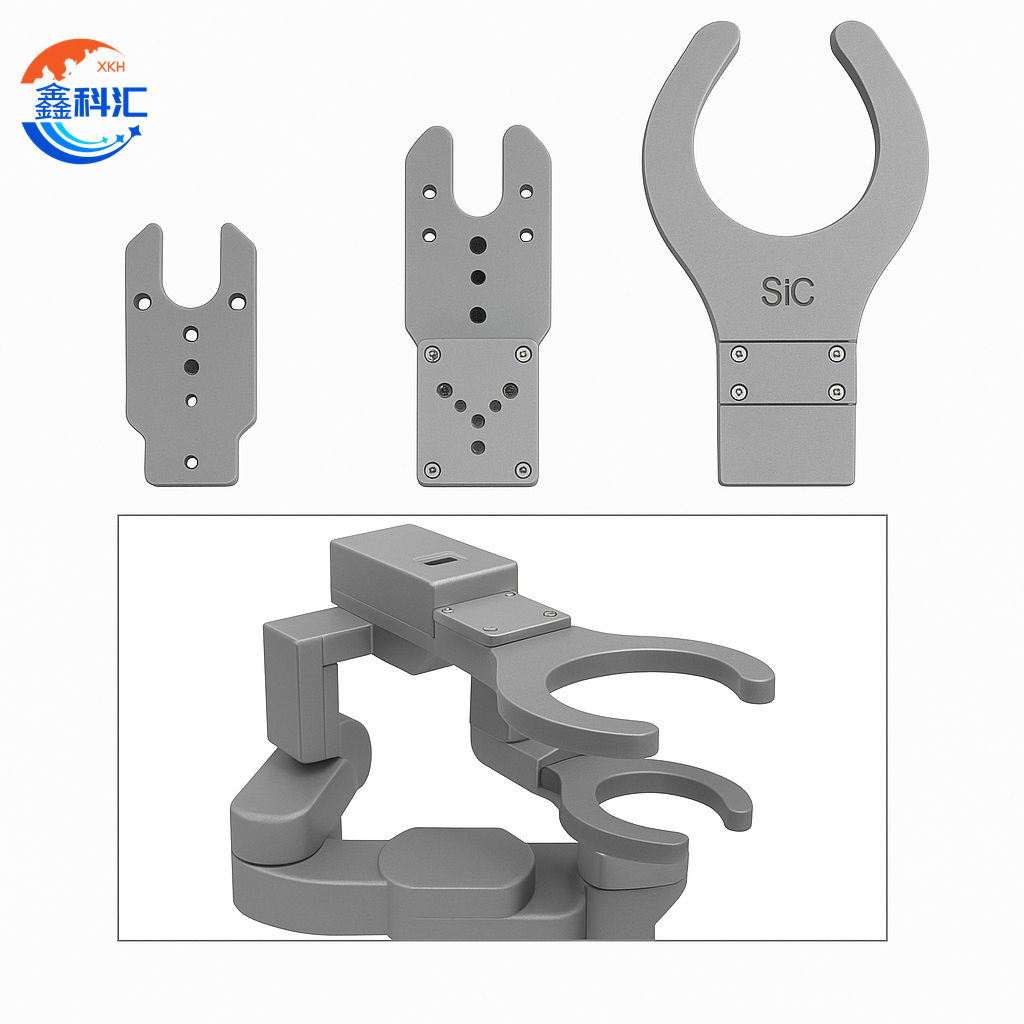

SiC ceramic end effector itanga ukuboko kwa wafer

SiC ceramic end effector Abstract

SiC (Silicon Carbide) ceramic end-effector ni ikintu cyingenzi muri sisitemu yo gutunganya neza wafer ikoreshwa mu gukora semiconductor hamwe n’ibidukikije bigezweho. Byakozwe kugirango byuzuze ibisabwa bisabwa cyane cyane-bisukuye, ubushyuhe bwo hejuru, hamwe n’ibidukikije bihamye cyane, iyi mikorere yihariye ituma ubwikorezi bwizewe kandi butanduzwa na wafers mugihe cyintambwe zingenzi zibyara umusaruro nka lithographie, kurigata, no kubitsa.

Gukoresha ibintu byiza cyane bya karubide ya silikoni-nkumuvuduko mwinshi wumuriro, ubukana bukabije, kutagira imiti ihebuje, hamwe no kwaguka kwinshi kwumuriro-SiC ceramic end-effector itanga ubukana butagereranywa bwimikorere ndetse no gutuza kurwego ndetse no mumagare yihuta yubushyuhe cyangwa mubyumba byangirika. Ibice byayo bito hamwe nibiranga plasma birwanya cyane cyane muburyo bwogukora isuku hamwe nogutunganya vacuum, aho kubungabunga ubusugire bwa wafer no kugabanya kwanduza ibice byingenzi.

SiC ceramic iherezo ryimikorere Porogaramu

1. Gukoresha Semiconductor Wafer

Imikorere ya SiC ceramic end ikoreshwa cyane muruganda rwa semiconductor mugutunganya wafer ya silicon mugihe cyo gukora byikora. Izi ngaruka zanyuma zishyirwa kumaboko ya robo cyangwa sisitemu yo kohereza vacuum kandi igenewe kwakira wafer yubunini butandukanye nka 200mm na 300mm. Nibyingenzi mubikorwa birimo Gutanga Imyuka Yumuyaga (CVD), Kubika Imyuka Yumubiri (PVD), kuribwa, no gukwirakwizwa - aho ubushyuhe bwinshi, imiterere ya vacuum, na gaze yangirika bikunze kugaragara. SiC idasanzwe yo kurwanya ubushyuhe hamwe nubushakashatsi bwimiti ituma iba ibikoresho byiza byo guhangana n’ibidukikije bikaze nta kwangirika.

2. Guhuza Isuku na Vacuum

Mu isuku n’imyanya ya vacuum, aho ibice byanduye bigomba kugabanuka, ububumbyi bwa SiC butanga ibyiza byingenzi. Ubucucike bwibintu byoroshye, birwanya kubyara ibice, bifasha kugumana ubusugire bwa wafer mugihe cyo gutwara. Ibi bituma amaherezo ya SiC akwiranye cyane nibikorwa bikomeye nka Ultraviolet Lithography (EUV) na Atomic Layer Deposition (ALD), aho isuku ari ngombwa. Byongeye kandi, SiC yo hasi cyane hamwe na plasma irwanya imbaraga bituma imikorere yizewe mubyumba bya vacuum, ikongerera igihe cyibikoresho no kugabanya inshuro zo kubungabunga.

3. Sisitemu yo hejuru cyane

Icyitonderwa kandi gihamye ningirakamaro muri sisitemu yo gutunganya wafer igezweho, cyane cyane muri metero, kugenzura, no guhuza ibikoresho. Ubukorikori bwa SiC bufite coefficient nkeya cyane yo kwaguka k'ubushyuhe no gukomera gukomeye, ibyo bikaba bituma impera yanyuma ikomeza kuba inyangamugayo ndetse no munsi yumukino wo gusiganwa ku magare cyangwa umutwaro wa mashini. Ibi byemeza ko wafers ikomeza guhuzwa neza mugihe cyo gutwara abantu, bikagabanya ingaruka ziterwa na micro-scratches, kudahuza, cyangwa amakosa yo gupimwa - ibintu bigenda binenga cyane kuri sub-5nm.

SiC ceramic iherezo ryimikorere

1. Imbaraga Zikomeye Zikomeye nubukomere

Ubukorikori bwa SiC bufite imbaraga zidasanzwe zubukanishi, hamwe nimbaraga zihindagurika akenshi zirenga 400 MPa na Vickers agaciro gakomeye hejuru ya 2000 HV. Ibi bituma barwanya cyane imihangayiko, ingaruka, no kwambara, nubwo nyuma yo gukoresha igihe kirekire. Ubukomezi bukabije bwa SiC bugabanya kandi gutandukana mugihe cyihuta cyoherejwe na wafer, byemeza neza kandi neza.

2. Ubushyuhe buhebuje

Kimwe mu bintu by'agaciro biranga ubukorikori bwa SiC ni ubushobozi bwabo bwo guhangana n'ubushyuhe bwo hejuru cyane - akenshi bugera kuri 1600 ° C mu kirere cya inert - nta gutakaza ubunyangamugayo. Coefficient nkeya yo kwagura ubushyuhe (~ 4.0 x 10⁻⁶ / K) itanga ituze ryikigereranyo munsi yubushyuhe bwumuriro, bigatuma biba byiza mubisabwa nka CVD, PVD, hamwe nubushyuhe bwo hejuru.

SiC ceramic impera yanyuma Q&A

Ikibazo : Ni ibihe bikoresho bikoreshwa muri wafer ya nyuma?

A :Imikorere ya Wafer isanzwe ikorwa mubikoresho bitanga imbaraga nyinshi, ubushyuhe bwumuriro, hamwe nuduce duto duto. Muri ibyo, Silicon Carbide (SiC) ceramic nimwe mubikoresho byateye imbere kandi bikunzwe. Ubukorikori bwa SiC burakomeye cyane, butajegajega cyane, butera imiti, kandi ntibushobora kwambara, bigatuma buba bwiza bwo gutunganya wafer ya silikoni yoroshye mu isuku n’ahantu hatuje. Ugereranije na quartz cyangwa ibyuma bisize, SiC itanga ihame ryo hejuru murwego rwo hejuru mubushyuhe bwinshi kandi ntisuka ibice, bifasha kwirinda kwanduza.