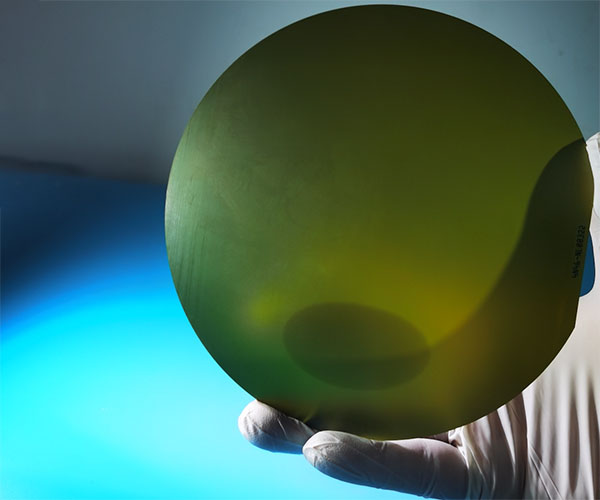

Kugeza ubu, isosiyete yacu irashobora gukomeza gutanga icyiciro gito cya 8inchN yo mu bwoko bwa SiC wafers, niba ufite icyitegererezo gikenewe, nyamuneka umbaze. Dufite ibyitegererezo by'icyitegererezo twiteguye kohereza.

Mu rwego rwibikoresho bya semiconductor, isosiyete imaze gutera intambwe nini mubushakashatsi no guteza imbere kristu nini ya SiC. Mugukoresha imbuto zayo bwite nyuma yo kwaguka kwinshi kwa diametre, isosiyete imaze gukura neza ya santimetero 8 zo mu bwoko bwa NC ya SiC, ikemura ibibazo bitoroshye nkumurima wubushyuhe butaringaniye, kumenagura kristu hamwe na gaz icyiciro cyibikoresho bikwirakwizwa mugikorwa cyo gukura kwa kirisiti ya SIC ya santimetero 8, kandi byihutisha iterambere ryikinini kinini cya SIC hamwe n’ikoranabuhanga ryigenga kandi ryigenga. Kuzamura cyane uruganda rwibanze mu guhatanira amasoko ya SiC imwe ya kristal substrate inganda. Muri icyo gihe, isosiyete iteza imbere cyane ikusanyamakuru ry’ikoranabuhanga hamwe n’uburyo bunini bwa silicon carbide substrate yo gutegura umurongo w’igeragezwa, ishimangira guhanahana tekinike n’ubufatanye mu nganda mu masoko yo mu majyepfo no mu majyepfo, kandi igafatanya n’abakiriya guhora basubiramo imikorere y’ibicuruzwa, kandi bigateza imbere umuvuduko wo gukoresha inganda za karibide.

| 8inch N-Ubwoko bwa SiC DSP | |||||

| Umubare | Ingingo | Igice | Umusaruro | Ubushakashatsi | Dummy |

| 1. Ibipimo | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | Icyerekezo | ° | <11-20> 4 ± 0.5 | <11-20> 4 ± 0.5 | <11-20> 4 ± 0.5 |

| 2. Ibikoresho by'amashanyarazi | |||||

| 2.1 | dopant | -- | Ubwoko bwa Azote | Ubwoko bwa Azote | Ubwoko bwa Azote |

| 2.2 | Kurwanya | ohm · cm | 0.015 ~ 0.025 | 0.01 ~ 0.03 | NA |

| 3. Ibikoresho bya mashini | |||||

| 3.1 | diameter | mm | 200 ± 0.2 | 200 ± 0.2 | 200 ± 0.2 |

| 3.2 | ubunini | μm | 500 ± 25 | 500 ± 25 | 500 ± 25 |

| 3.3 | Icyerekezo | ° | [1- 100] ± 5 | [1- 100] ± 5 | [1- 100] ± 5 |

| 3.4 | Uburebure bwimbitse | mm | 1 ~ 1.5 | 1 ~ 1.5 | 1 ~ 1.5 |

| 3.5 | LTV | μm | ≤5 (10mm * 10mm) | ≤5 (10mm * 10mm) | ≤10 (10mm * 10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Umuheto | μm | -25 ~ 25 | -45 ~ 45 | -65 ~ 65 |

| 3.8 | Intambara | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Imiterere | |||||

| 4.1 | Ubucucike bwa micropipe | ea / cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | ibyuma | atom / cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ea / cm2 | 00500 | 0001000 | NA |

| 4.4 | BPD | ea / cm2 | 0002000 | 0005000 | NA |

| 4.5 | TED | ea / cm2 | 0007000 | 0010000 | NA |

| 5. Ubwiza bwiza | |||||

| 5.1 | imbere | -- | Si | Si | Si |

| 5.2 | Kurangiza | -- | Si-face CMP | Si-face CMP | Si-face CMP |

| 5.3 | agace | ea / wafer | ≤100 (ubunini≥0.3μm) | NA | NA |

| 5.4 | gushushanya | ea / wafer | ≤5, Uburebure bwose200mm | NA | NA |

| 5.5 | Impande chips / indents / ibice / ikizinga / kwanduza | -- | Nta na kimwe | Nta na kimwe | NA |

| 5.6 | Agace ka polytype | -- | Nta na kimwe | Ubuso ≤10% | Ubuso ≤30% |

| 5.7 | Ikimenyetso cy'imbere | -- | Nta na kimwe | Nta na kimwe | Nta na kimwe |

| 6. Ubwiza bwinyuma | |||||

| 6.1 | inyuma kurangiza | -- | Umudepite | Umudepite | Umudepite |

| 6.2 | gushushanya | mm | NA | NA | NA |

| 6.3 | Inyuma yinyuma chip / indents | -- | Nta na kimwe | Nta na kimwe | NA |

| 6.4 | Inyuma yinyuma | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Ikimenyetso cyinyuma | -- | Ikimenyetso | Ikimenyetso | Ikimenyetso |

| 7. Impande | |||||

| 7.1 | inkombe | -- | Chamfer | Chamfer | Chamfer |

| 8. Ipaki | |||||

| 8.1 | gupakira | -- | Epi-yiteguye hamwe na vacuum gupakira | Epi-yiteguye hamwe na vacuum gupakira | Epi-yiteguye hamwe na vacuum gupakira |

| 8.2 | gupakira | -- | Multi-wafer gupakira | Multi-wafer gupakira | Multi-wafer gupakira |

Igihe cyo kohereza: Apr-18-2023