicon karbide substrate. Kugeza ubu, uburyo nyamukuru bwo gukura kwa kirisiti ni ihererekanyabubasha ryimyuka yumubiri (PVT), ubushyuhe bwo hejuru bwimyuka mvaruganda (HT-CVD) hamwe na epitaxy yamazi (LPE). Muri byo, uburyo bwa PVT nuburyo bwibanze bwo kuzamura ubucuruzi bwa SiC substrate muri iki gihe, hamwe nubuhanga buhanitse kandi bukoreshwa cyane mubuhanga.

Gutegura substrate ya SiC biragoye, biganisha ku giciro cyayo kinini

Kugenzura umurima w'ubushyuhe biragoye: Gukura kw'inkoni ya kristu ikenera 1500 only gusa, mugihe inkoni ya kirisiti ya SiC igomba guhingwa ku bushyuhe bwo hejuru hejuru ya 2000 ℃, kandi hariho isomeri zirenga 250 za SiC, ariko ibyingenzi 4H-SiC imwe rukumbi ya kristu yo gukora ibikoresho byamashanyarazi, niba bitagenzuwe neza, bizabona izindi nyubako za kirisiti. Byongeye kandi, ubushyuhe bwa gradient muburyo bukomeye bugena igipimo cyo kwimura SiC sublimation hamwe nuburyo bwo gukura hamwe nuburyo bwo gukura bwa atome ya gaze kuri interineti ya kirisiti, bigira ingaruka kumikurire ya kristu hamwe nubwiza bwa kristu, bityo rero birakenewe ko hashyirwaho uburyo bunoze bwo kugenzura ubushyuhe bwumurima. Ugereranije nibikoresho bya Si, itandukaniro mubikorwa bya SiC naryo riri mubikorwa byubushyuhe bwo hejuru nko gutera ubushyuhe bwo hejuru ion, gushiramo ubushyuhe bwinshi, gukora ubushyuhe bwinshi, hamwe nuburyo bukomeye bwa mask busabwa nubushyuhe bwo hejuru.

Gukura gahoro gahoro: umuvuduko wubwiyongere bwa Si kristaliste ishobora kugera kuri 30 ~ 150mm / h, kandi umusaruro wa 1-3m silicon kristal ya kristu ifata umunsi umwe gusa; Inkoni ya kirisiti ya SiC hamwe nuburyo bwa PVT nkurugero, umuvuduko wubwiyongere ni 0.2-0.4mm / h, iminsi 7 yo gukura munsi ya 3-6cm, umuvuduko wubwiyongere uri munsi ya 1% yibikoresho bya silicon, ubushobozi bwo gukora ni buke cyane.

Ibicuruzwa byinshi hamwe numusaruro muke: ibipimo byibanze bya SiC substrate harimo ubucucike bwa microtubule, ubucucike bwa dislokisiyo, kurwanya, kurupapuro, ububobere buke, nibindi.

Ibikoresho bifite ubukana bwinshi, ubwitonzi bukabije, igihe kirekire cyo gukata no kwambara cyane: SiC Mohs ubukana bwa 9.25 ni iya kabiri nyuma ya diyama, ibyo bigatuma habaho kwiyongera gukomeye mubibazo byo gutema, gusya no gusya, kandi bisaba amasaha agera kuri 120 yo guca ibice 35-40 byimbuto ya 3cm. Mubyongeyeho, kubera ubwinshi bwa SiC, imyenda yo gutunganya wafer izaba myinshi, kandi igipimo gisohoka ni 60% gusa.

Iterambere ryiterambere: Ingano yiyongera + igabanuka ryibiciro

Isoko rya SiC kwisi yose umurongo wa santimetero 6 zirakura, kandi ibigo bikomeye byinjiye mumasoko ya santimetero 8. Imishinga yiterambere ryimbere mu gihugu ni santimetero 6. Kugeza ubu, nubwo amasosiyete menshi yo mu gihugu akomeje gushingira ku murongo w’ibicuruzwa bya santimetero 4, ariko inganda zigenda ziyongera kugeza kuri santimetero 6, hamwe n’ikura ry’ikoranabuhanga rikoresha ibikoresho bya santimetero 6, ikoranabuhanga rya SiC substrate yo mu gihugu naryo riragenda ritezimbere ubukungu bw’ibipimo by’imirongo minini y’ibicuruzwa bizagaragazwa, kandi icyuho cy’imbere mu gihugu cya santimetero 6 cyagabanutse kugeza ku myaka 7. Ingano nini ya wafer irashobora kuzana ubwiyongere bwumubare umwe wa chip imwe, kuzamura igipimo cyumusaruro, no kugabanya igipimo cyimbuto, kandi ikiguzi cyubushakashatsi niterambere ndetse nigihombo cyumusaruro kizagumaho hafi 7%, bityo bizamura imikoreshereze ya wafer.

Haracyari ingorane nyinshi mugushushanya ibikoresho

Ubucuruzi bwa diode ya SiC bugenda butera imbere buhoro buhoro, kuri ubu, abatari bake bo mu gihugu bakoze ibicuruzwa bya SiC SBD, ibicuruzwa bito n'ibiciriritse bya SiC SBD bifite umutekano uhamye, mu modoka OBC, gukoresha SiC SBD + SI IGBT kugira ngo bigere ku bucucike buriho. Kugeza ubu, nta mbogamizi ziri mu gishushanyo mbonera cy’ibicuruzwa bya SiC SBD mu Bushinwa, kandi ikinyuranyo n’ibihugu by’amahanga ni gito.

SiC MOS iracyafite ingorane nyinshi, haracyari icyuho hagati ya SiC MOS n’abakora mu mahanga, kandi urubuga rukora inganda ruracyubakwa. Kugeza ubu, ST, Infineon, Rohm nizindi 600-1700V SiC MOS zimaze kugera ku musaruro mwinshi kandi zashyizweho umukono kandi zoherezwa mu nganda nyinshi zikora inganda, mu gihe igishushanyo mbonera cy’imbere mu gihugu cya SiC MOS cyarangiye ahanini, abakora ibishushanyo mbonera bakorana na fab ku cyiciro cya wafer, kandi nyuma yo kugenzura abakiriya biracyakenewe igihe runaka, bityo hakaba hakiri igihe kinini cyo kugurisha ibicuruzwa binini.

Kugeza ubu, imiterere ya planari niyo nzira nyamukuru ihitamo, kandi ubwoko bwumwobo bukoreshwa cyane murwego rwumuvuduko mwinshi mugihe kizaza. Imiterere yimigambi Abakora SiC MOS nibyinshi, imiterere ya planar ntabwo yoroshye kubyara ibibazo byo gusenyuka byaho ugereranije na groove, bigira ingaruka kumurimo wakazi, kumasoko ari munsi ya 1200V ifite agaciro gakomeye ko gukoreshwa, kandi imiterere ya planar iroroshye muburyo bwo gukora, kugirango ihuze nibikorwa no kugenzura ibiciro muburyo bubiri. Igikoresho cya groove gifite ibyiza byo kwipimisha cyane parasitike, kwihuta kwihuta, gutakaza bike no gukora cyane.

2 - Amakuru ya wafer ya SiC

Silicon karbide yumusaruro niterambere ryigurisha, witondere ubusumbane bwimiterere hagati yo gutanga nibisabwa

Ubwiyongere bwihuse bwibisabwa ku isoko rya elegitoroniki y’umuvuduko mwinshi kandi ufite ingufu nyinshi, icyuho cy’umubiri cy’ibikoresho bya semiconductor gishingiye kuri silicon cyagiye kigaragara buhoro buhoro, kandi ibikoresho bya semiconductor byo mu gisekuru cya gatatu byerekanwe na karubide ya silicon (SiC) byahindutse inganda. Urebye imikorere yibikorwa, karbide ya silicon ifite inshuro 3 ubugari bwikigero cyibikoresho bya silicon, inshuro 10 imbaraga zikomeye zumuriro wumuriro wamashanyarazi, inshuro 3 ubushyuhe bwumuriro, bityo ibikoresho bya karbide ya silikoni bikwiranye numuvuduko mwinshi, umuvuduko mwinshi, ubushyuhe bwinshi nibindi bikorwa, bifasha kunoza imikorere nubucucike bwimbaraga za sisitemu ya elegitoroniki.

Kugeza ubu, diode ya SiC na SiC MOSFETs yagiye buhoro buhoro ku isoko, kandi hari ibicuruzwa byinshi bikuze, muri byo harimo diode ikoreshwa cyane aho gukoresha diode ishingiye kuri silikoni mu bice bimwe na bimwe kuko idafite inyungu zo kwishyurwa; SiC MOSFET nayo ikoreshwa buhoro buhoro mumodoka, kubika ingufu, kwishyiriraho ikirundo, gufotora no mubindi bice; Mu rwego rwo gukoresha amamodoka, inzira ya modularisation iragenda irushaho kwigaragaza, imikorere isumba iyindi ya SiC ikeneye gushingira kubikorwa byo gupakira bigezweho kugirango bigerweho, muburyo bwa tekiniki hamwe nigikonoshwa gikuze gifatika nkibisanzwe, ejo hazaza cyangwa iterambere rya kashe ya plastike, ibiranga iterambere ryihariye birakwiriye muburyo bwa SiC.

Silicon carbide igiciro cyo kugabanuka umuvuduko cyangwa birenze ibitekerezo

Ikoreshwa ryibikoresho bya karibide ya silicon bigarukira cyane cyane kubiciro bihanitse, igiciro cya SiC MOSFET kurwego rumwe cyikubye inshuro 4 ugereranije n’icya Si gishingiye kuri IGBT, ibi biterwa nuko inzira ya karubide ya silikoni igoye, aho imikurire ya kirisiti imwe na epitaxial idakabije gusa ku bidukikije, ariko kandi n’ikigereranyo cyo gukura kigenda gahoro gahoro. Ukurikije ibintu byihariye biranga hamwe na tekinoroji yo gutunganya idakuze, umusaruro wa substrate yo mu gihugu uri munsi ya 50%, kandi ibintu bitandukanye biganisha ku biciro byo hejuru ndetse n’ibiciro bya epitaxial.

Nyamara, ibiciro byibikoresho bya karibide ya silicon nibikoresho bishingiye kuri silikoni bitandukanye cyane na diametrica, ibiciro bya substrate na epitaxial byumuyoboro wimbere bingana na 47% na 23% byibikoresho byose uko bikurikirana, byose hamwe bigera kuri 70%, igishushanyo mbonera cyibikoresho, gukora no gufunga imiyoboro yinyuma yibice 30% gusa, ibiciro byumusaruro wibikoresho bishingiye kuri silikoni byibanda cyane kuri 50% byinganda zikoreshwa. Ikintu cyerekana agaciro ka silicon karbide yinganda zinganda hejuru bivuze ko abakora epitaxy yo hejuru yo hejuru bafite uburenganzira bwibanze bwo kuvuga, nurufunguzo rwimiterere yibikorwa byimbere mu gihugu ndetse n’amahanga.

Duhereye ku buryo bugaragara ku isoko, kugabanya igiciro cya karubide ya silicon, usibye kunoza karbide ya silicon karbide ndende no gutemagura, ni ukwagura ubunini bwa wafer, ari nayo nzira ikuze y’iterambere rya semiconductor mu bihe byashize, amakuru ya Wolfspeed yerekana ko karibide ya silikoni yo kuzamura kuva kuri santimetero 6 kugeza kuri santimetero 8, umusaruro wa chip ukwiye ushobora kwiyongera na 80% -90%. Irashobora kugabanya igiciro cyahurijwe hamwe 50%.

2023 izwi nka "santimetero 8 za SiC umwaka wa mbere", muri uyu mwaka, abakora karbide ya silicon yo mu gihugu ndetse n’amahanga yihutisha imiterere ya karbide ya silicon ya santimetero 8, nka Wolfspeed ishoramari ry’amadorari miliyoni 14.55 y’amadolari yo kwagura umusaruro wa karuboni ya silicon, igice kinini cyacyo kikaba ari ukubaka uruganda rukora ibyuma bya santimetero 8 za SiC; Imbere mu gihugu Tianyue Advanced na Tianke Heda na bo basinyanye amasezerano y'igihe kirekire na Infineon yo gutanga insimburangingo ya karubide ya santimetero 8 mu gihe kiri imbere.

Guhera muri uyu mwaka, karbide ya silicon izihuta kuva kuri santimetero 6 kugera kuri santimetero 8, Wolfspeed iteganya ko mu 2024, chip ya unit igiciro cya santimetero 8 ugereranije na chip ya unit ya santimetero 6 substrate muri 2022 izagabanukaho hejuru ya 60%, kandi igabanuka ry’ibiciro rizakomeza gufungura isoko ry’imikorere, nk'uko Ji Bond Consulting data yabigaragaje. Kugeza ubu isoko ryibicuruzwa 8-santimetero biri munsi ya 2%, kandi biteganijwe ko umugabane w isoko uziyongera kugera kuri 15% muri 2026.

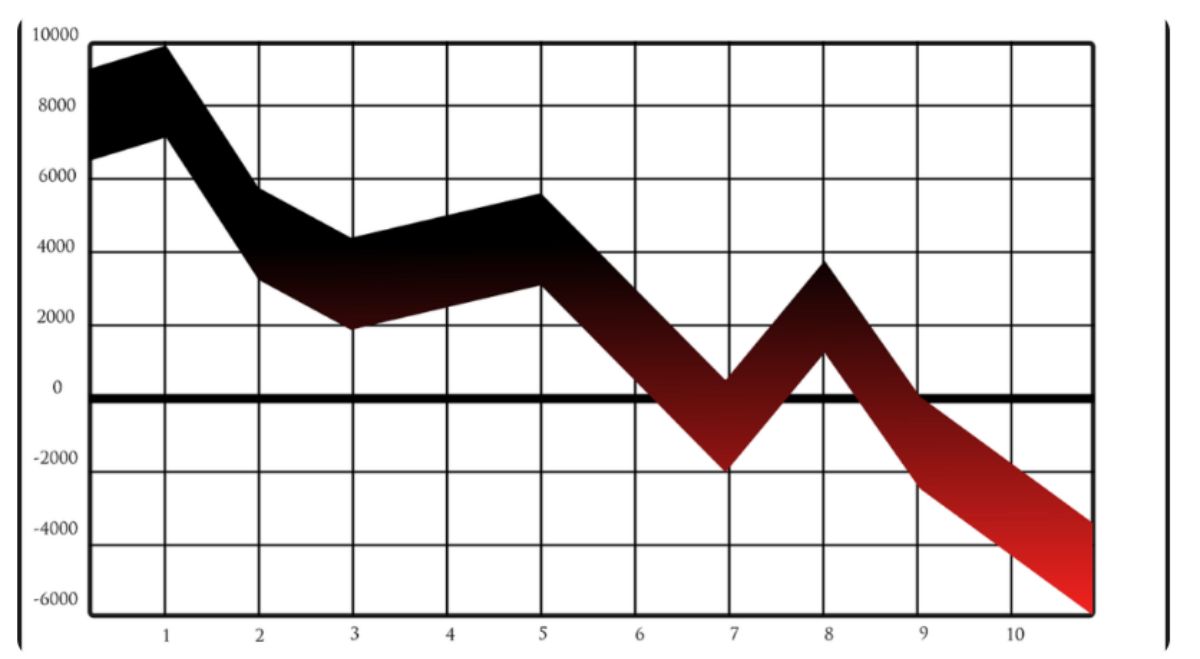

Mubyukuri, igipimo cyo kugabanuka kwibiciro bya silicon karbide substrate irashobora kurenza abantu benshi babitekereza, isoko ryubu rya substrate ya santimetero 6 ni 4000-5000 yuan / igice, ugereranije nintangiriro yumwaka ryagabanutse cyane, biteganijwe ko rizamanuka munsi yu 4000 yu mwaka utaha, birakwiye ko tumenya ko bamwe mubakora ibicuruzwa kugirango babone isoko rya mbere, bagabanije igiciro cyibicuruzwa munsi yintambara, hafunguye igiciro cyibiciro munsi yintambara byaragereranijwe bihagije mumashanyarazi make, abakora mu gihugu no mumahanga baraguka cyane mubushobozi bwo kubyaza umusaruro, cyangwa bakareka silicon karbide substrate ikaboneka hakiri kare kuruta uko wabitekerezaga.

Igihe cyo kohereza: Mutarama-19-2024