Ikibazo: Ni ubuhe buryo bw'ikoranabuhanga bukoreshwa mu gukata no gutunganya SiC wafer?

A:Carbide (SiC) ifite ubukana bwa kabiri nyuma ya diyama kandi ifatwa nkibikoresho bikomeye kandi byoroshye. Uburyo bwo gukata, burimo gukata kristu ikuze mo waferi yoroheje, biratwara igihe kandi bikunda gukata. Nintambwe yambere muriSiCgutunganya kristu imwe, ubwiza bwo gukata bigira uruhare runini nyuma yo gusya, gusya, no kunanuka. Gukata akenshi bizana ibice byo hejuru hamwe nubutaka, byongera igipimo cyo kumena wafer nigiciro cyumusaruro. Kubwibyo, kugenzura ibyangiritse hejuru mugihe cyo gukata ningirakamaro mugutezimbere ibikoresho bya SiC.

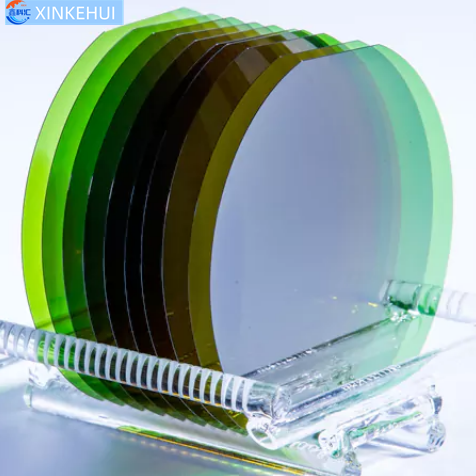

Kugeza ubu uburyo bwo gukata bwa SiC burimo gukosora-gukuramo, gukata ubusa-gukata, gukata lazeri, kwimura ibice (gutandukanya imbeho), no gukata amashanyarazi. Muri ibyo, gusubiranamo insinga nyinshi hamwe na diyama ihamye ni uburyo bukoreshwa cyane mugutunganya SiC imwe rukumbi. Nyamara, uko ingano ya ingot igera kuri santimetero 8 no hejuru, kubona insinga gakondo biba bike cyane kubera ibikoresho bikenerwa cyane, ibiciro, hamwe nubushobozi buke. Harakenewe byihutirwa tekinoroji ihendutse, igihombo gito, ikora neza.

Ikibazo: Ni izihe nyungu zo gukata lazeri kurenza gukata insinga nyinshi?

Igisubizo: Gukoresha insinga gakondo ikataSiC ingotku cyerekezo cyihariye mubice ucamo microne magana. Ibice noneho birahinduka hasi hifashishijwe ibishishwa bya diyama kugirango bikureho ibimenyetso byangiritse no kwangirika kwisi, hanyuma bikurikirwa no gukanika imashini (CMP) kugirango bigere ku isi, hanyuma amaherezo bisukurwa kugirango ubone wafer ya SiC.

Nyamara, kubera ubukana bwa SiC nubukonje bwinshi, izi ntambwe zirashobora gutera byoroshye kurwana, guturika, kongera umuvuduko wamenetse, ibiciro byumusaruro mwinshi, kandi bikavamo ubukana bukabije kandi bwanduye (ivumbi, amazi mabi, nibindi). Byongeye kandi, kubona insinga biratinda kandi bifite umusaruro muke. Ikigereranyo cyerekana ko gukata insinga gakondo bigera kuri 50% gusa yo gukoresha ibikoresho, kandi kugeza 75% byibikoresho byabuze nyuma yo gusya no gusya. Amakuru yambere y’umusaruro w’amahanga yerekanaga ko bishobora gufata iminsi igera kuri 273 yumusaruro uhoraho wamasaha 24 kugirango ubyare 10,000 waferi-bitwara igihe kinini.

Imbere mu gihugu, amasosiyete menshi ya SiC yo gukura yibanda ku kongera ubushobozi bw'itanura. Ariko, aho kwagura gusa umusaruro, ni ngombwa cyane gusuzuma uburyo bwo kugabanya igihombo - cyane cyane mugihe umusaruro wikura rya kirisiti utaragera neza.

Ibikoresho byo gukata lazeri birashobora kugabanya cyane gutakaza ibikoresho no kongera umusaruro. Kurugero, ukoresheje mm 20 imweSiC ingot. Muri ibi bihe, ibyiza byo gukata lazeri biragaragara neza, bigatuma ikorana buhanga rya kazoza ka waferi-8.

Hamwe no gukata lazeri, igihe cyo gukata kuri wafer ya santimetero 8 gishobora kuba munsi yiminota 20, hamwe no gutakaza ibikoresho kuri wafer munsi ya 60 mm.

Muri make, ugereranije no guca insinga nyinshi, gukata lazeri bitanga umuvuduko mwinshi, umusaruro mwiza, gutakaza ibikoresho bike, no gutunganya neza.

Ikibazo: Ni izihe mbogamizi nyamukuru za tekinike mugukata lazeri ya SiC?

Igisubizo: Gukata lazeri bikubiyemo intambwe ebyiri zingenzi: guhindura laser no gutandukanya wafer.

Intandaro yo guhindura lazeri ni shitingi hamwe nibisobanuro byiza. Ibipimo nkimbaraga za laser, diameter yumwanya, hamwe na scan yihuta byose bigira ingaruka kumiterere yo gukuraho ibintu hamwe nubutsinzi bwo gutandukana kwa wafer. Uburinganire bwa zone yahinduwe bugena ubukana bwubuso ningorabahizi yo gutandukana. Ubuso buringaniye bugoye gusya nyuma kandi byongera gutakaza ibintu.

Nyuma yo guhinduka, gutandukana kwa wafer mubisanzwe bigerwaho hifashishijwe imbaraga zogosha, nko kuvunika gukonje cyangwa guhangayika. Sisitemu zimwe zo murugo zikoresha transducers ya ultrasonic kugirango itere kunyeganyega kugirango itandukane, ariko ibi birashobora gutera gukata no kunanirwa, bikagabanya umusaruro wanyuma.

Nubwo izi ntambwe zombi zitari zisanzwe zigoye, kudahuza ubuziranenge bwa kirisiti - bitewe nuburyo butandukanye bwo gukura, urwego rwa doping, hamwe no kugabana imihangayiko imbere - bigira ingaruka zikomeye zo kugabanya ingorane, umusaruro, no gutakaza ibintu. Kumenya gusa ibibazo byikibazo no guhindura laser scanning zone ntibishobora kunoza ibisubizo.

Urufunguzo rwo kwamamara kwinshi rushingiye mugutezimbere uburyo nibikoresho bishya bishobora guhuza nuburyo butandukanye bwimiterere ya kristu kuva mubakora inganda zitandukanye, guhuza ibipimo ngenderwaho, no kubaka sisitemu yo gukata lazeri hamwe nibisabwa kuri bose.

Ikibazo: Ese tekinoroji yo gukata laser irashobora gukoreshwa mubindi bikoresho bya semiconductor usibye SiC?

Igisubizo: Gukata Laser tekinoroji yakoreshejwe mumateka mugikoresho kinini. Muri semiconductor, yabanje gukoreshwa mugushushanya wafer kandi kuva yaguka kugeza gukata igice kinini cya kristu.

Kurenga SiC, gukata lazeri birashobora kandi gukoreshwa mubindi bikoresho bikomeye cyangwa byoroshye nka diyama, nitride ya gallium (GaN), na oxyde ya galiyo (Ga₂O₃). Ubushakashatsi bwibanze kuri ibi bikoresho bwerekanye uburyo nibyiza byo gukata lazeri kubice bya semiconductor.

Ikibazo: Muri iki gihe hari ibikoresho byo mu rugo bikuze byo gukata ibikoresho? Ni ikihe cyiciro ubushakashatsi bwawe burimo?

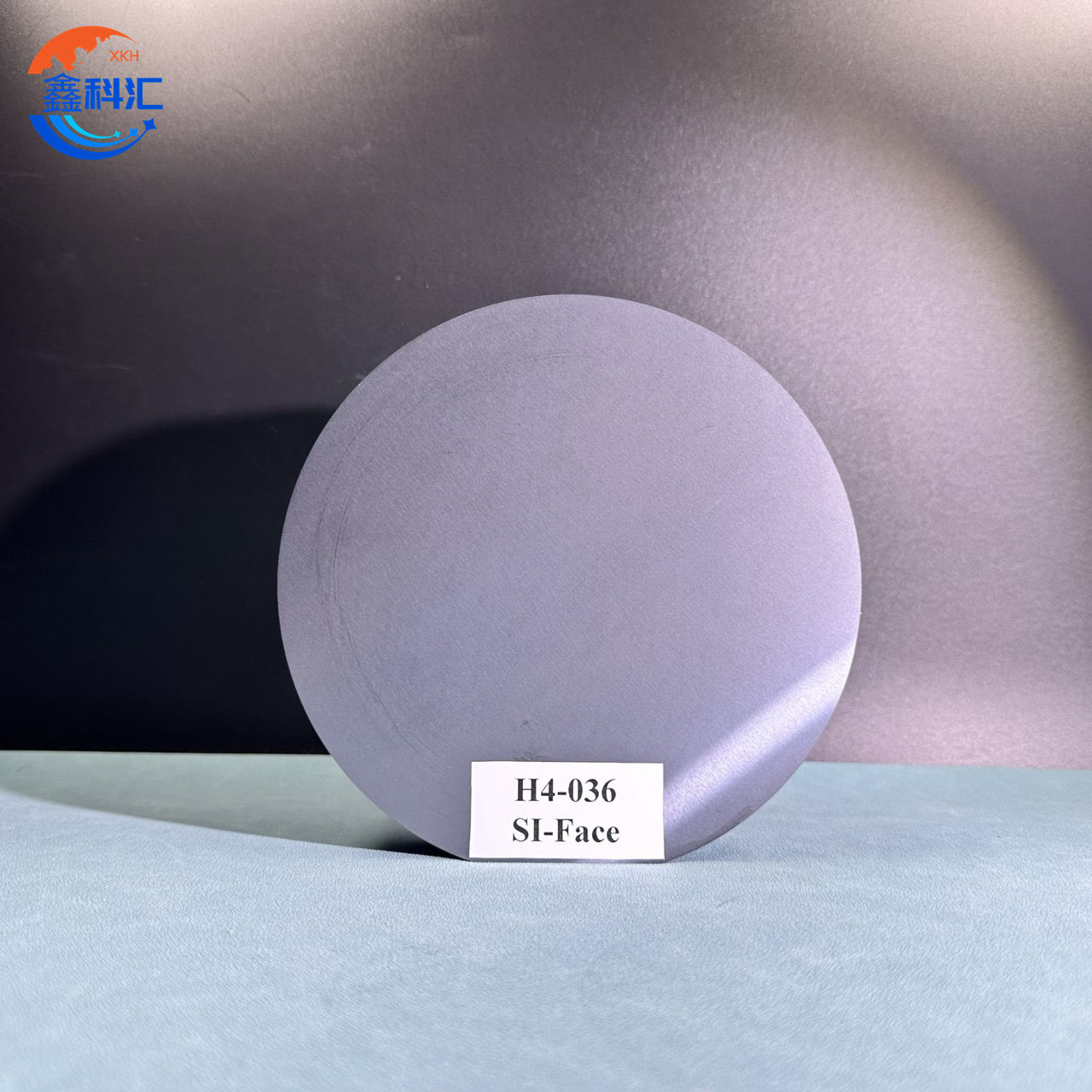

Igisubizo: Ibikoresho binini byo gutemagura SiC laser ya diametre bifatwa nkibikoresho byingenzi byigihe kizaza cyumusaruro wa wa-8 wa SiC. Kugeza ubu, Ubuyapani bwonyine ni bwo bushobora gutanga ubwo buryo, kandi buhenze kandi bugabanywa ibyoherezwa mu mahanga.

Ibikenerwa mu gihugu kuri sisitemu yo gukata / kunanura bivugwa ko bigera ku 1.000, hashingiwe kuri gahunda yo kubyaza umusaruro SiC n'ubushobozi bw'insinga zisanzwe. Ibigo bikomeye byo mu gihugu byashora imari cyane mu iterambere, ariko nta bikoresho bikuze, biboneka mu bucuruzi biboneka mu nganda.

Amatsinda yubushakashatsi yateje imbere tekinoroji ya laser yo kuzamura kuva 2001 kandi ubu yongereye ibi kugeza kuri diameter nini ya SiC laser gukata no kunanuka. Bateguye sisitemu ya prototype hamwe no gukata inzira ishoboye: Gukata no kunanura ibice bya santimetero 4-6 bya santimetero ya SiCIgukata ibice 6-8 bya santimetero ya SiC ingotsIbipimo ngenderwaho: Ibice 6-8 bya santimetero imwe ya SiC: gukata iminota 10-15 / wafer; gutakaza ibikoresho <30 μ m6-8 santimetero itwara SiC: gukata iminota 14-20 / wafer; gutakaza ibikoresho <60 mm

Ikigereranyo cy'umusaruro wafer wiyongereyeho hejuru ya 50%

Nyuma yo gukata, wafer yujuje ubuziranenge bwigihugu kuri geometrie nyuma yo gusya no gusya. Ubushakashatsi bwerekana kandi ko ingaruka ziterwa nubushyuhe bwa laser zidafite ingaruka zikomeye kumaganya cyangwa geometrie muri wafers.

Ibikoresho bimwe byanakoreshejwe kugirango hamenyekane niba bishoboka gukata diyama, GaN, na Ga₂O₃ kristu imwe.

Igihe cyo kohereza: Gicurasi-23-2025