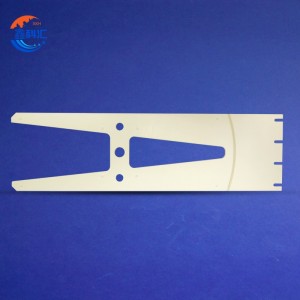

Imikorere-Yinshi ya Alumina Ceramic Iherezo Ryiza (Ukuboko kwamaboko) kuri Semiconductor na Automation Automation

Igishushanyo kirambuye

Kumenyekanisha ibicuruzwa

Alumina Ceramic End Effector, nanone yitwa amaboko ya ceramic cyangwa ukuboko kwamaboko ya ceramic, nikintu cyihariye cyo gutunganya ibintu cyagenewe sisitemu zikoresha mu buryo bwa semiconductor, Photovoltaic, kwerekana paneli, hamwe na laboratoire ifite isuku nyinshi. Yakozwe kugirango itange ubushyuhe budasanzwe, ubukana bwa mashini, hamwe n’imiti irwanya imiti, itanga ubwikorezi busukuye, bwizewe, kandi bwizewe bwibikoresho byoroshye nka waferi ya silicon, insimburangingo y'ibirahure, hamwe na mikoro ya elegitoroniki.

Nubwoko bwa robotic end effektor, iki kintu ceramic nigice cyanyuma hagati ya sisitemu yo gukora no gukora. Ifite uruhare runini mu kwimura neza, guhuza, gupakira / gupakurura, no gushyira imirimo mu bwiherero n’ibidukikije.

Incamake y'ibikoresho - Alumina Ceramic (Al₂O₃)

Alumina ceramic nigikoresho gihamye cyane kandi kijyanye na chimique tekinike ya ceramic izwiho kuba ifite imashini nziza n'amashanyarazi. Ubunini-bwiza (≥ 99.5%) alumina ikoreshwa muribi bikorwa byanyuma iremeza:

-

Gukomera cyane (Mohs 9): Icya kabiri gusa kuri diyama, alumina itanga kwihanganira kwambara cyane.

-

Ubushobozi bwo hejuru: Igumana ubusugire bwimiterere hejuru ya 1600 ° C.

-

Kutagira imiti: Kurwanya acide, alkalis, ibishishwa, hamwe na plasma itera ibidukikije.

-

Amashanyarazi: Hamwe n'imbaraga nyinshi za dielectric hamwe no gutakaza dielectric.

-

Kwiyongera k'ubushyuhe buke: Iremeza ituze rinini mubidukikije byamagare yubushyuhe.

-

Ibisekuru bito: Ibyingenzi muburyo bwo guhuza isuku (Icyiciro cya 10 kugeza Icyiciro 1000).

Ibiranga bituma alumina ceramic nziza kubikorwa byubutumwa bukomeye mubikorwa byangiza ibidukikije.

Imikorere

Imikorere ya alumina ceramic end ikoreshwa cyane mubikorwa byubuhanga buhanitse cyane cyane aho ibikoresho gakondo byuma cyangwa plastiki bigabanuka kubera kwaguka kwinshi, kwanduza, cyangwa ibibazo bya ruswa. Ibyingenzi byingenzi byo gusaba birimo:

- Semiconductor wafer kwimura

- Sisitemu yo gupakira no gupakurura

- Glass substrate ikora mumirongo ya OLED na LCD

- Crystalline silicon wafer ihererekanyabubasha ryizuba

- Igenzura ryikora ryikora cyangwa microelectronic igenzura

- Icyitegererezo cyo gutwara muri laboratoire yisesengura cyangwa ibinyabuzima

- Sisitemu yo gutangiza ibidukikije

Ubushobozi bwayo bwo gukora butabanje kwinjiza ibice cyangwa kwishyurwa bihamye bituma biba ingenzi kubikorwa bya robo byuzuye mubikorwa byogusukura.

Igishushanyo Ibiranga & Customisation

Buri ceramic end effektor yakozwe kugirango ihuze amaboko yihariye ya robo cyangwa sisitemu yo gufata wafer. Dushyigikiye ibyuzuye byuzuye bishingiye kuri:

-

Ingano ya Wafer: 2 ", 4", 6 ", 8", 12 "nibindi byinshi

-

Ahantu geometrie no gutandukanya: Yakira impande zifata, inkunga yinyuma, cyangwa igishushanyo cya wafer

-

Ibyambu: Imiyoboro ya vacuum ihuriweho cyangwa imiyoboro yo kudahuza

-

Iboneza: Imyobo, urudodo, uduce twerekanwe na robot yanyuma yibikoresho bya flange

-

Kuvura hejuru: Kurangiza, gukubitwa, cyangwa kurangiza neza (Ra <0.2 µm irahari)

-

Kurinda impande: Inguni zegeranye cyangwa gutondagura kugirango wirinde kwangirika kwa wafer

Ukoresheje ibishushanyo bya CAD cyangwa moderi ya 3D itangwa nabakiriya, injeniyeri zacu zirashobora guhitamo buri kuboko kwakabuto kuburemere, imbaraga, nisuku.

Ibyiza bya Ceramic End Ingaruka

| Ikiranga | Inyungu |

|---|---|

| Ubukanishi Bukuru | Igumana uburinganire buringaniye munsi yimashini zipakurura |

| Imikorere myiza yubushyuhe | Ikora neza muburyo bukabije-temp cyangwa plasma ibidukikije |

| Zero Yanduye | Nta ngaruka zo kwanduza ion mugutunganya igice cya kabiri |

| Ubuso buke | Kugabanya ibyago byo gushushanya kuri wafer cyangwa ibirahuri |

| Kurwanya-static na Non-Magnetic | Ntabwo ikurura umukungugu cyangwa ngo igire ingaruka kuri magnetiki |

| Ubuzima Burebure | Kurenza kwambara birwanya kwihuta kwihuta kwihuta |

| Ultra-Isuku Ihuza | Bikwiranye n'ubwiherero bwa ISO 14644 (Icyiciro cya 100 na munsi) |

Ugereranije nintwaro za plastiki cyangwa aluminium, ceramic ya alumina itanga uburyo butangaje bwimiti nu mubiri hamwe nibisabwa bike.

| Umutungo | Ukuboko kw'icyuma | Ukuboko kwa plastiki | Alumina Ceramic Arm |

|---|---|---|---|

| Gukomera | Guciriritse | Hasi | Hejuru cyane (Mohs 9) |

| Ubushyuhe bwumuriro | ≤ 500 ° C. | ≤ 150 ° C. | ≥ 1600 ° C. |

| Kurwanya imiti | Guciriritse | Abakene | Cyiza |

| Isuku ikwiye | Hagati | Hasi | Hejuru cyane |

| Kwambara Kurwanya | Hagati | Hasi | Indashyikirwa |

| Imbaraga za Dielectric | Hasi | Hagati | Hejuru |

| Gukoresha imashini yihariye | Ntarengwa | Guciriritse | Hejuru (± 0.01mm birashoboka) |

Ibisobanuro bya tekiniki

| Parameter | Agaciro |

|---|---|

| Ibikoresho | Alumina-yera cyane (≥ 99.5%) |

| Ubushyuhe bwo gukora | Kugera kuri 1600 ° C. |

| Ubuso | Ra ≤ 0.2 µm (bidashoboka) |

| Ingano ya Wafer Ingano | 2 "kugeza 12" cyangwa umuco |

| Ubworoherane | ± 0.01 mm (biterwa na porogaramu) |

| Inkunga yo Kunywa | Imiyoboro idahwitse, yihariye |

| Amahitamo yo gushiraho | Bolt-unyuze, flange, umwobo |

Ibibazo Bikunze Kubazwa (Ibibazo)

Q1: Impinduka zanyuma zishobora kwinjizwa muri sisitemu ya robo?

A1:Yego. Dushyigikiye kwihitiramo dushingiye kuri interineti ya robo. Urashobora kutwoherereza igishushanyo cya CAD cyangwa ibipimo bya flange kugirango tumenye neza.

Q2: Amaboko ya ceramic azavunika byoroshye mugihe cyo kuyakoresha?

A2:Mugihe ceramic yoroheje muri kamere, ibishushanyo byacu bikoresha geometrie nziza kugirango igabanye guhangayika. Mugihe gikwiye cyo gukoresha, batanga ubuzima burebure cyane kuruta ibyuma cyangwa plastike.

Q3: Birashoboka gukoresha ibi mubyumba bya ultra-high vacuum cyangwa plasma etching?

A3:Yego. Alumina ceramic ntabwo irenze urugero, ihagaze neza, kandi irwanya ruswa - ikwiranye neza na vacuum nyinshi, gaze idakira, cyangwa ibidukikije bya plasma.

Q4: Nigute ibi bice bisukurwa cyangwa bikomeza?

A4:Bashobora gusukurwa bakoresheje amazi ya DI, inzoga, cyangwa ibikoresho byogusukura. Nta kubungabunga bidasanzwe bikenewe kubera imiterere yimiti nubuso bwa inert.

Ibyerekeye Twebwe

XKH kabuhariwe mu iterambere ry’ikoranabuhanga rikomeye, gukora, no kugurisha ibirahuri bidasanzwe bya optique hamwe nibikoresho bishya bya kristu. Ibicuruzwa byacu bitanga ibikoresho bya elegitoroniki, ibikoresho bya elegitoroniki, n'abasirikare. Dutanga ibice bya optique ya optique, igifuniko cya terefone igendanwa, Ceramics, LT, Silicon Carbide SIC, Quartz, hamwe na semiconductor kristal wafers. Hamwe n'ubuhanga buhanga hamwe nibikoresho bigezweho, turi indashyikirwa mugutunganya ibicuruzwa bitari bisanzwe, tugamije kuba ibikoresho bya optoelectronic ibikoresho byubuhanga buhanitse.