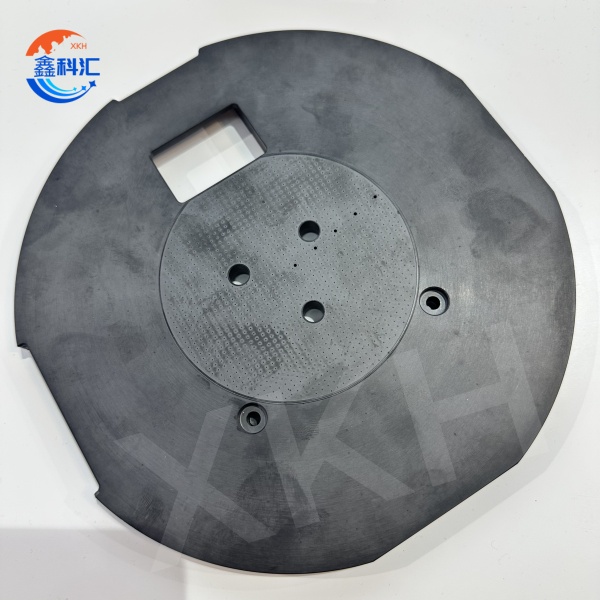

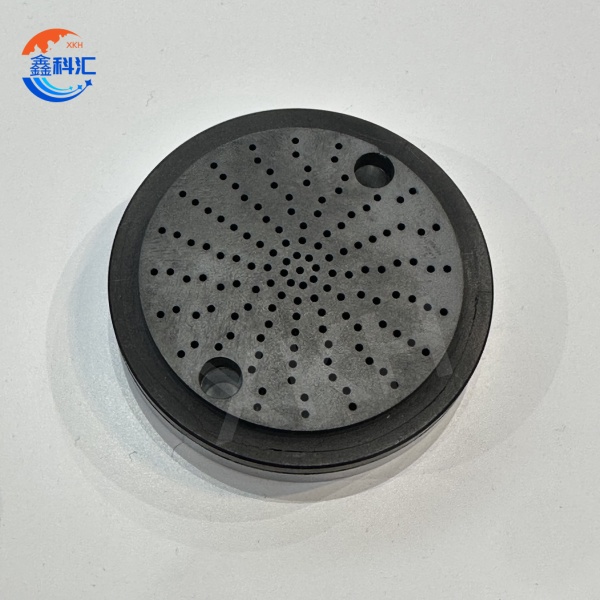

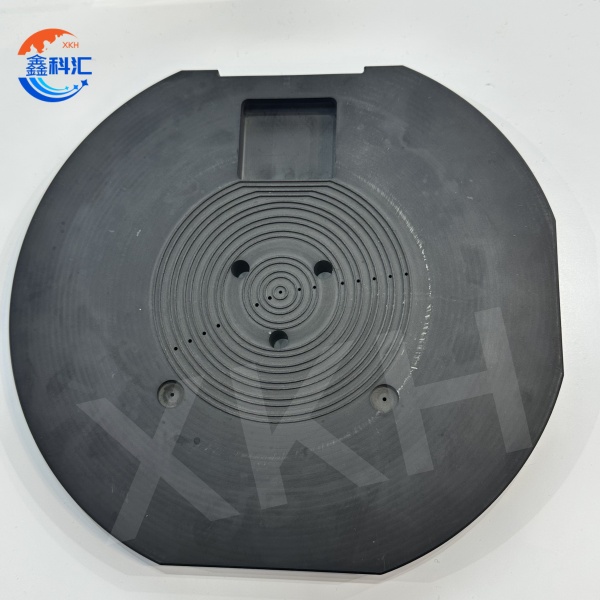

SiC ceramic chuck tray Ceramic suction ibikombe neza gutunganya neza

Ibiranga ibikoresho:

1.Ubukomere bukomeye: Mohs ubukana bwa karubide ya silicon ni 9.2-9.5, icya kabiri nyuma ya diyama, hamwe no kwihanganira kwambara.

.

3. Coefficient yo kwagura ubushyuhe buke: silicon karbide yo kwagura amashyanyarazi ni mike (4.0-4.5 × 10⁻⁶ / K), irashobora gukomeza guhagarara neza mubushyuhe bwinshi.

.

5.

Ibiranga:

1.Mu nganda za semiconductor, waferi yoroheje cyane igomba gushyirwa ku gikombe cyokunywa vacuum, gusohora vacuum bikoreshwa mugukosora waferi, kandi inzira yo gushashara, kunanuka, ibishashara, gusukura no gukata bikorerwa kuri wafer.

2.Silicon karbide yonsa ifite ubushyuhe bwiza bwumuriro, irashobora kugabanya neza igihe cyibishashara nigishashara, kunoza umusaruro.

3.Silicon carbide vacuum sucker nayo ifite aside nziza hamwe na alkali irwanya ruswa.

4. Ugereranije na plaque gakondo ya corundum itwara, gabanya igihe cyo gupakira no gupakurura igihe cyo gushyushya no gukonjesha, kunoza imikorere; Muri icyo gihe, irashobora kugabanya kwambara hagati yisahani yo hejuru no hepfo, ikagumana indege nziza, kandi ikongerera igihe cya serivisi hafi 40%.

5.Ibintu bifatika ni bito, uburemere bworoshye. Biroroshye kubakoresha gutwara pallets, kugabanya ibyago byo kugongana byatewe ningorane zo gutwara abantu hafi 20%.

6.Ubunini: diameter ntarengwa 640mm; Kureshya: 3um cyangwa munsi yayo

Umwanya wo gusaba:

1. Gukora Semiconductor

Processing Gutunganya Wafer:

Kugirango wafer ikosorwe muri Photolithography, etching, gushira firime yoroheje nibindi bikorwa, byemeza neza neza kandi bihamye. Ubushyuhe bwo hejuru hamwe no kurwanya ruswa bikwiranye n’ibikorwa bikaze bya semiconductor.

Growth Gukura kwa Epitaxial:

Muri SiC cyangwa GaN gukura epitaxial, nkumutwara wo gushyushya no gutunganya waferi, kwemeza ubushyuhe hamwe nubuziranenge bwa kristu mubushyuhe bwinshi, kunoza imikorere yibikoresho.

2. Ibikoresho by'amashanyarazi

LED Gukora LED:

Byakoreshejwe mugukosora amabuye ya safiro cyangwa SiC, kandi nkikintu gitwara ubushyuhe muri gahunda ya MOCVD, kugirango habeho uburinganire bwikura rya epitaxial, kunoza imikorere ya LED nubuziranenge.

Ode Laser diode:

Nkibisobanuro bihanitse, gutunganya no gushyushya substrate kugirango ubushyuhe bwubushyuhe butajegajega, kuzamura imbaraga zisohoka nubwizerwe bwa diode ya laser.

3. Gutunganya neza

Processing Ibikoresho bitunganijwe neza:

Ikoreshwa mugukosora ibice bisobanutse neza nka optique ya optique na filteri kugirango harebwe neza neza n’umwanda muke mugihe cyo kuyitunganya, kandi ikwiriye gukoreshwa cyane.

Processing Gutunganya ibumba:

Nkibikoresho bihamye bihamye, birakwiriye gutunganywa neza ibikoresho byubutaka kugirango habeho gutunganya neza no guhora munsi yubushyuhe bwinshi nibidukikije byangirika.

4. Ubushakashatsi bwa siyansi

Experiment Ubushyuhe bwo hejuru:

Nkicyitegererezo cyogukosora mubushyuhe bwo hejuru, gishyigikira ubushakashatsi bukabije bwubushyuhe buri hejuru ya 1600 ° C kugirango harebwe ubushyuhe hamwe nicyitegererezo gihamye.

Test Ikizamini cya Vacuum:

Nkicyitegererezo cyo gutunganya no gushyushya ibintu mubidukikije bya vacuum, kugirango harebwe niba ubushakashatsi bwakorwa neza kandi busubirwamo, bubereye gutwika no kuvura ubushyuhe.

Ibisobanuro bya tekiniki :

| (Umutungo w'ibikoresho) | (Igice) | (ssic) | |

| (Ibirimo SiC) |

| (Wt)% | > 99 |

| (Impuzandengo y'ingano) |

| micron | 4-10 |

| (Ubucucike) |

| kg / dm3 | > 3.14 |

| (Ikigaragara ni uko) |

| Vo1% | <0.5 |

| (Gukomera kwa Vickers) | HV 0.5 | GPa | 28 |

| * (Imbaraga zidasanzwe) | 20ºC | MPa | 450 |

| (Imbaraga zo guhonyora) | 20ºC | MPa | 3900 |

| (Moderi ya Elastike) | 20ºC | GPa | 420 |

| (Gukomera kuvunika) |

| MPa / m '% | 3.5 |

| (Ubushyuhe bwa Thermal) | 20 ° ºC | W / (m * K) | 160 |

| (Kurwanya) | 20 ° ºC | Ohm.cm | 106-108 |

|

| a (RT ** ... 80ºC) | K-1 * 10-6 | 4.3 |

|

|

| oºC | 1700 |

Hamwe nimyaka myinshi yo gukusanya tekinike hamwe nuburambe mu nganda, XKH ibasha guhuza ibipimo byingenzi nkubunini, uburyo bwo gushyushya hamwe na vacuum adsorption igishushanyo cya chuck ukurikije ibyo umukiriya akeneye, byemeza ko ibicuruzwa byahujwe neza nibikorwa byabakiriya. SiC silicon karbide ceramic chucks yabaye nkibintu byingenzi mugutunganya wafer, gukura kwa epitaxial nibindi bikorwa byingenzi bitewe nubushyuhe bwiza bwumuriro, ubushyuhe bwinshi nubushyuhe bwimiti. By'umwihariko mu gukora ibikoresho bya semiconductor yo mu gisekuru cya gatatu nka SiC na GaN, icyifuzo cya silicon carbide ceramic chucks gikomeje kwiyongera. Mu bihe biri imbere, hamwe niterambere ryihuse rya 5G, ibinyabiziga byamashanyarazi, ubwenge bwubukorikori nubundi buryo bwikoranabuhanga, ibyifuzo byo gukoresha silicon carbide ceramic chucks mu nganda za semiconductor bizaba binini.

Igishushanyo kirambuye