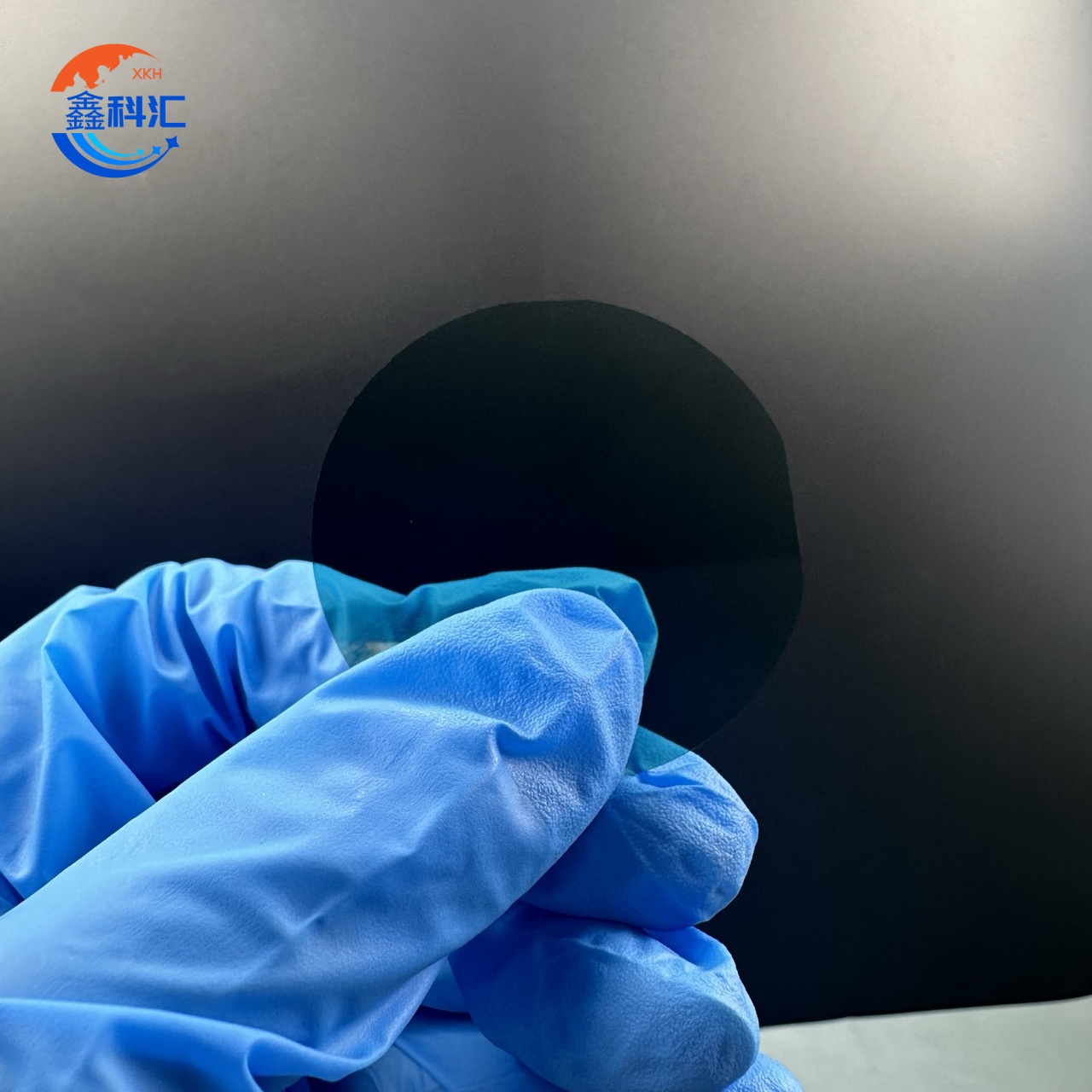

2inch silicon karbide substrate 6H-N impande ebyiri zometse kuri diameter 50.8mm icyiciro cyubushakashatsi

Ibikurikira nibiranga 2inch silicon karbide wafer:

1. Kurwanya imirasire myiza: Wafer ya SIC ifite imbaraga zo kurwanya imirasire ikomeye, bigatuma ikoreshwa muburyo bwimirasire. Ingero zirimo icyogajuru n'ibikoresho bya kirimbuzi.

2. Gukomera cyane: Wafer ya SIC irakomeye kuruta silikoni, yongerera igihe kirekire waferi mugihe cyo kuyitunganya.

3

4.

5. Ubucucike buri hejuru: Hamwe nibiranga hejuru, ibikoresho bya SIC wafer birashobora kugera kumasoko menshi murwego ruto.

2inch silicon karbide wafer ifite progaramu nyinshi.

1. Amashanyarazi ya elegitoronike: Wafers ya SiC ikoreshwa cyane mubikoresho bya elegitoroniki byamashanyarazi nka moteri ihindura amashanyarazi, inverter, hamwe n’amashanyarazi menshi bitewe n’umuvuduko mwinshi w’amashanyarazi hamwe n’ibiranga ingufu nke.

2. Imodoka zikoresha amashanyarazi: Wafer ya silicon karbide ikoreshwa mumashanyarazi yimodoka yamashanyarazi kugirango yongere imikorere kandi igabanye ibiro, bivamo kwishyurwa byihuse kandi intera ndende.

3.

4.Ijuru n’Ingabo: Wafers ya SiC ni ngombwa mu nganda zo mu kirere n’ingabo zirinda ubushyuhe bwinshi, ingufu nyinshi n’imirasire irwanya imirasire, harimo sisitemu y’indege na sisitemu ya radar.

ZMSH itanga ibicuruzwa byo kugurisha ibicuruzwa bya silicon karbide wafer. Wafers yacu ikozwe muburyo bwiza bwa silicon karbide yaturutse mubushinwa kugirango irambe kandi yizewe. Abakiriya barashobora guhitamo mubyo twahisemo ingano ya wafer nibisobanuro kugirango bahuze ibyo bakeneye.

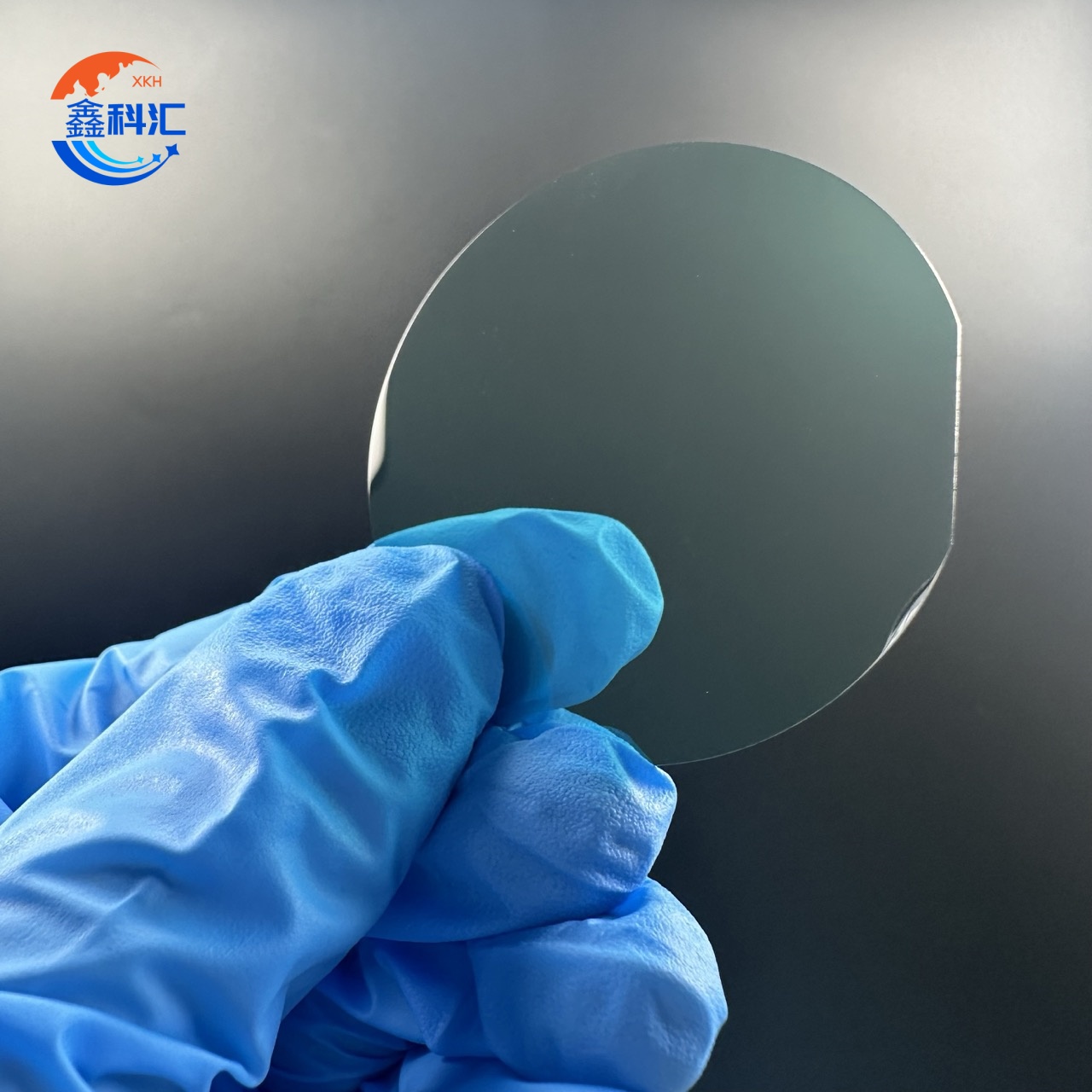

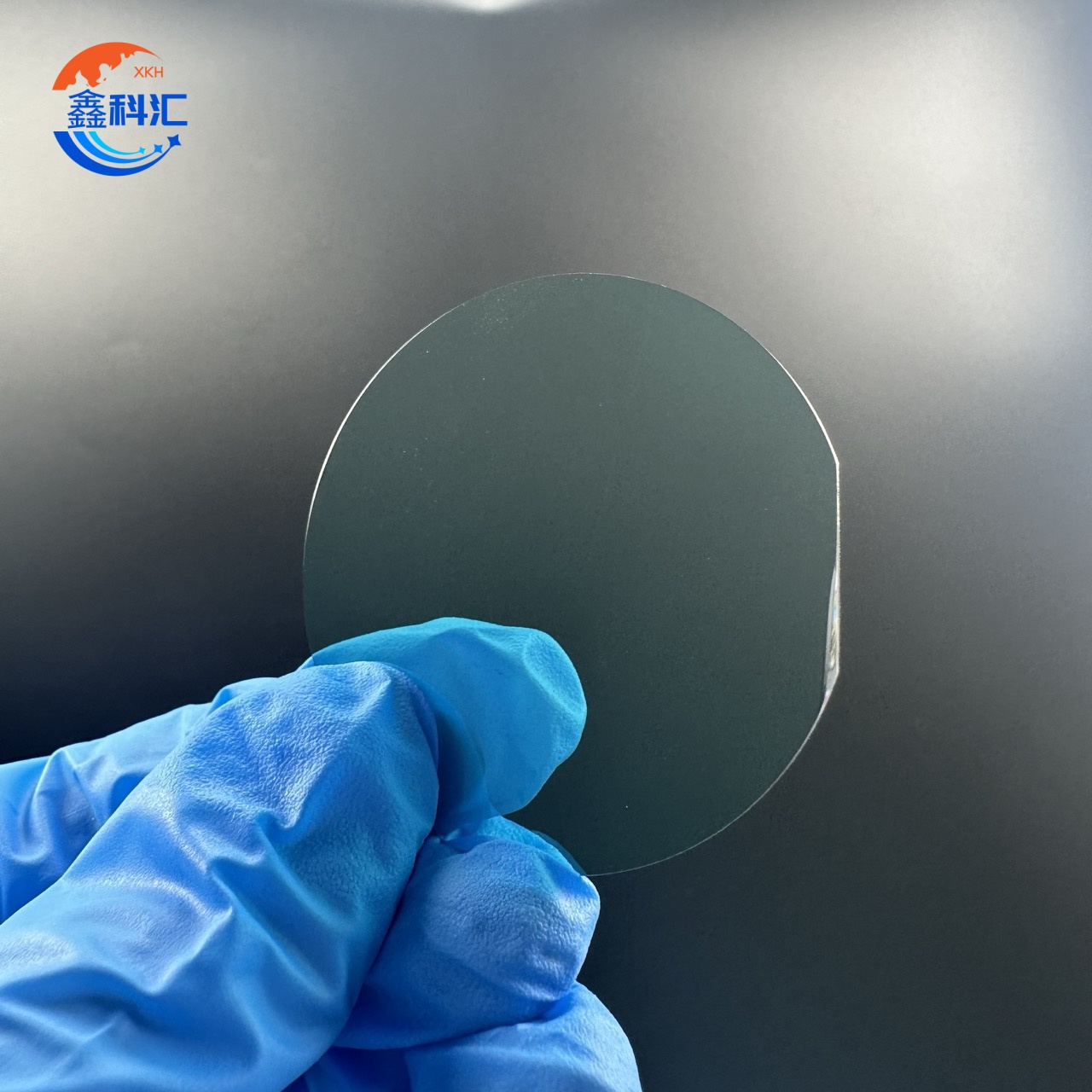

Wafers yacu ya Silicon Carbide ije muburyo butandukanye no mubunini, icyitegererezo ni Caricon Carbide.

Dutanga uburyo butandukanye bwo kuvura burimo uburinganire bumwe / bubiri buringaniye hamwe n'ubuso bukabije ≤1.2nm hamwe n'uburinganire Lambda / 10. Turatanga kandi amahitamo maremare / make yo kwihanganira ashobora gutegurwa kubyo usabwa. EPD yacu ya ≤1E10 / cm2 yemeza ko wafer yacu yujuje ubuziranenge bwinganda.

Duhangayikishijwe na buri kantu kose k'ipaki, isuku, anti-static, kuvura ihungabana .Dukurikije ubwinshi n'imiterere y'ibicuruzwa, tuzafata ubundi buryo bwo gupakira! Hafi ya kaseti imwe ya wafer cyangwa cassette ya 25pcs mucyumba cyogusukura 100.

Igishushanyo kirambuye