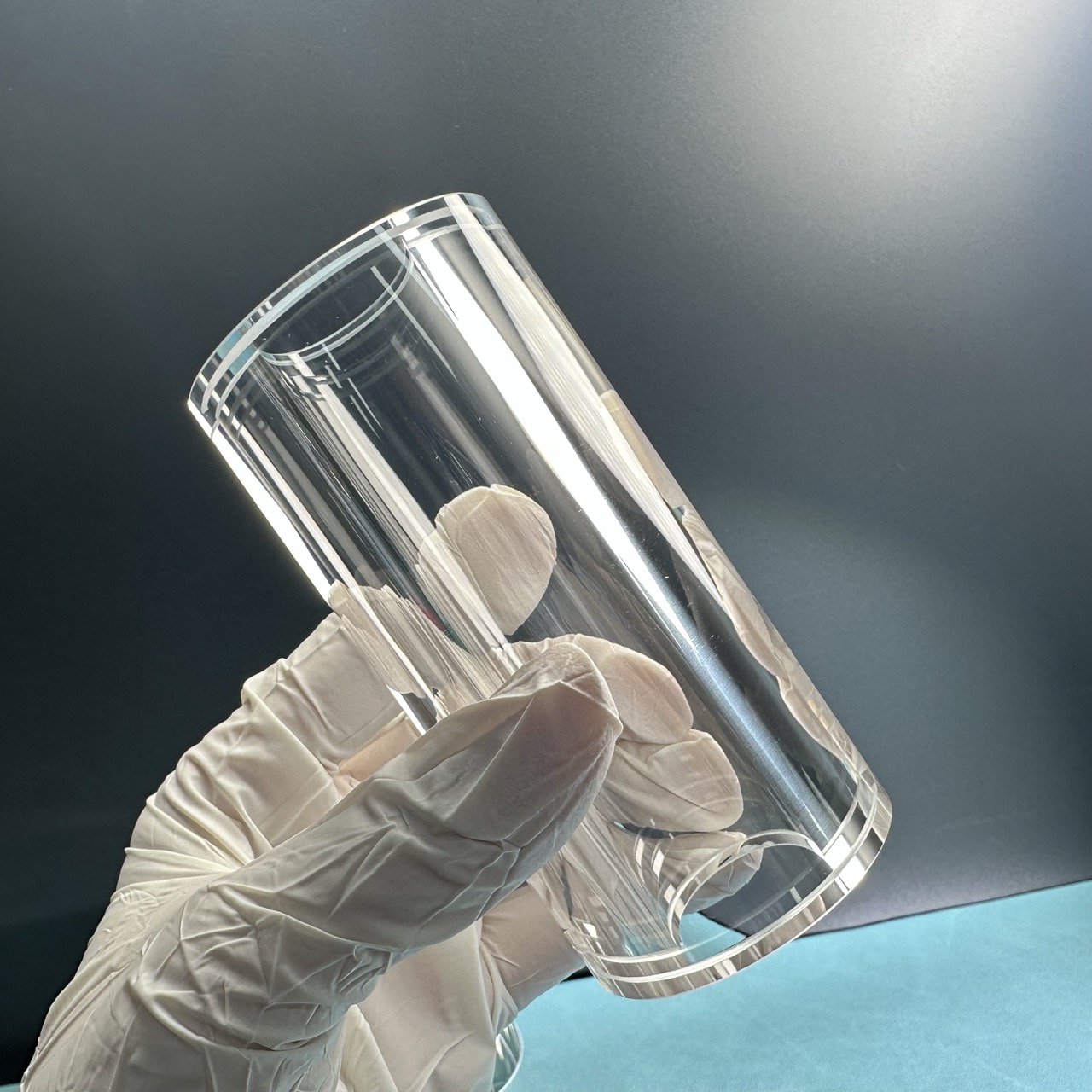

Byinshi-Byera Byahujwe na Quartz Wafers ya Semiconductor, Photonics Optical Porogaramu 2 ″ 4 ″ 6 ″ 8 ″ 12 ″

Igishushanyo kirambuye

Incamake yikirahure cya Quartz

Wafers ya Quartz ikora urufatiro rwibikoresho bitabarika bigezweho bitwara isi ya none. Kuva kugendagenda muri terefone yawe kugeza kumugongo wa sitasiyo ya 5G, quartz itanga ituze itanga ituze, isuku, nibisobanuro bisabwa mubikoresho bya elegitoroniki na fotonike. Haba gushyigikira imiyoboro yoroheje, gushoboza ibyuma bya MEMS, cyangwa gukora ishingiro rya comptabilite, imiterere yihariye ya quartz ituma iba ingenzi mu nganda.

"Fused Silica" cyangwa "Fused Quartz" aricyo cyiciro cya amorphous ya quartz (SiO2). Iyo ugereranije nikirahuri cya borosilike, silika yahujwe nta nyongeramusaruro; niyo mpamvu ibaho muburyo bwera, SiO2. Silica ikoreshwa ifite kwanduza cyane muri infragre na ultraviolet mugihe ugereranije nikirahure gisanzwe. Silica ikoreshwa ikorwa no gushonga no kongera gukomera ultrapure SiO2. Ku rundi ruhande, silika ya sintetike ihujwe ikozwe muri chimique ikungahaye kuri silicon nka SiCl4 ihumeka hanyuma igahumeka mu kirere cya H2 + O2. Umukungugu wa SiO2 wakozwe muriki kibazo wahujwe na silika kuri substrate. Ibice bya silika byahujwe byaciwemo waferi nyuma ya wafer irangiye.

Ibyingenzi byingenzi ninyungu za Quartz Glass Wafer

-

Ultra-Yera cyane (≥99.99% SiO2)

Icyiza kuri ultra-isuku ya semiconductor hamwe na fotonike aho ibintu bigomba kwanduzwa. -

Ikoreshwa ryinshi ryubushyuhe

Igumana ubunyangamugayo bwubaka kuva ubushyuhe bwa kirogenike bugera kuri 1100 ° C nta kurwanywa cyangwa gutesha agaciro. -

Ikwirakwizwa rya UV na IR

Itanga optique isobanutse neza kuva ultraviolet (DUV) ikoresheje hafi-ya-infragre (NIR), ishyigikira neza optique ya optique. -

Coefficient yo Kwagura Ubushyuhe Buke

Kuzamura ihame ryimiterere ihindagurika ryubushyuhe, kugabanya imihangayiko no kunoza imikorere. -

Kurwanya Kurwanya Imiti

Shyiramo acide nyinshi, alkalis, hamwe na solvets - bigatuma bikwiranye nibidukikije bitera imiti. -

Ubuso Burangiza Guhinduka

Iraboneka hamwe na ultra-yoroshye, uruhande rumwe cyangwa impande ebyiri zisize neza, zihuza na fotonike nibisabwa MEMS.

Uburyo bwo Gukora Ikirahure cya Quartz

Wafer ya quartz ikoreshwa ikoresheje urukurikirane rwintambwe igenzurwa kandi yuzuye:

-

Guhitamo Ibikoresho

Guhitamo kwiza-kwiza kwinshi kwiza cyangwa inkomoko ya SiO₂. -

Gushonga no Guhuza

Quartz yashonga kuri ~ 2000 ° C mu itanura ryamashanyarazi munsi yikirere kigenzurwa kugirango ikureho ibibyimba byinshi. -

Guhagarika gushiraho

Silika yashongeshejwe ikonjeshwa mubice bikomeye cyangwa ingoti. -

Gukata Wafer

Diyama cyangwa insinga zuzuye zikoreshwa mugukata ingobo mubusa. -

Gukubita no Kuringaniza

Ubuso bwombi buringaniye kandi buringaniye kugirango buhuze neza neza, uburebure, hamwe nubusobanuro bwihariye. -

Isuku & Kugenzura

Wafers isukurwa mucyumba cy’isuku cya ISO 100/1000 kandi igenzurwa cyane ku nenge no guhuza ibipimo.

Ibyiza bya Quartz Glass wafer

| ing | igice | 4" | 6" | 8" | 10 " | 12 " |

|---|---|---|---|---|---|---|

| Diameter / ingano (cyangwa kare) | mm | 100 | 150 | 200 | 250 | 300 |

| Ubworoherane (±) | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Umubyimba | mm | 0.10 cyangwa irenga | 0.30 cyangwa irenga | 0.40 cyangwa irenga | 0.50 cyangwa irenga | 0.50 cyangwa irenga |

| Ikibanza cyibanze | mm | 32.5 | 57.5 | Igice cya kabiri | Igice cya kabiri | Igice cya kabiri |

| LTV (5mm × 5mm) | μm | <0.5 | <0.5 | <0.5 | <0.5 | <0.5 |

| TTV | μm | <2 | <3 | <3 | <5 | <5 |

| Umuheto | μm | ± 20 | ± 30 | ± 40 | ± 40 | ± 40 |

| Intambara | μm | ≤ 30 | ≤ 40 | ≤ 50 | ≤ 50 | ≤ 50 |

| PLTV (5mm × 5mm) <0.4 mm | % | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% |

| Uruziga | mm | Kubahiriza SEMI M1.2 Bisanzwe / reba IEC62276 | ||||

| Ubwoko bw'Ubuso | Uruhande rumwe rusize / Impande ebyiri Zasizwe | |||||

| Uruhande rusize Ra | nm | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Ibipimo by'inyuma | μm | rusange 0.2-0.7 cyangwa yihariye | ||||

Quartz vs Ibindi bikoresho bisobanutse

| Umutungo | Ikirahuri cya Quartz | Ikirahuri cya Borosilicate | Safiro | Ikirahure gisanzwe |

|---|---|---|---|---|

| Ikigereranyo Cyinshi | ~ 1100 ° C. | ~ 500 ° C. | ~ 2000 ° C. | ~ 200 ° C. |

| Ikwirakwizwa rya UV | Neza (JGS1) | Abakene | Nibyiza | Abakene cyane |

| Kurwanya imiti | Cyiza | Guciriritse | Cyiza | Abakene |

| Isuku | Hejuru cyane | Hasi kugeza ku rugero | Hejuru | Hasi |

| Kwagura Ubushyuhe | Hasi cyane | Guciriritse | Hasi | Hejuru |

| Igiciro | Gereranya kugeza hejuru | Hasi | Hejuru | Hasi cyane |

Ibibazo bya Quartz Ikirahure Wafer

Q1: Ni irihe tandukaniro riri hagati ya quartz yahujwe na silika yahujwe?

Mugihe byombi ari amorphous ya SiO₂, quartz yahujwe mubisanzwe ikomoka kumasoko karemano, mugihe silika yahujwe ikorwa muburyo bumwe. Mu mikorere, batanga imikorere isa, ariko silika yahujwe irashobora kugira ubuziranenge burenze gato hamwe nuburinganire.

Q2: Wafer ya quartz yahujwe irashobora gukoreshwa mubidukikije-vacuum?

Yego. Bitewe nubushobozi buke bwo gusohora hamwe nubushyuhe bukabije bwumuriro, wafers ya quartz yahujwe nibyiza kuri sisitemu ya vacuum hamwe nogukoresha ikirere.

Q3: Ese izi wafer zikwiranye na progaramu ya UV yimbitse?

Rwose. Quartz ikoreshwa ifite transmitment nyinshi kugeza kuri ~ 185 nm, bigatuma iba nziza kuri optique ya DUV, masike ya lithographie, hamwe na sisitemu ya laser ya excimer.

Q4: Ushyigikiye ibihimbano bya wafer?

Yego. Dutanga ibyuzuye byuzuye harimo diameter, ubunini, ubwiza bwubuso, igorofa / udusanduku, hamwe na laser, ukurikije ibyo usabwa byihariye.

Ibyerekeye Twebwe

XKH kabuhariwe mu iterambere ry’ikoranabuhanga rikomeye, gukora, no kugurisha ibirahuri bidasanzwe bya optique hamwe nibikoresho bishya bya kristu. Ibicuruzwa byacu bitanga ibikoresho bya elegitoroniki, ibikoresho bya elegitoroniki, n'abasirikare. Dutanga ibice bya optique ya optique, igifuniko cya terefone igendanwa, Ceramics, LT, Silicon Carbide SIC, Quartz, hamwe na semiconductor kristal wafers. Hamwe n'ubuhanga buhanga hamwe nibikoresho bigezweho, turi indashyikirwa mugutunganya ibicuruzwa bitari bisanzwe, tugamije kuba ibikoresho bya optoelectronic ibikoresho byubuhanga buhanitse.