SiC ceramic plate / tray kuri 4inch 6inch wafer ufite ICP

SiC ceramic plate Abstract

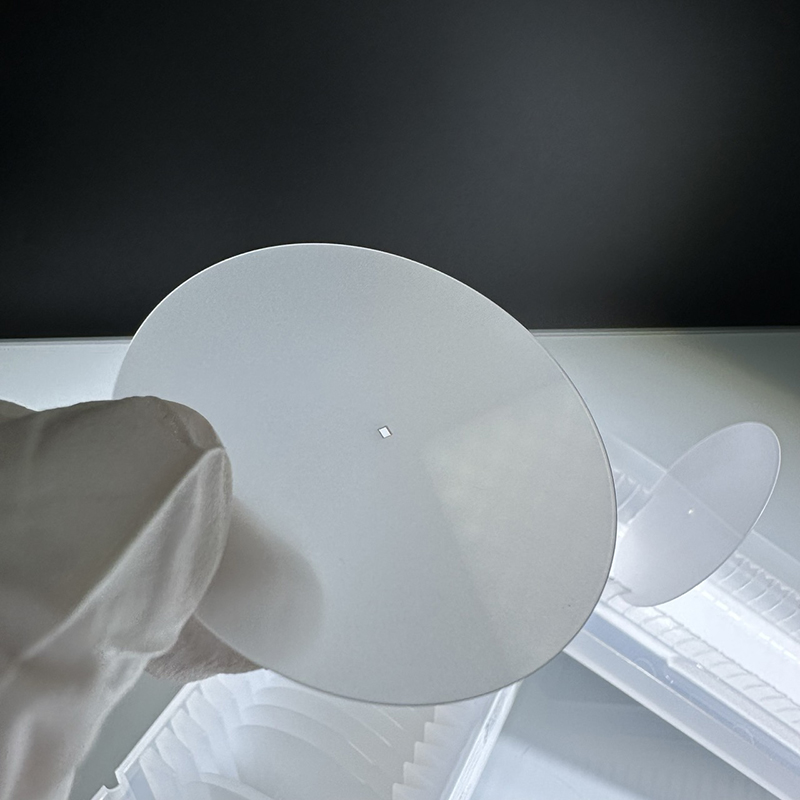

Isahani yububiko bwa SiC nigice kinini cyibikorwa byakozwe na Silicon Carbide ifite isuku nyinshi, yagenewe gukoreshwa mubushuhe bukabije, imiti, nubukanishi. Azwi cyane kubera ubukana budasanzwe, ubushyuhe bwumuriro, hamwe no kurwanya ruswa, isahani ya SiC ikoreshwa cyane nkuwitwa wafer, susceptor, cyangwa ibice byubaka mubice bya semiconductor, LED, Photovoltaque, ninganda zo mu kirere.

Hamwe nubushyuhe buhebuje bugera kuri 1600 ° C hamwe no kurwanya imyuka ihumanya hamwe n’ibidukikije bya plasma, isahani ya SiC itanga imikorere ihamye mugihe cy'ubushyuhe bwo hejuru cyane, kubitsa, no gukwirakwiza. Ubucucike bwacyo, butagira isuku microstructure bigabanya kubyara ibice, bigatuma biba byiza mubikorwa byogusukura cyane mumwanya wa vacuum cyangwa isuku.

Isahani ya ceramic

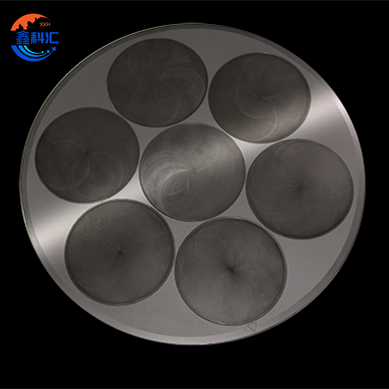

1. Gukora Semiconductor

Isahani ya ceramic isanzwe ikoreshwa nkabatwara wafer, suseptors, hamwe nicyapa cyicyuma mubikoresho byo guhimba semiconductor nka CVD (Chemical Vapor Deposition), PVD (Depical Vapor Deposition), hamwe na sisitemu yo gutobora. Ubwinshi bwumuriro mwiza hamwe no kwaguka kwubushyuhe buke bubafasha gukomeza gukwirakwiza ubushyuhe bumwe, nibyingenzi mugutunganya neza neza wafer. Kurwanya SiC kurwanya imyuka yangiza na plasmas bituma iramba ahantu habi, ifasha kugabanya kwanduza no gufata neza ibikoresho.

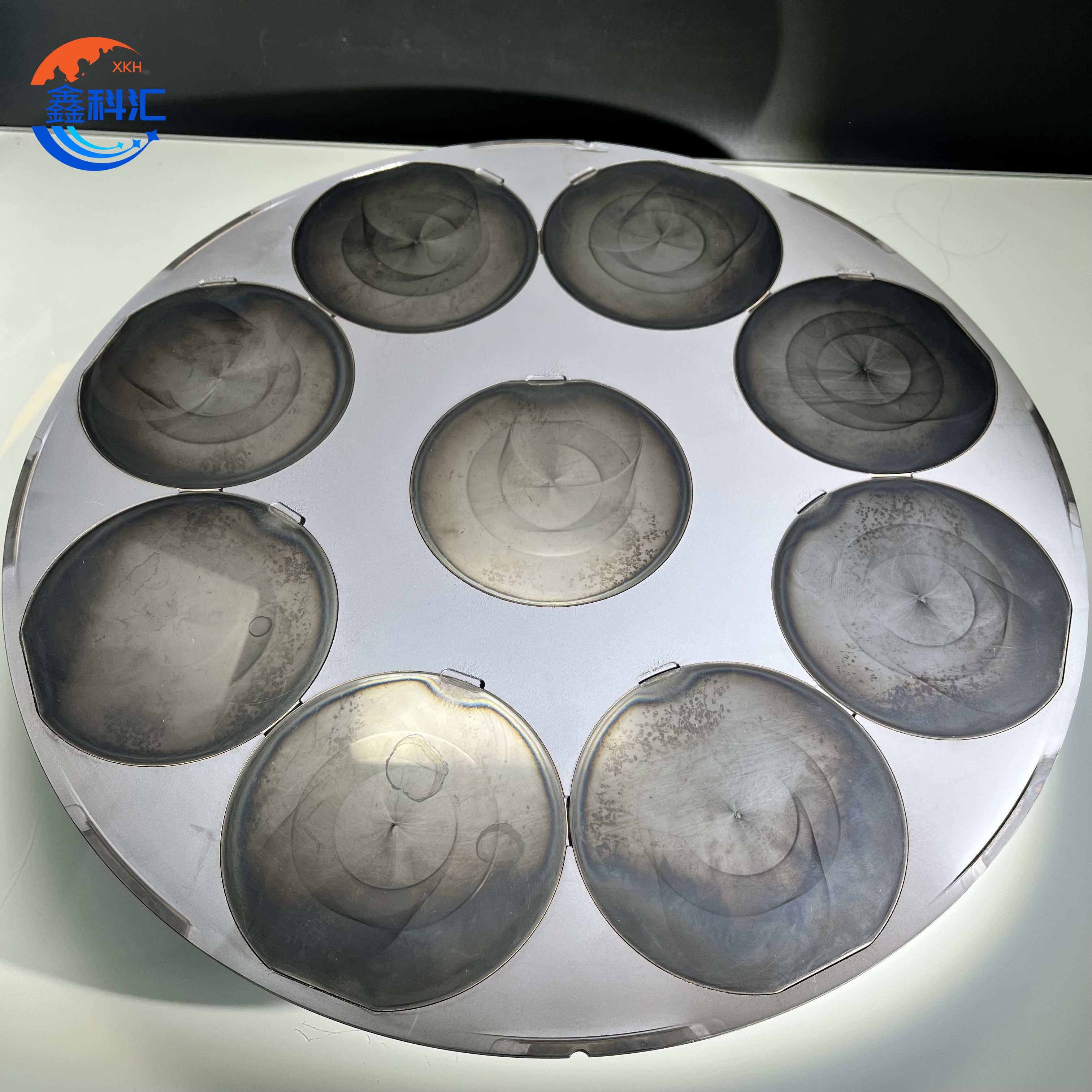

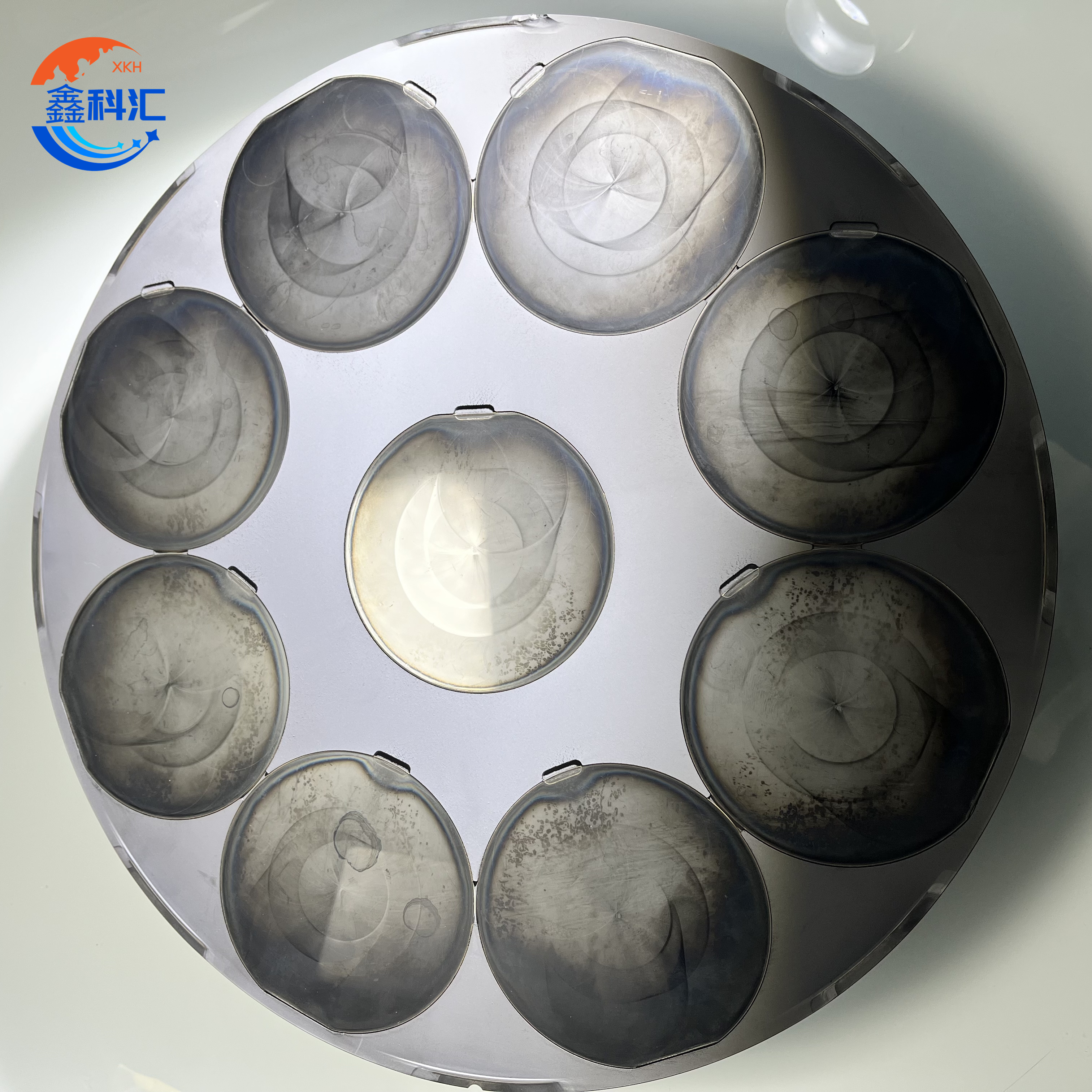

2. Inganda LED - Gutera ICP

Mu rwego rwo gukora LED, ibyapa bya SiC nibice byingenzi muri sisitemu yo guteramo ICP (Inductively Coupled Plasma). Gukora nk'abafite wafer, batanga urubuga ruhamye kandi rukomeye kugirango rushyigikire safiro cyangwa GaN mugihe cyo gutunganya plasma. Kurwanya plasma nziza cyane, kuburinganire bwubuso, hamwe no guhagarara neza bifasha kwemeza neza neza kandi neza, biganisha ku kongera umusaruro no gukora ibikoresho muri chip ya LED.

3. Photovoltaics (PV) ningufu zizuba

Isahani yububiko bwa SiC nayo ikoreshwa mugukora izuba, cyane cyane mugihe cyo hejuru yubushyuhe bwo hejuru no gutera intambwe. Ubusembure bwabo mubushyuhe bwo hejuru hamwe nubushobozi bwo kurwanya imirwanyasuri bituma gutunganya neza wafer ya silicon. Byongeye kandi, ibyago byabo byanduye ni ngombwa mugukomeza gukora selile zifotora.

SiC ceramic plaque Ibyiza

1. Imbaraga zidasanzwe za mashini nubukomere

Isahani yububiko bwa SiC yerekana imbaraga zubukanishi cyane, hamwe nimbaraga zisanzwe zirenga 400 MPa naho ubukana bwa Vickers bugera> 2000 HV. Ibi bituma barwanya cyane kwambara imashini, gukuramo, no guhindura ibintu, bigatuma ubuzima bumara igihe kirekire nubwo buremereye cyane cyangwa gusiganwa ku magare.

2. Ubushyuhe bwo hejuru cyane

SiC ifite ubushyuhe bwiza cyane (ubusanzwe 120–200 W / m · K), butuma ikwirakwiza neza ubushyuhe hejuru yayo. Uyu mutungo ni ingenzi mubikorwa nka wafer etching, kubitsa, cyangwa gucumura, aho ubushyuhe bwubushyuhe bugira ingaruka kumasoko yibicuruzwa nubwiza.

3. Ubushyuhe bwo hejuru bwumuriro

Hamwe no gushonga cyane (2700 ° C) hamwe na coefficient nkeya yo kwagura ubushyuhe (4.0 × 10⁻⁶ / K), plaque ceramic ya SiC igumana uburinganire bwuzuye nuburinganire bwuburinganire mugihe cyihuta cyo gushyuha no gukonja. Ibi bituma biba byiza mubisabwa mu ziko ryubushyuhe bwo hejuru, ibyumba bya vacuum, hamwe na plasma ibidukikije.

| Ibyiza bya tekiniki | ||||

| Ironderero | Igice | Agaciro | ||

| Izina ryibikoresho | Igisubizo Cyacuzwe na Silicon Carbide | Carbide ya Silicon idafite imbaraga | Carbide yongeye gushyirwaho | |

| Ibigize | RBSiC | SSiC | R-SiC | |

| Ubucucike bwinshi | g / cm3 | 3 | 3.15 ± 0.03 | 2.60-2.70 |

| Imbaraga zoroshye | MPa (kpsi) | 338 (49) | 380 (55) | 80-90 (20 ° C) 90-100 (1400 ° C) |

| Imbaraga zo guhonyora | MPa (kpsi) | 1120 (158) | 3970 (560) | > 600 |

| Gukomera | Knoop | 2700 | 2800 | / |

| Gucika intege | MPa m1 / 2 | 4.5 | 4 | / |

| Amashanyarazi | W / mk | 95 | 120 | 23 |

| Coefficient yo Kwagura Ubushyuhe | 10-6.1 / ° C. | 5 | 4 | 4.7 |

| Ubushyuhe bwihariye | Joule / g 0k | 0.8 | 0.67 | / |

| Ubushyuhe bwinshi mu kirere | ℃ | 1200 | 1500 | 1600 |

| Modulus | Gpa | 360 | 410 | 240 |

Isahani yububiko bwa SiC Ikibazo

Ikibazo : Ni ibihe bintu biranga isahani ya karibide?

A : Amashanyarazi ya silicon (SiC) azwiho imbaraga nyinshi, gukomera, hamwe nubushyuhe bwumuriro. Zitanga ubushyuhe bwiza bwumuriro no kwagura ubushyuhe buke, zitanga imikorere yizewe mubushyuhe bukabije. SiC kandi ni chimique inert, irwanya acide, alkalis, na plasma ibidukikije, bigatuma biba byiza kuri semiconductor no gutunganya LED. Ubuso bwacyo, buringaniye bugabanya kubyara ibice, bikomeza ubwiherero. Isahani ya SiC ikoreshwa cyane nkabatwara wafer, suseptors, hamwe nibikoresho bifasha mubushyuhe bwo hejuru hamwe nibidukikije byangirika hakurya ya semiconductor, Photovoltaic, ninganda zo mu kirere.