SiC Ceramic Tray kubatwara Wafer hamwe nubushyuhe bwo hejuru

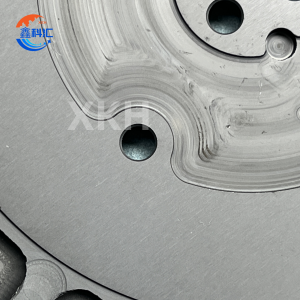

Silicon Carbide Ceramic Tray (SiC Tray)

Ibikoresho byiza cyane byubutaka bushingiye kubintu bya silicon karbide (SiC), byakozwe mubikorwa byinganda byateye imbere nko gukora semiconductor no gukora LED. Ibikorwa byayo byingenzi birimo gukora nka wafer, urubuga rwo gutondeka, cyangwa inkunga yubushyuhe bwo hejuru, gukoresha ingufu zidasanzwe zidasanzwe, kurwanya ubushyuhe bwinshi, hamwe n’imiti ihamye kugirango habeho guhuza umusaruro n’umusaruro w’ibicuruzwa.

Ibintu by'ingenzi

1. Imikorere yubushyuhe

- Ubushyuhe bwo hejuru cyane: 140–300 W / m · K, burenze cyane grafite gakondo (85 W / m · K), bituma ubushyuhe bwihuta kandi bigabanya ubushyuhe bwumuriro.

- Coefficient yo kwagura ubushyuhe buke: 4.0 × 10⁻⁶ / ℃ (25-1000 ℃), ihuza cyane na silikoni (2.6 × 10⁻⁶ / ℃), bigabanya ingaruka ziterwa no guhindura ubushyuhe.

2. Ibikoresho bya mashini

- Imbaraga Zirenze: Imbaraga zidasanzwe ≥320 MPa (20 ℃), irwanya kwikuramo n'ingaruka.

- Ubukomere Bukuru: Mohs gukomera 9.5, icya kabiri nyuma ya diyama, itanga imbaraga zo kwihanganira kwambara.

3. Imiti ihamye

- Kurwanya ruswa: Kurwanya acide zikomeye (urugero, HF, H₂SO₄), bikwiranye no gutunganya ibidukikije.

- Ntabwo ari Magnetique: Imikorere ya magnetiki yimbere <1 × 10⁻⁶ emu / g, wirinda kwivanga nibikoresho byuzuye.

4. Kwihanganira Ibidukikije Bikabije

- Ubushyuhe bwo hejuru Buramba: Ubushyuhe bwigihe kirekire bwo gukora kugeza 1600–1900 ℃; kurwanya igihe gito kugeza kuri 2200 ℃ (ibidukikije bitagira ogisijeni).

- Kurwanya Ubushyuhe bwa Thermal: Ihangane nimpinduka zubushyuhe butunguranye (ΔT> 1000 ℃) nta gucika.

Porogaramu

| Umwanya wo gusaba | Ibihe byihariye | Agaciro Tekinike |

| Gukora Semiconductor | Kureka Wafer (ICP), kubika firime yoroheje (MOCVD), gusiga CMP | Ubushyuhe bukabije butanga ubushyuhe bumwe; kwagura ubushyuhe buke bigabanya wafer warpage. |

| LED Umusaruro | Gukura kwa Epitaxial (urugero, GaN), gushushanya wafer, gupakira | Kurwanya inenge zubwoko bwinshi, kuzamura LED kumurika no kubaho. |

| Inganda zifotora | Silicon wafer gucana itanura, ibikoresho bya PECVD birashyigikira | Ubushyuhe bwo hejuru hamwe nubushyuhe bwumuriro byongera ibikoresho igihe cyose. |

| Laser & Optics | Imbaraga nyinshi za laser zo gukonjesha substrate, sisitemu ya optique ishyigikira | Amashanyarazi menshi atuma ubushyuhe bwiyongera vuba, bigahindura ibice bya optique. |

| Ibikoresho byo gusesengura | Abafite icyitegererezo cya TGA / DSC | Ubushyuhe buke hamwe nigisubizo cyihuse cyumuriro bitezimbere gupima neza. |

Gutanga Inyungu

- Imikorere yuzuye: Ubushyuhe bwumuriro, imbaraga, hamwe no kurwanya ruswa birenze kure alumina na silicon nitride ceramics, byujuje ibyifuzo bikabije.

- Igishushanyo cyoroheje: Ubucucike bwa 3.1–3.2 g / cm³ (40% byibyuma), kugabanya umutwaro udafite imbaraga no kongera icyerekezo neza.

- Kuramba & Kwizerwa: Ubuzima bwa serivisi burengeje imyaka 5 kuri 1600 ℃, kugabanya igihe cyo kugabanya no kugabanya ibiciro byakazi 30%.

- Kwiyemeza: Gushyigikira geometrike igoye (urugero, ibikombe byo guswera, ibipande byinshi) hamwe nikosa rinini <15 μm kubisobanuro byuzuye.

Ibisobanuro bya tekiniki

| Icyiciro cya Parameter | Icyerekana |

| Ibintu bifatika | |

| Ubucucike | ≥3.10 g / cm³ |

| Imbaraga zoroshye (20 ℃) | 320–410 MPa |

| Amashanyarazi (20 ℃) | 140–300 W / (m · K) |

| Coefficient yo Kwagura Ubushyuhe (25–1000 ℃) | 4.0 × 10⁻⁶ / ℃ |

| Ibikoresho bya Shimi | |

| Kurwanya Acide (HF / H₂SO₄) | Nta ruswa nyuma yo kwibizwa 24h |

| Gukora neza | |

| Kubeshya | ≤15 mm (300 × 300 mm) |

| Ubuso Bwuzuye (Ra) | ≤0.4 mm |

Serivisi za XKH

XKH itanga ibisubizo byuzuye byinganda bikubiyemo iterambere ryigenga, gutunganya neza, no kugenzura ubuziranenge bukomeye. Kugirango iterambere ryigenga, ritanga ubuziranenge (> 99,999%) hamwe nibisubizo (30-50% porosity) ibisubizo byibikoresho, bigahuzwa no kwerekana imiterere ya 3D hamwe no kwigana kugirango habeho geometrike igoye ikoreshwa nka semiconductor hamwe nindege. Gutunganya neza bikurikira inzira yoroheje: gutunganya ifu → isostatike / gukanda byumye → 2200 ° C gucumura → CNC / gusya diyama → kugenzura, kwemeza ko urwego rwa nanometero no kwihanganira mm 0.01 mm. Kugenzura ubuziranenge bikubiyemo ibizamini byuzuye (ibice bya XRD, microstructure ya SEM, kugorora amanota 3) hamwe nubufasha bwa tekiniki (gutezimbere inzira, kugisha inama 24/7, gutanga amasaha 48 y'icyitegererezo), gutanga ibice byizewe, bikora neza kugirango bikenure mu nganda.

Ibibazo Bikunze Kubazwa (Ibibazo)

1. Ikibazo: Ni izihe nganda zikoresha silicon karbide ceramic tray?

Igisubizo.

2. Ikibazo: Nigute karibide ya silicon iruta quartz / ibirahuri?

Igisubizo: Kurwanya ubushyuhe bukabije bwumuriro (kugeza 1800 ° C na 1100 ° C ya quartz), kwangiriza magnetiki zero, no kuramba (imyaka 5+ n'amezi 6-12 ya quartz).

3. Ikibazo: Inzira ya karibide ya silicon irashobora gukemura ibidukikije?

Igisubizo: Yego. Kurwanya HF, H2SO4, na NaOH hamwe na <0.01mm kwangirika / umwaka, bigatuma biba byiza mugukora imiti no gusukura wafer.

4. Ikibazo: Ese trayike ya karibide ya silicon irahuye no kwikora?

Igisubizo: Yego. Yashizweho kuri pickup ya vacuum no gukoresha robot, hamwe nuburinganire bwubuso <0.01mm kugirango wirinde kwanduza uduce muri fab zikoresha.

5. Ikibazo: Kugereranya ibiciro nibikoresho gakondo ni ibihe?

Igisubizo: Igiciro cyo hejuru (3-5x quartz) ariko 30-50% munsi ya TCO kubera igihe kinini cyo kubaho, kugabanuka kumasaha, hamwe no kuzigama ingufu ziva mumashanyarazi arenze.