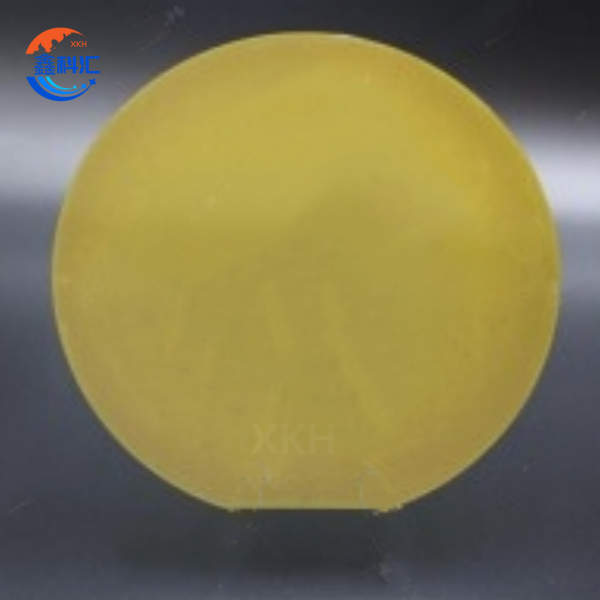

6 inch Imiyoboro imwe ya kristu ya SiC kuri polycrystalline SiC igizwe na substrate Diameter 150mm P ubwoko bwa N.

Ibipimo bya tekiniki

| Ingano: | 6 santimetero |

| Diameter: | Mm 150 |

| Umubyimba: | 400-500 mm |

| Monocrystalline SiC Ibipimo bya Filime | |

| Polytype: | 4H-SiC cyangwa 6H-SiC |

| Kwibanda kuri Doping: | 1 × 10¹⁴ - 1 × 10¹⁸ cm⁻³ |

| Umubyimba: | 5-20 mm |

| Impapuro zo Kurwanya: | 10-1000 Ω / sq |

| Imashini ya elegitoronike: | 800-1200 cm² / V. |

| Umuyoboro wa Hole: | 100-300 cm² / V. |

| Ibipimo bya Polycrystalline SiC Buffer | |

| Umubyimba: | 50-300 mm |

| Amashanyarazi: | 150-300 W / m · K. |

| Monocrystalline SiC Substrate Ibipimo | |

| Polytype: | 4H-SiC cyangwa 6H-SiC |

| Kwibanda kuri Doping: | 1 × 10¹⁴ - 1 × 10¹⁸ cm⁻³ |

| Umubyimba: | 300-500 mm |

| Ingano y'ibinyampeke: | > 1 mm |

| Ubuso bwa Surface: | <0,3 mm RMS |

| Imashini & Amashanyarazi | |

| Gukomera: | 9-10 Mohs |

| Imbaraga zo kwikuramo: | 3-4 GPa |

| Imbaraga zikomeye: | 0.3-0.5 GPa |

| Gusenya Umwanya Imbaraga: | > 2 MV / cm |

| Ubworoherane bwa Dose: | > 10 Mrad |

| Ingaruka imwe Yingaruka Kurwanya: | > 100 MeV · cm² / mg |

| Amashanyarazi: | 150-380 W / m · K. |

| Gukoresha Ubushyuhe: | -55 kugeza 600 ° C. |

Ibintu by'ingenzi biranga

Monocrystalline SiC ya santimetero 6 kuri polycrystalline SiC igizwe na substrate itanga impuzandengo idasanzwe yimiterere yimikorere nimikorere, bigatuma ikenerwa nibidukikije byinganda:

1.Cost-Effectiveness: Shingiro ya polycrystalline SiC igabanya cyane ibiciro ugereranije na monocrystalline SiC yuzuye, mugihe monocrystalline SiC igaragara ikora neza murwego rwibikoresho, nibyiza kubisabwa byoroshye.

2.Ibikoresho bidasanzwe byamashanyarazi: Igice cya monocrystalline SiC cyerekana umuvuduko mwinshi wabatwara (> 500 cm² / V · s) hamwe nubucucike buke, bushigikira imikorere yumurongo mwinshi kandi ufite ingufu nyinshi.

3.Ubushyuhe bukabije-Ubushyuhe: SiC isanzwe irwanya ubushyuhe bwo hejuru (> 600 ° C) ituma insimburangingo ikomeza kuba itajegajega mubihe bikabije, bigatuma ibinyabiziga bikoresha amashanyarazi no gukoresha moteri yinganda.

Ubunini bwa 4,6-Ubunini bwa Wafer: Ugereranije na gakondo ya SiC ya santimetero 4, imiterere ya santimetero 6 yongerera umusaruro umusaruro wa chip hejuru ya 30%, bikagabanya ikiguzi cyibikoresho.

5.Igishushanyo mbonera: Imbere ya D-N cyangwa ubwoko bwa P igabanya intambwe zo gutera ion mugukora ibikoresho, kuzamura umusaruro numusaruro.

6.Icungamutungo Ryinshi: Ubushyuhe bwa polycrystalline SiC base (~ 120 W / m · K) yegera icya monocrystalline SiC, ikemura neza ibibazo byo gukwirakwiza ubushyuhe mubikoresho bifite ingufu nyinshi.

Ibi biranga umwanya wa santimetero 6 ziyobora monocrystalline SiC kuri polycrystalline SiC ikomatanya nkigisubizo cyo guhatanira inganda nkingufu zishobora kongera ingufu, ubwikorezi bwa gari ya moshi, hamwe nindege.

Porogaramu Yibanze

Monocrystalline SiC ya santimetero 6 kuri polycrystalline SiC compte substrate yoherejwe neza mubice byinshi bikenerwa cyane:

1.Ibikoresho by'amashanyarazi ya elegitoronike: Byakoreshejwe mumashanyarazi menshi ya SiC MOSFETs na diode kugirango byongere imikorere inverter no kwagura bateri (urugero, Tesla, moderi ya BYD).

2.Ibinyabiziga bitwara ibinyabiziga byo mu nganda: Bituma ubushyuhe bwo hejuru, bwihuta-bwihuta-modules yingufu, kugabanya gukoresha ingufu mumashini aremereye na turbine.

3.Ibikoresho bya Photovoltaic: Ibikoresho bya SiC bitezimbere izuba rihinduka (> 99%), mugihe substrate igizwe nibindi bigabanya ibiciro bya sisitemu.

4.Gutwara gari ya moshi: Bikoreshwa mubikurura bikurura sisitemu yihuta ya gari ya moshi na metero, bitanga imbaraga zo guhangana n’umuvuduko mwinshi (> 1700V) hamwe nimpamvu zifatika.

5.Icyogajuru: Nibyiza kuri sisitemu yingufu za satelite hamwe na moteri yindege igenzura, ishobora guhangana nubushyuhe bukabije nimirasire.

Mu guhimba bifatika, monocrystalline SiC ya santimetero 6 kuri polycrystalline SiC comprate substrate irahuza rwose nibikorwa bisanzwe bya SiC (urugero, lithographie, etching), bisaba ko nta shoramari ryiyongera.

Serivisi za XKH

XKH itanga ubufasha bwuzuye kuri monocrystalline SiC ya santimetero 6 kuri polycrystalline SiC ikomatanya, ikubiyemo R&D kugeza ku musaruro rusange:

1.Kwimenyekanisha: Guhindura umubyimba wa monocrystalline (5-100 mm), kwibanda kuri doping (1e15–1e19 cm⁻³), no kwerekana icyerekezo (4H / 6H-SiC) kugirango wuzuze ibisabwa bitandukanye.

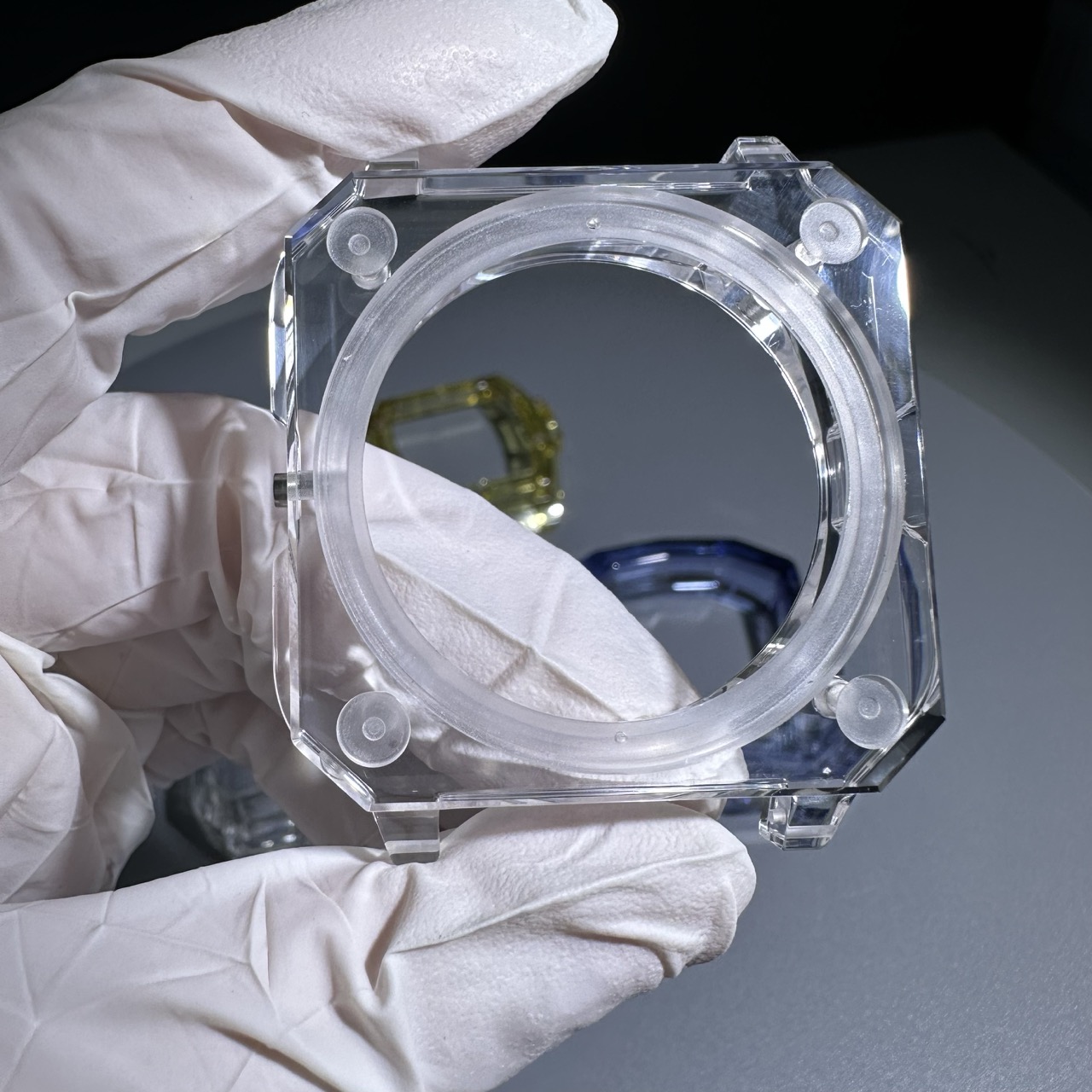

2.Itunganyirizwa rya Wafer: Isoko ryinshi rya santimetero 6 zubutaka hamwe no kunanura inyuma hamwe na serivise ya metallisation yo gucomeka no gukina.

3.Kwemeza tekiniki: Harimo isesengura rya XRD ya kristu, gupima ingaruka za Hall, hamwe no gupima ubushyuhe bwumuriro kugirango byihutishe ubumenyi bwibikoresho.

4.Rapid Prototyping: 2- kugeza kuri 4-ingero (inzira imwe) kubigo byubushakashatsi kugirango byihute byiterambere.

5.Gusesengura Kunanirwa & Optimisation: Ibisubizo-urwego rwibisubizo byo gutunganya ibibazo (urugero, inenge ya epitaxial layer).

Inshingano zacu ni ugushiraho monocrystalline SiC ya santimetero 6 kuri polycrystalline SiC comprate substrate nkigisubizo cyatoranijwe cyo gukora-ibikoresho bya elegitoroniki ya SiC, bitanga inkunga iherezo-iherezo kuva prototyping kugeza kubyara umusaruro.

Umwanzuro

Monocrystalline SiC ya santimetero 6 kuri polycrystalline SiC igizwe na substrate igera ku ntera ishimishije hagati yimikorere nigiciro binyuze muburyo bushya bwa mono / polycrystalline. Mugihe ibinyabiziga byamashanyarazi bigenda byiyongera ninganda 4.0 itera imbere, iyi substrate itanga umusingi wizewe wibikoresho bya elegitoroniki bizakurikiraho. XKH yishimiye ubufatanye kugirango turusheho gucukumbura ubushobozi bwa tekinoroji ya SiC.