Nkibisekuru bya gatatu semiconductor substrate material,silicon karbide (SiC)kristu imwe ifite ibyerekezo byinshi byo gukoresha mugukora ibikoresho byinshi bya elegitoroniki. Tekinoroji yo gutunganya SiC igira uruhare runini mugukora ibikoresho byujuje ubuziranenge. Iyi ngingo iragaragaza uko ubushakashatsi bugezweho kuri tekinoroji yo gutunganya SiC haba mu Bushinwa ndetse no mu mahanga, gusesengura no kugereranya uburyo bwo guca, gusya, no gusya, hamwe n’ibigenda bigenda neza. Irerekana kandi imbogamizi zihari mugutunganya wafer wa SiC ikanaganira ku cyerekezo cyiterambere kizaza.

Carbide ya Silicon (SiC)wafers nibikoresho byingenzi byibanze kubikoresho bya semiconductor yo mu gisekuru cya gatatu kandi bifite akamaro gakomeye nubushobozi bwisoko mubice nka microelectronics, electronics electronique, no kumurika igice cya kabiri. Bitewe nuburemere bukabije cyane hamwe nubushakashatsi bwimiti yaSiC imwe, uburyo bwo gutunganya igice cya semiconductor ntabwo bukwiye rwose kubutunganya. Nubwo amasosiyete mpuzamahanga menshi yakoze ubushakashatsi bwimbitse kubijyanye no gutunganya tekinoroji ya sisitemu imwe ya SiC, tekinoroji ijyanye n’ibanga.

Mu myaka yashize, Ubushinwa bwongereye imbaraga mu iterambere ry’ibikoresho bya sisitemu imwe ya SiC. Nyamara, iterambere ry’ikoranabuhanga rya SiC mu gihugu muri iki gihe rihagarikwa n’imbogamizi mu ikoranabuhanga ritunganya ndetse n’ubuziranenge bwa wafer. Niyo mpamvu, ari ngombwa ko Ubushinwa butezimbere ubushobozi bwo gutunganya SiC kugirango buzamure ubwiza bwa SiC imwe rukumbi ya kristu kandi bugere ku bikorwa bifatika ndetse n’umusaruro rusange.

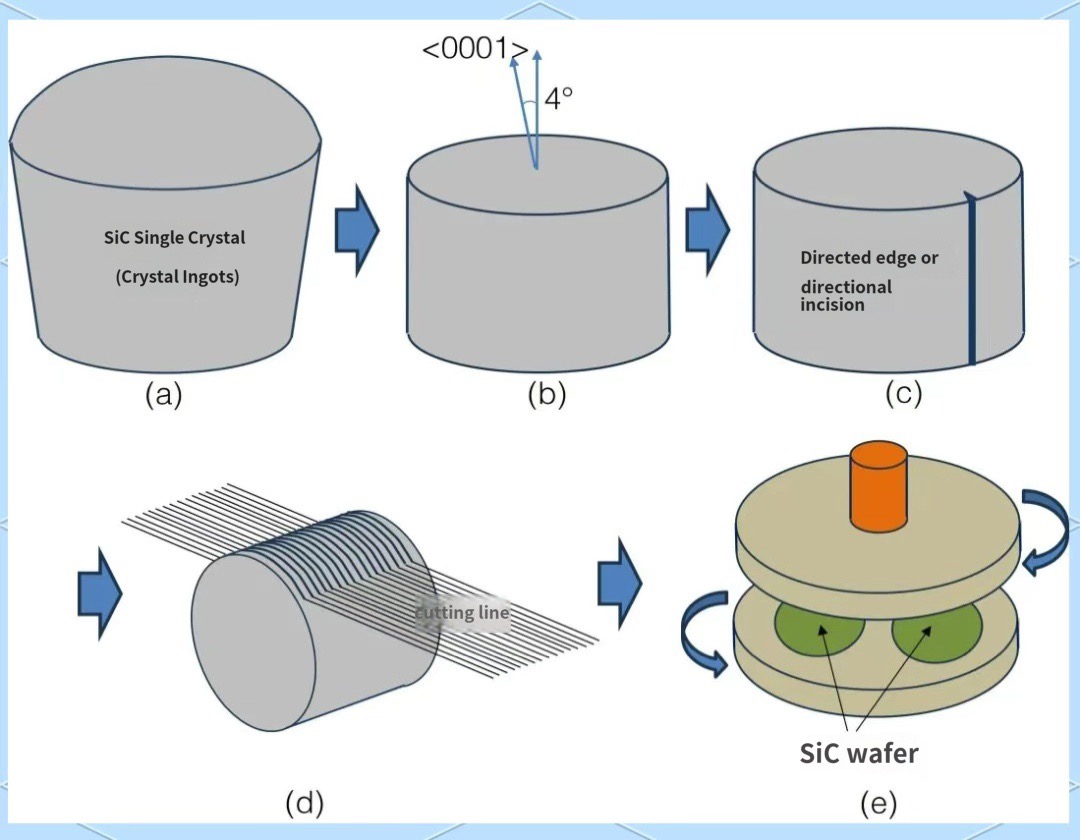

Intambwe zingenzi zo gutunganya zirimo: gukata → gusya gukabije → gusya neza → gusya neza (gukanika imashini) → gusya neza (gutunganya imashini, CMP) → kugenzura.

| Intambwe | Gutunganya Wafer | Gakondo ya Semiconductor imwe-Crystal ibikoresho byo gutunganya |

| Gukata | Koresha tekinoroji yo kubona ibyuma byinshi kugirango ugabanye ibikoresho bya SiC muri wafers yoroheje | Mubisanzwe ukoresha imbere-diameter cyangwa hanze-diameter tekinike yo gukata |

| Gusya | Igabanyijemo ibice kandi bisya neza kugirango ukureho ibimenyetso byangiritse kandi byangiritse byatewe no gukata | Uburyo bwo gusya bushobora gutandukana, ariko intego ni imwe |

| Kuringaniza | Harimo gukonjesha bikabije na ultra-precision ukoresheje imashini ya mashini na chimique (CMP) | Mubisanzwe harimo imashini yimashini (CMP), nubwo intambwe zihariye zishobora gutandukana |

Gukata SiC Crystal imwe

Mu gutunganyaSiC imwe, gukata nintambwe yambere kandi ikomeye cyane. Umuheto wa wafer, urufunzo, hamwe nubunini bwuzuye (TTV) biva muburyo bwo gutema bigena ubwiza nuburyo bwiza bwibikorwa byo gusya no gusya.

Ibikoresho byo gutema birashobora gutondekwa muburyo bwa diamant imbere ya diamant (ID), diameter yo hanze (OD), ibiti byuma, hamwe ninsinga. Ibyuma by'insinga, na byo, birashobora gushyirwa muburyo bwimikorere yabyo muburyo bwo gusubiranamo no kuzunguruka (bitagira iherezo). Ukurikije uburyo bwo guca ibintu byangiza, insinga zo gutema insinga zirashobora kugabanywamo ubwoko bubiri: kubona insinga zubusa no kubona insinga ya diyama.

1.1 Uburyo bwo gutema gakondo

Gukata ubujyakuzimu bwa diameter yo hanze (OD) ibiti bigarukira kuri diameter ya blade. Mugihe cyo gutema, icyuma gikunda kunyeganyega no gutandukana, bikaviramo urusaku rwinshi no gukomera gukabije. Imbere ya diametre (ID) ibiti bikoresha diyama kumuzenguruko wimbere wicyuma nkigice cyo guca. Ibyo byuma birashobora kuba binini nka mm 0.2. Mugihe cyo gukata, icyuma ndangamuntu kizunguruka ku muvuduko mwinshi mugihe ibikoresho bigomba gutemwa bigenda mu buryo bugereranije ugereranije n’icyuma, bikagera no gukata binyuze muri iki cyerekezo.

Ibiti bya diyama bisaba guhagarara kenshi no guhindukira, kandi umuvuduko wo kugabanya ni muto cyane - mubisanzwe ntabwo urenga 2 m / s. Bababazwa kandi no gukanika imashini hamwe nigiciro kinini cyo kubungabunga. Bitewe n'ubugari bw'icyuma kibonye, radiyo yo gukata ntishobora kuba nto cyane, kandi gukata ibice byinshi ntibishoboka. Ibi bikoresho gakondo byo gukata bigarukira ku gukomera kwifatizo kandi ntibishobora kugabanya gukata cyangwa kugabanya radiyo. Bashoboye gusa gukata neza, kubyara kerf nini, bifite umusaruro muke, bityo ntibikwiriye gukataKirisiti ya SiC.

1.2 Ubuntu Abrasive Wire Yabonye Gukata Multi-Wire

Umugozi wubusa wubusa wabonye tekinike yo gukata ikoresha kugenda byihuse byinsinga kugirango itwarwe muri kerf, ituma ibintu bivanwaho. Ikoresha cyane cyane imiterere yo kwisubiraho kandi kuri ubu ni uburyo bukuze kandi bukoreshwa cyane mugukata neza-wafer gukata silikoni imwe. Ariko, ikoreshwa ryayo mugukata SiC ntabwo ryizwe cyane.

Amashanyarazi yubusa yubusa arashobora gutunganya wafer ifite umubyimba uri munsi ya 300 mm. Zitanga igihombo gito, gake gitera gukata, kandi bivamo ubwiza bwubuso bwiza. Ariko, kubera uburyo bwo kuvanaho ibintu-bushingiye ku kuzunguruka no kwerekana ibyangiritse - ubuso bwa wafer bukunda gutera imbaraga zikomeye zisigaye, microcrake, hamwe n’ibyangiritse byimbitse. Ibi biganisha kuri wafer warping, bituma bigora kugenzura neza imiterere yubuso bwuzuye, kandi byongera umutwaro kumuntambwe ikurikira.

Imikorere yo gukata yatewe cyane no gusebanya; ni nkenerwa kugumana ubukana bwa abrasives hamwe nubunini bwa slurry. Kuvura bidatinze no gutunganya ibicuruzwa birahenze. Iyo ukata ingero nini nini, abrasives zifite ikibazo cyo kwinjira muri kerf ndende kandi ndende. Munsi yubunini bumwe bwimbuto, igihombo cya kerf kiruta icy'icyuma cyimeza.

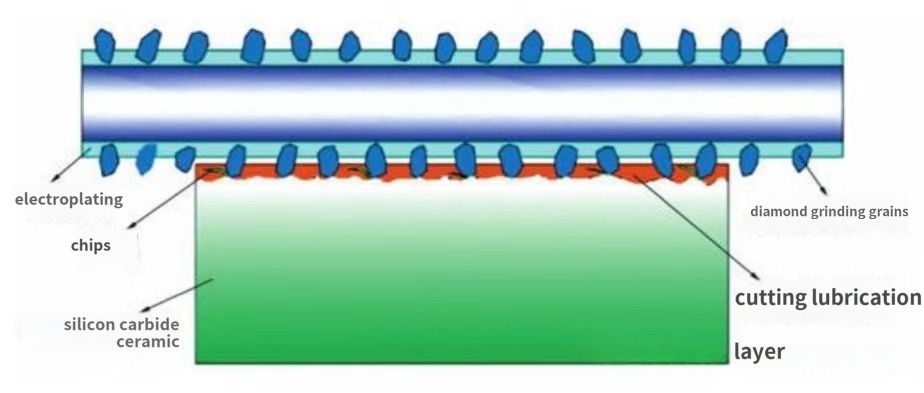

1.3 Umuyoboro wa Abrasive Diamond Ware wabonye Gukata Multi-Wire

Urusenda rwa diyama rukomeye rusanzwe rukozwe mugushira uduce duto twa diyama kumurongo wicyuma ukoresheje amashanyarazi, gucumura, cyangwa uburyo bwo guhuza resin. Amashanyarazi ya diyama ya elegitoronike atanga ibyiza nka kerfs ntoya, ubuziranenge bwibice, gukora neza, kwanduza hasi, hamwe nubushobozi bwo guca ibikoresho bikomeye.

Isubiranamo ryamashanyarazi ya diyama yabonye nuburyo bukoreshwa cyane mugukata SiC. Igishushanyo 1 (kiterekanwa hano) cyerekana ubuso bwa wafers ya SiC yaciwe ukoresheje ubu buhanga. Mugihe gukata bitera imbere, wafer warpage iriyongera. Ni ukubera ko aho uhurira hagati yinsinga nibikoresho byiyongera uko insinga igenda hepfo, ikongerera imbaraga hamwe no kunyeganyega. Iyo insinga igeze kuri diameter ntarengwa ya wafer, kunyeganyega biri hejuru, bikavamo intambara nini.

Mubyiciro byanyuma byo gutema, kubera insinga irimo kwihuta, kugenda-umuvuduko wihuse, kwihuta, guhagarara, no guhindukira, hamwe ningorane zo gukuraho imyanda hamwe na coolant, ubwiza bwubuso bwa wafer burangirika. Guhindura insinga no guhindagurika kwihuta, kimwe na diyama nini nini kuri wire, nizo mpamvu nyamukuru zitera gushushanya hejuru.

1.4 Ikoranabuhanga ryo Gutandukanya Ubukonje

Gutandukanya ubukonje bwa SiC kristu imwe nuburyo bushya muburyo bwo gutunganya ibikoresho bya semiconductor ya gatatu. Mu myaka yashize, yakunze kwitabwaho cyane kubera ibyiza byayo mu kuzamura umusaruro no kugabanya igihombo cyibintu. Ikoranabuhanga rishobora gusesengurwa uhereye kubintu bitatu: ihame ryakazi, imigendekere yimikorere, nibyiza byingenzi.

Icyerekezo cya Crystal Icyerekezo hamwe no gusya Diameter yo hanze: Mbere yo gutunganya, icyerekezo cya kirisiti ya SiC ingot igomba kugenwa. Ingot noneho ikorwa muburyo bwa silindrike (bakunze kwita SiC puck) ikoresheje gusya diameter yo hanze. Iyi ntambwe ishyiraho urufatiro rwo gukata icyerekezo no gukata.

Gukata Multi-Wire: Ubu buryo bukoresha ibice byangiza bifatanije no guca insinga kugirango ucagagure ingot ya silindrike. Ariko, irababara cyane kubura kerf nibibazo byuburinganire.

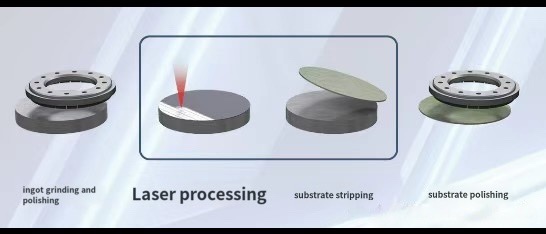

Ikoreshwa rya tekinoroji ya Laser: Lazeri ikoreshwa mugukora urwego rwahinduwe muri kristu, aho uduce duto duto dushobora gutandukana. Ubu buryo bugabanya igihombo cyibintu kandi byongera uburyo bwo gutunganya, bikagira icyerekezo gishya cyiza cyo gukata wafer wa SiC.

Gukata inzira

Gukata neza Abrasive Multi-Wire Gukata: Ubu ni tekinoroji yingenzi, ikwiranye nuburemere bukomeye buranga SiC.

Imashini isohora amashanyarazi (EDM) hamwe nubuhanga bwo gutandukanya ubukonje: Ubu buryo butanga ibisubizo bitandukanye bijyanye nibisabwa byihariye.

Igikorwa cyo gusya: Ni ngombwa kuringaniza igipimo cyo gukuraho ibintu no kwangirika hejuru. Imashini yimashini (CMP) ikoreshwa mugutezimbere ubuso.

Gukurikirana-Igihe nyacyo: Tekinoroji yo kugenzura kumurongo yatangijwe kugirango ikurikirane ubukana bwubutaka mugihe nyacyo.

Gukata Laser: Ubu buhanga bugabanya igihombo cya kerf kandi bigabanya uburyo bwo gutunganya, nubwo agace katewe nubushyuhe gakomeje kuba ingorabahizi.

Ikoreshwa rya tekinoroji ya Hybrid: Gukomatanya uburyo bwa mashini na chimique byongera imikorere neza.

Iri koranabuhanga rimaze kugera mubikorwa byinganda. Infineon, kurugero, yaguze SILTECTRA none ifite patenti yibanze zunganira umusaruro mwinshi wa waf-8. Mu Bushinwa, ibigo nka Delong Laser byageze ku musaruro wa wafer 30 kuri ingot yo gutunganya wafer ya santimetero 6, ibyo bikaba byerekana iterambere rya 40% muburyo gakondo.

Mugihe ibikoresho byo murugo byihuta, tekinoroji iteganijwe kuba igisubizo nyamukuru cyo gutunganya insimburangingo ya SiC. Hamwe na diameter yiyongera yibikoresho bya semiconductor, uburyo bwo guca gakondo bwarashaje. Muburyo bugezweho, gusubiranamo insinga ya diyama yabonye ikoranabuhanga ryerekana ibyifuzo byiringiro. Gukata Laser, nkubuhanga bugaragara, butanga ibyiza byingenzi kandi biteganijwe ko buzaba uburyo bwambere bwo guca mugihe kizaza.

2 、SiC imwe yo gusya

Nkumuhagarariye igice cya gatatu cya semiconductor, karbide ya silicon (SiC) itanga ibyiza byingenzi bitewe numuyoboro mugari, amashanyarazi menshi yamenetse, umuvuduko mwinshi wa electron drift umuvuduko, hamwe nubushyuhe bwiza bwumuriro. Iyi mitungo ituma SiC igira akamaro cyane mumashanyarazi menshi (urugero, 1200V ibidukikije). Tekinoroji yo gutunganya ibikoresho bya SiC nigice cyibanze cyo guhimba ibikoresho. Ubuso bwubuso nibisobanuro bya substrate bigira ingaruka kuburyo butaziguye ubwiza bwa epitaxial layer nigikorwa cyigikoresho cyanyuma.

Intego yibanze yo gusya ni ugukuraho ibimenyetso byerekanwe hejuru no kwangiza ibice byatewe mugihe cyo gukata, no gukosora deformasiyo iterwa no gutema. Urebye ubukana bwa SiC bukabije, gusya bisaba gukoresha imiti igabanya ubukana nka borb karbide cyangwa diyama. Gusya bisanzwe bisanzwe bigabanijwemo gusya neza no gusya neza.

2.1 Gusya neza no gusya neza

Gusya birashobora gutondekwa hashingiwe ku bunini bwa abrasive buke:

Gusya gukabije: Koresha ibinini binini cyane cyane kugirango ukureho ibimenyetso byangiritse no kwangiza ibice byatewe mugihe cyo gukata, kunoza imikorere.

Gusya neza: Koresha abrasives nziza kugirango ukureho ibyangiritse byasizwe no gusya nabi, kugabanya ububobere buke, no kuzamura ubwiza bwubuso.

Abenshi mu bakora uruganda rwa SiC substrate bakoresha uburyo bunini bwo gukora. Uburyo busanzwe burimo gusya impande zombi ukoresheje isahani yicyuma hamwe na diyama ya monocrystalline. Ubu buryo bukuraho neza ibyangiritse byasizwe no kubona insinga, bikosora imiterere ya wafer, kandi bigabanya TTV (Total Thickness Variation), Umuheto, na Warp. Igipimo cyo gukuraho ibintu kirahagaze, mubisanzwe kigera kuri 0.8-1.2 μ m / min. Nyamara, ubuso bwa wafer bwavuyemo ni matte hamwe nubusumbane bukabije - mubisanzwe hafi ya nm 50 - ibyo bikaba bisaba ibisabwa hejuru yintambwe zikurikira.

2.2 Gusya Kuruhande rumwe

Gusya kuruhande rumwe gusya inzira imwe gusa ya wafer icyarimwe. Muri iki gikorwa, wafer yashizwe mu gishashara ku isahani yicyuma. Munsi yigitutu gikoreshwa, substrate igenda ihinduka gato, kandi hejuru yo hejuru. Nyuma yo gusya, ubuso bwo hasi buringaniye. Iyo igitutu kivanyweho, ubuso bwo hejuru bukunda gusubira muburyo bwa mbere, nabwo bugira ingaruka kubutaka bumaze kuba hasi - bigatuma impande zombi zishongora kandi zikangirika muburinganire.

Byongeye kandi, isahani yo gusya irashobora guhinduka mugihe gito, bigatuma wafer ihinduka convex. Kugirango ugumane isahani, birasabwa kwambara kenshi. Bitewe nubushobozi buke hamwe nuburinganire bwa wafer bubi, gusya kuruhande rumwe ntibikwiye kubyara umusaruro mwinshi.

Mubisanzwe, # 8000 yo gusya ibiziga bikoreshwa mugusya neza. Mu Buyapani, iyi nzira irakuze kandi ikoresha # 30000 ibiziga. Ibi bituma uburinganire bwubuso bwa waferi yatunganijwe bugera munsi ya 2 nm, bigatuma wafer yitegura CMP yanyuma (Chemical Mechanical Polishing) nta gutunganya izindi.

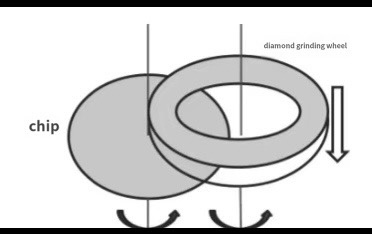

2.3 Ikoranabuhanga rimwe gusa

Diamond Umuyoboro umwe wo Kuringaniza Ubuhanga nuburyo bushya bwo gusya kuruhande rumwe. Nkuko bigaragara ku gishushanyo cya 5 (kiterekanwa hano), inzira ikoresha isahani isya ya diyama. Wafer ikosorwa binyuze muri vacuum adsorption, mugihe wafer hamwe nuruziga rwa diyama ruzunguruka icyarimwe. Uruziga rusya rugenda rwimuka rugana hasi kugirango rworohereze wafer kugera kuntego. Uruhande rumwe rumaze kuzuzwa, wafer ihindurwa kugirango itunganyirize kurundi ruhande.

Nyuma yo kunanuka, wafer ya mm 100 irashobora kugeraho:

Umuheto <5 mm

TTV <2 mm

Ubuso bwubuso <1 nm

Ubu buryo bumwe bwo gutunganya butanga ituze ryinshi, guhoraho, hamwe nigipimo kinini cyo gukuraho ibintu. Ugereranije no gusya kabiri-gusya, ubu buryo butezimbere gusya hejuru ya 50%.

2.4 Gusya Kabiri

Gusya impande zombi zikoresha isahani yo hejuru no hepfo yo gusya icyarimwe gusya icyarimwe gusya impande zombi za substrate, bigatuma ubuziranenge bwubuso bwiza kumpande zombi.

Mugihe cyibikorwa, gusya amasahani banza ushyireho igitutu kumurongo wo hejuru wakazi, bigatera guhindagurika no gukuraho ibintu buhoro buhoro kuri izo ngingo. Mugihe ibibanza birebire bingana, umuvuduko kuri substrate ugenda uhinduka umwe, bikavamo guhinduka guhoraho hejuru yubutaka bwose. Ibi bituma hejuru no hejuru hejuru yubutaka buringaniye. Iyo gusya bimaze kurangira hamwe nigitutu kirekuwe, buri gice cya substrate gisubirana kimwe kubera igitutu kingana nacyo. Ibi biganisha ku ntambara ntoya no kuringaniza neza.

Ubuso bwubuso bwa wafer nyuma yo gusya biterwa nubunini bwa abrasive - uduce duto dutanga ubuso bworoshye. Iyo ukoresheje 5 μm abrasives kugirango usya impande ebyiri, uburinganire bwa wafer hamwe nubunini bwabyo birashobora kugenzurwa muri 5 mm. Ibipimo bya Atomic Force Microscopy (AFM) byerekana uburinganire bwubuso (Rq) bwa metero 100 nm, hamwe nibyobo byo gusya bigera kuri 380 nm byimbitse kandi bigaragara kumurongo ugaragara uterwa nigikorwa cyo gutukana.

Uburyo bwateye imbere burimo gusya impande ebyiri ukoresheje polyurethane ifuro yamashanyarazi hamwe na polycrystalline diamant slurry. Ubu buryo butanga waferi hamwe nubuso buke cyane, bugera kuri Ra <3 nm, ifitiye akamaro kanini gukurikiraho kwa SiC substrates.

Ariko, gushushanya hejuru biracyari ikibazo kidakemutse. Byongeye kandi, diyama ya polycrystalline ikoreshwa muriki gikorwa ikorwa hakoreshejwe synthesis iturika, igoye tekinike, itanga umusaruro muke, kandi ihenze cyane.

Kuringaniza SiC Crystal imwe

Kugirango ugere ku buso buhanitse bwogejwe hejuru ya waferi ya silicon karbide (SiC), gusya bigomba gukuraho burundu ibyobo byo gusya hamwe nuburinganire bwa nanometero. Intego nugukora ubuso butagira inenge, butagira inenge nta kwanduza cyangwa kwangirika, nta kwangirika kwubutaka, nta guhangayikishwa nubutaka busigaye.

3.1 Gukora imashini na CMP ya SiC Wafers

Nyuma yo gukura kwa SiC imwe ya kirisiti ya kirisiti, inenge zo hejuru zirinda gukoreshwa muburyo butaziguye bwo gukura. Kubwibyo, birakenewe gutunganywa. Ingot yabanje kubumbwa muburyo busanzwe bwa silindrike binyuze muruziga, hanyuma igabanywa muri wafer ukoresheje gukata insinga, hanyuma hagakurikiraho kugenzura icyerekezo cya kristu. Polishingi nintambwe yingenzi mugutezimbere ubuziranenge bwa wafer, gukemura ibyangiritse byatewe nubusembwa bwikura rya kirisiti hamwe nintambwe yo gutunganya mbere.

Hariho uburyo bune bwingenzi bwo gukuraho ibyangiritse hejuru kuri SiC:

Gukanika imashini: Byoroshye ariko bisiga ibishushanyo; bikwiranye no gusya bwa mbere.

Imashini ya mashini (CMP): Ikuraho ibishushanyo ukoresheje imiti; bikwiranye neza.

Gutera hydrogène: Bisaba ibikoresho bigoye, bikunze gukoreshwa mubikorwa bya HTCVD.

Plasma ifashwa no gusya: Biragoye kandi ntibikoreshwa cyane.

Gukoresha imashini gusa bikunda gutera ibishishwa, mugihe imiti-yonyine ishobora gukurura ibishishwa bitaringaniye. CMP ikomatanya ibyiza byombi kandi itanga igisubizo cyiza, cyigiciro cyinshi.

Ihame ry'akazi rya CMP

CMP ikora mukuzunguruka wafer munsi yumuvuduko washyizweho na pisine izunguruka. Uku kugenda kugereranije, gufatanije no gukuramo imashini zivuye muri nano-nini ya abrasives muri slurry hamwe nigikorwa cyimiti yimiti ikora, igera kubutaka.

Ibikoresho by'ingenzi byakoreshejwe:

Polishing slurry: Harimo abrasives na reagent ya chimique.

Amashanyarazi: Yambara mugihe cyo gukoresha, kugabanya ingano ya pore no gutanga neza. Kwambara bisanzwe, mubisanzwe ukoresheje umwambaro wa diyama, birasabwa kugarura ububi.

Inzira ya CMP isanzwe

Abrasive: 0.5 μm diamant slurry

Intego yo hejuru igoye: ~ 0.7 nm

Amashanyarazi ya mashini:

Ibikoresho byo gusya: AP-810 icyuma kimwe

Umuvuduko: 200 g / cm²

Umuvuduko w'isahani: 50 rpm

Umuvuduko wa Ceramic: 38 rpm

Ibihimbano:

SiO₂ (30 wt%, pH = 10.15)

0-70 wt% H₂O₂ (30 wt%, urwego rwa reagent)

Hindura pH kuri 8.5 ukoresheje 5 wt% KOH na 1 wt% HNO₃

Igipimo cyihuta: 3 L / min, kizunguruka

Iyi nzira itezimbere neza ubuziranenge bwa SiC kandi yujuje ibisabwa mubikorwa byo hasi.

Inzitizi za tekinike muri Mechanical Polishing

SiC, nkigice kinini cya semiconductor, igira uruhare runini mubikorwa bya elegitoroniki. Hamwe nibintu byiza byumubiri nubumara, SiC imwe ya kristu ikwiranye nibidukikije bikabije, nkubushyuhe bwo hejuru, inshuro nyinshi, imbaraga nyinshi, hamwe n’imishwarara. Nyamara, imiterere yayo ikomeye kandi yoroheje iragaragaza ibibazo bikomeye byo gusya no gusya.

Nkuko abakora inganda zikomeye ku isi bava kuri santimetero 6 bakajya kuri waferi 8, ibibazo nko guturika no kwangirika kwa wafer mugihe cyo gutunganya byagaragaye cyane, bigira ingaruka cyane ku musaruro. Gukemura ibibazo bya tekinike ya santimetero 8 za SiC substrate ubu ni igipimo cyingenzi cyiterambere ryinganda.

Mugihe cya santimetero 8, gutunganya wafer ya SiC ihura nibibazo byinshi:

Igipimo cya Wafer kirakenewe kugirango umusaruro wa chip wiyongere kuri buri cyiciro, kugabanya igihombo, hamwe nigiciro cyumusaruro - cyane cyane bitewe nubwiyongere bwibisabwa mumashanyarazi.

Mugihe imikurire ya santimetero 8 za SiC imwe ya kristu imaze gukura, inzira yinyuma nko gusya no gusya iracyafite imbogamizi, bikavamo umusaruro muke (40-50% gusa).

Wafers nini ifite uburambe bwo gukwirakwiza igitutu, byongera ingorane zo gukemura ibibazo bya polishinge no gutanga umusaruro.

Nubwo umubyimba wa waferi 8-wegereje ugera kuri waferi ya santimetero 6, usanga bikunze kwangirika mugihe cyo gukemura bitewe no guhangayika no kurwana.

Kugabanya kugabanuka guterwa no guhagarika umutima, kurupapuro, no guturika, gukata lazeri birakoreshwa cyane. Icyakora:

Laser ndende-ndende itera kwangirika kwubushyuhe.

Lazeri ngufi-yumubyimba itanga imyanda iremereye kandi ikanagura ibyangiritse, byongera polishinge.

Imashini ya Polishike Yakazi ya SiC

Inzira rusange igenda ikubiyemo:

Gukata icyerekezo

Gusya nabi

Gusya neza

Gukoresha imashini

Imashini yimashini (CMP) nkintambwe yanyuma

Guhitamo uburyo bwa CMP, gutunganya inzira, no gutezimbere ibipimo nibyingenzi. Mu gukora semiconductor, CMP niyo ntambwe igena kubyara waferi ya SiC ifite ultra-yoroshye, idafite inenge, kandi nta byangiritse, bifite akamaro kanini mu mikurire yo mu rwego rwo hejuru.

(a) Kuraho ingot ya SiC mubikomeye;

(b) Kora shapure yambere ukoresheje gusya diameter yo hanze;

(c) Menya icyerekezo cya kirisiti ukoresheje igorofa cyangwa igorofa;

(d) Kata ingot muri wafers yoroheje ukoresheje insinga nyinshi;

(e) Kugera ku ndorerwamo imeze nk'ubuso bworoshye binyuze mu gusya no gusya intambwe.

Nyuma yo kurangiza urukurikirane rwintambwe yo gutunganya, inkombe yinyuma ya SiC wafer akenshi iba ityaye, ibyo bikaba byongera ibyago byo gukata mugihe cyo gukora cyangwa gukoresha. Kugirango wirinde gucika intege, gusya kuruhande birasabwa.

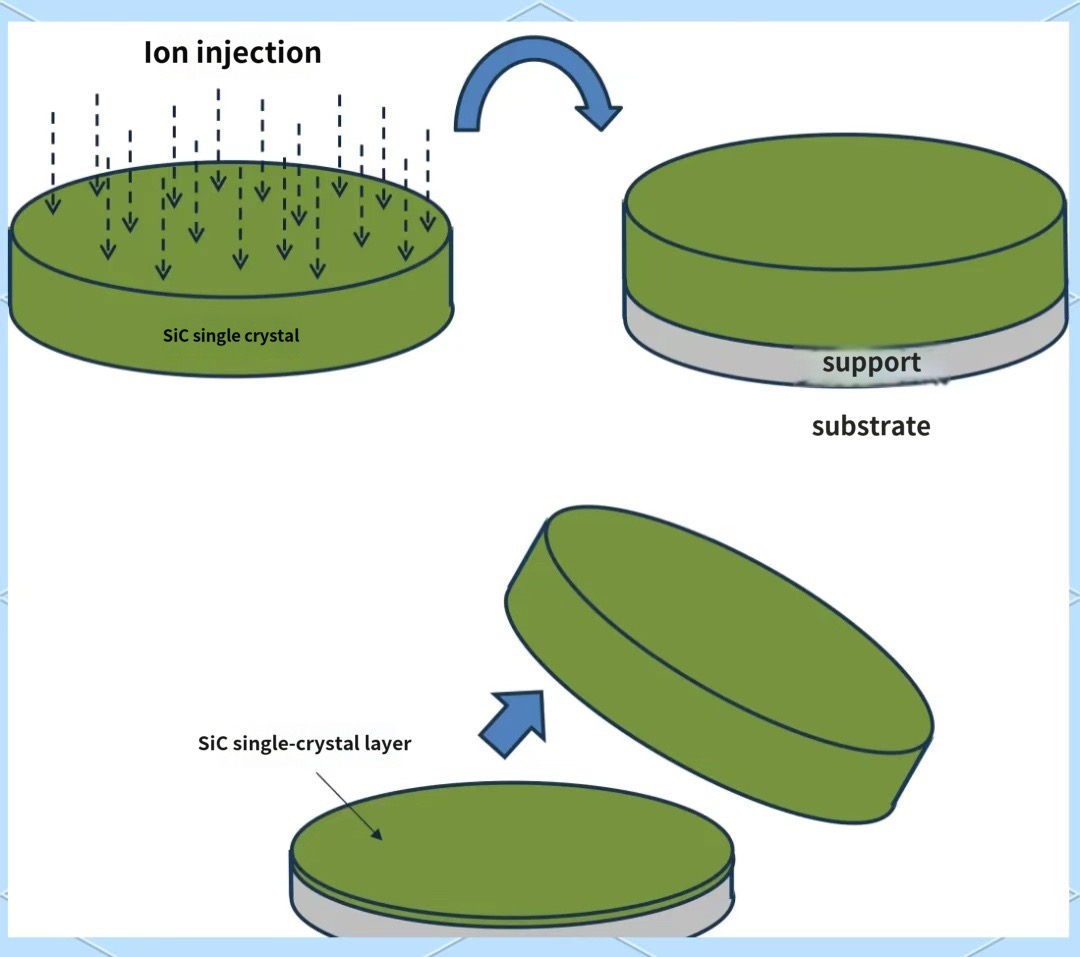

Usibye uburyo bwo gutema gakondo, uburyo bushya bwo gutegura waferi ya SiC harimo guhuza ikoranabuhanga. Ubu buryo butuma ibihimbano bya wafer bihuza urwego ruto rwa SiC rukuruzi ya kirisiti hamwe na heterogeneous substrate (substrate substrate).

Igishushanyo cya 3 cyerekana inzira igenda:

Ubwa mbere, urwego rwo gusiba rwakozwe mubwimbike bwihariye hejuru yubuso bwa SiC kristal imwe ikoresheje hydrogène ion yatewe cyangwa tekiniki zisa. Ikoreshwa rya SiC imwe yatunganijwe noneho ihujwe na substrate ishigikira kandi ikorerwa igitutu nubushyuhe. Ibi bituma ihererekanyabubasha nogutandukanya SiC imwe-kristaliste kumurongo ushyigikira substrate.

Igice cya SiC gitandukanijwe kivurwa hejuru kugirango kigere kuburinganire busabwa kandi gishobora kongera gukoreshwa muburyo bwo guhuza. Ugereranije no gukata gakondo ya kristu ya SiC, ubu buhanga bugabanya gukenera ibikoresho bihenze. Nubwo ibibazo bya tekiniki bikiriho, ubushakashatsi niterambere biratera imbere cyane kugirango umusaruro wafer uhendutse.

Urebye ubukana bwinshi n’imiti ihamye ya SiC-ituma idashobora guhangana n’ubushyuhe bw’icyumba - isuku ya mashini irasabwa gukuraho ibyobo byiza byo gusya, kugabanya ibyangiritse hejuru, gukuraho ibishishwa, gutobora, hamwe n’ibishishwa by’ibishishwa bya orange, ububobere buke bwo hejuru, kunoza uburinganire, no kuzamura ubwiza bw’ubutaka.

Kugirango ugere ku buso buhanitse bwo hejuru, ni ngombwa kuri:

Hindura ubwoko bubi,

Mugabanye ingano,

Hindura ibipimo ngenderwaho,

Hitamo ibikoresho byo gusya hamwe nudupapuro hamwe nubukomezi buhagije.

Igicapo 7 kirerekana ko guswera impande zombi hamwe na 1 μm abrasives bishobora kugenzura uburinganire nuburinganire hagati ya 10 mm, kandi bikagabanya ubukana bwubuso bugera kuri 0,25 nm.

3.2 Amashanyarazi ya mashini (CMP)

Imashini ya mashini (CMP) ikomatanya gukuramo ultrafine nuduce twa chimique kugirango habeho ubuso bworoshye, buteganijwe ku bikoresho bitunganywa. Ihame shingiro ni:

Imiti yimiti ibaho hagati yo gusya no hejuru ya wafer, ikora urwego rworoshye.

Ubuvanganzo hagati yuduce duto duto kandi tworoheje dukuraho ibikoresho.

Ibyiza bya CMP:

Yatsinze ibibi byo gukanika imashini cyangwa imiti gusa,

Kugera ku isi yose no mu karere,

Bitanga ubuso hamwe nuburinganire buringaniye hamwe nubukonje buke,

Ntibisiga hejuru cyangwa kwangirika kwisi.

Mu magambo arambuye:

Wafer yimuka ugereranije na padi ya poling munsi yigitutu.

Ubunini bwa Nanometero (urugero, SiO₂) muburyo bwo kogosha bitabira kogoshesha, guca intege imiyoboro ya Si - C no kongera ibikoresho.

Ubwoko bwa tekinike ya CMP:

Ubusa Abrasive Polishing: Abrasives (urugero, SiO₂) zihagarikwa muburyo bworoshye. Gukuraho ibintu bibaho binyuze mumubiri itatu (wafer - pad - abrasive). Ingano ikabije (mubisanzwe 60-200 nm), pH, nubushyuhe bigomba kugenzurwa neza kugirango bitezimbere.

Gukuraho neza Abrasive Polishing: Abrasives zashyizwe mumashanyarazi kugirango birinde agglomeration - nibyiza gutunganywa neza.

Isuku nyuma yo gusukura:

Wafer isukuye:

Isuku yimiti (harimo amazi ya DI no gukuraho ibisigazwa bya slurry),

DI amazi yoza, kandi

Kuma azote ishyushye

kugabanya umwanda wanduye.

Ubuso Bwiza & Imikorere

Ubuso bwubuso burashobora kugabanuka kuri Ra <0.3 nm, byujuje ibyangombwa bya semiconductor ibisabwa.

Iterambere ry’isi yose: Gukomatanya koroshya imiti no kuvanaho imashini bigabanya gushushanya no guterana kutaringaniye, kurenza uburyo bwubukanishi cyangwa imiti.

Ubushobozi buhanitse: Bikwiranye nibikoresho bikomeye kandi byoroshye nka SiC, hamwe nigipimo cyo gukuraho ibikoresho kiri hejuru ya 200 nm / h.

Ubundi buryo bwa Emerging Polishing Technique

Usibye CMP, ubundi buryo bwasabwe, harimo:

Amashanyarazi yamashanyarazi, Catalyst-afashijwe guswera cyangwa kurigata, na

Amashanyarazi.

Nyamara, ubu buryo buracyari mubyiciro byubushakashatsi kandi bwateye imbere buhoro buhoro kubera ibintu bitoroshye bya SiC.

Ubwanyuma, gutunganya SiC ni inzira gahoro gahoro yo kugabanya intambara nuburangare kugirango tunoze ubwiza bwubuso, aho uburinganire no kugenzura bikabije muri buri cyiciro.

Ikoranabuhanga

Mugihe cyo gusya wafer, gusya kwa diyama nubunini butandukanye bikoreshwa mugusya wafer kumurongo usabwa hamwe no gukomera hejuru. Ibyo bikurikirwa no gusya, ukoresheje tekinike yubukanishi nubumashini (CMP) kugirango ubyare umusaruro wangiritse wa silicon karbide (SiC).

Nyuma yo gusya, wafer ya SiC ikorerwa igenzura rikomeye hifashishijwe ibikoresho nka microscopique optique na X-ray diffractometero kugirango ibipimo byose bya tekiniki byujuje ubuziranenge busabwa. Hanyuma, waferi isukuye isukurwa hifashishijwe ibikoresho byabugenewe byogusukura namazi ya ultrapure kugirango bikureho umwanda. Baca bakama bakoresheje gaze ya azote ya ultra-high isukuye hamwe na spin yumye, bikarangiza ibikorwa byose.

Nyuma yimyaka myinshi yimbaraga, intambwe igaragara imaze guterwa muri SiC imwe itunganya kristu mu Bushinwa. Imbere mu gihugu, mm 100 ya dope igice kimwe cya 4H-SiC kristu imwe yatunganijwe neza, kandi n-ubwoko bwa 4H-SiC na 6H-SiC kristu imwe irashobora gukorerwa mubice. Ibigo nka TankeBlue na TYST bimaze guteza imbere mm 150 ya SiC imwe ya kristu.

Kubijyanye na tekinoroji yo gutunganya SiC wafer, ibigo byimbere mu gihugu byabanje gushakisha uburyo inzira n'inzira zo gukata kristu, gusya, no gusya. Bashoboye gutanga ingero zujuje cyane cyane ibisabwa kugirango bahimbe ibikoresho. Ariko, ugereranije nubuziranenge mpuzamahanga, ubwiza bwo gutunganya hejuru ya wafer yo murugo buracyari inyuma cyane. Hariho ibibazo byinshi:

Amahanga mpuzamahanga ya SiC hamwe nikoranabuhanga ryo gutunganya birarinzwe cyane kandi ntibyoroshye kuboneka.

Hano harabura ubushakashatsi bwubushakashatsi ninkunga yo kunoza inzira no gutezimbere.

Igiciro cyo gutumiza ibikoresho byamahanga nibigize byinshi.

Ubushakashatsi bwo murugo kubushakashatsi bwibikoresho, gutunganya neza, nibikoresho biracyerekana icyuho gikomeye ugereranije ninzego mpuzamahanga.

Kugeza ubu, ibikoresho byinshi-bisobanutse neza bikoreshwa mu Bushinwa bitumizwa mu mahanga. Ibikoresho byo gupima nuburyo bukoreshwa nabyo bisaba kurushaho kunozwa.

Hamwe nogukomeza iterambere ryibisekuru byigisekuru cya gatatu, diameter ya SiC imwe ya kristal substrate igenda yiyongera gahoro gahoro, hamwe nibisabwa hejuru kugirango ubuziranenge butunganyirizwe. Tekinoroji yo gutunganya Wafer yabaye imwe muntambwe igoye nyuma ya SiC imwe yo gukura.

Kugira ngo dukemure ibibazo biriho mu gutunganya, ni ngombwa kurushaho kwiga uburyo bukoreshwa mu guca, gusya, no gusya, no gushakisha uburyo bukwiye n'inzira zikoreshwa mu gukora wafer wa SiC. Muri icyo gihe, birakenewe ko twigira ku buhanga bugezweho bwo gutunganya no gukoresha tekinoloji n’ibikoresho bigezweho bya ultra-precision tekinike yo gutunganya ibikoresho byo mu rwego rwo hejuru.

Mugihe ubunini bwa wafer bwiyongera, ingorane zo gukura kwa kristu no gutunganya nabyo biriyongera. Nyamara, imikorere yubukorikori bwibikoresho byo hasi iratera imbere kuburyo bugaragara, kandi igiciro cyigabanuka. Kugeza ubu, abatanga isoko rya SiC wafer ku isi yose batanga ibicuruzwa kuva kuri santimetero 4 kugeza kuri santimetero 6. Ibigo bikomeye nka Cree na II-VI byatangiye gutegura igenamigambi ryiterambere rya santimetero 8 za SiC wafer.

Igihe cyo kohereza: Gicurasi-23-2025