SiCOI wafer 4inch 6inch HPSI SiC SiO2 Si imiterere yububiko

Imiterere ya wafer ya SiCOI

HPB. Harimo:

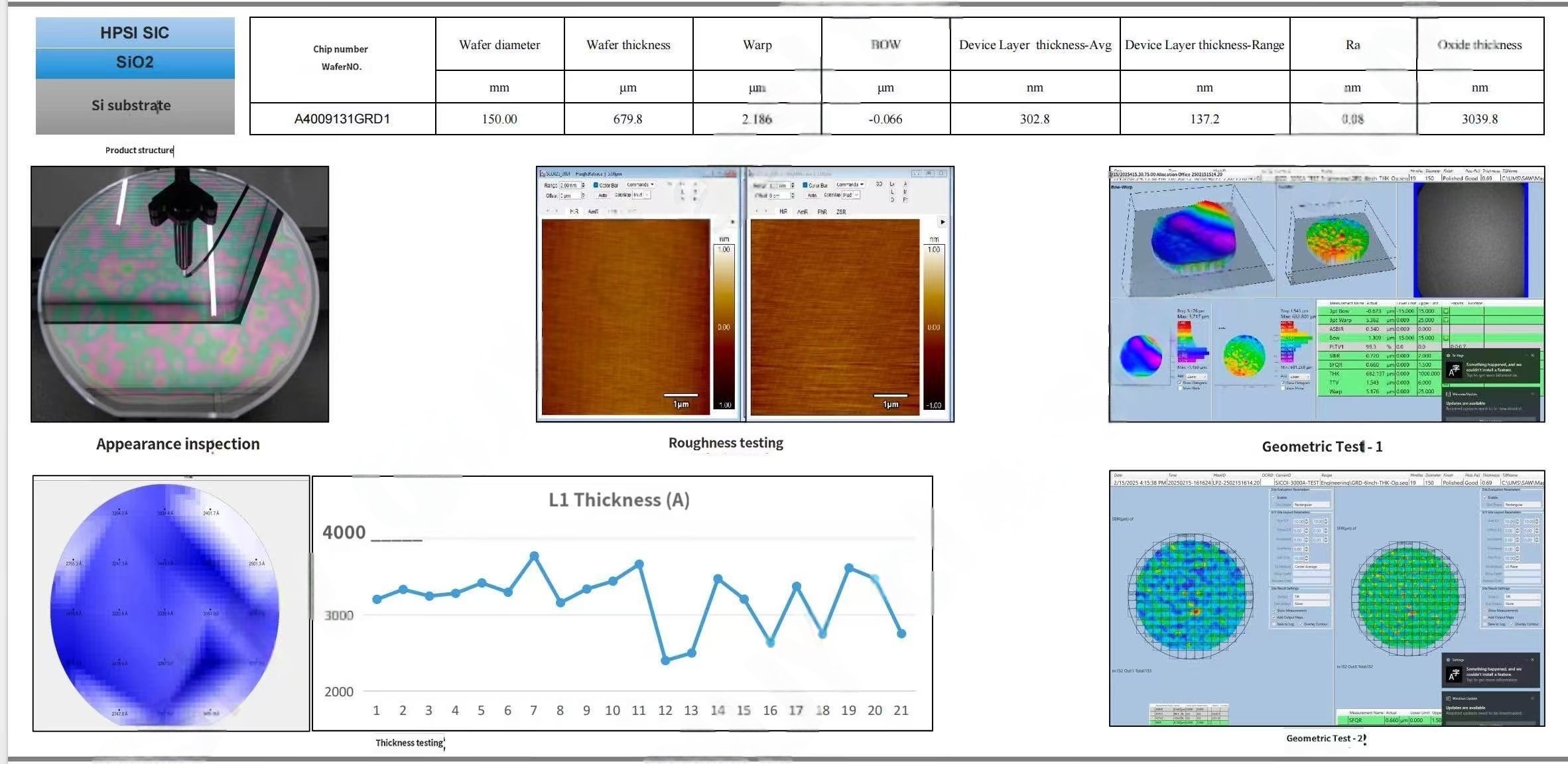

Ibipimo by'imikorere:

Urutonde rw'ibipimo nkukuri, ubwoko bwikosa (urugero, "Nta kosa," "Intera Agaciro"), hamwe no gupima uburebure (urugero, "Uburebure bwa Layeri / kg").

Imbonerahamwe ifite agaciro k'umubare (birashoboka ko igeragezwa cyangwa ibipimo byerekana) munsi y'imitwe nka "ADDR / SYGBDT," "10/0," nibindi.

Ubunini bwurwego:

Inyandiko nyinshi zisubiramo zanditseho "L1 Ubunini (A)" kugeza "L270 Ubunini (A)" (birashoboka muri Ångströms, 1 Å = 0.1 nm).

Tanga ibitekerezo byuburyo bwinshi hamwe nubugenzuzi bwuzuye bwubugenzuzi kuri buri cyiciro, gisanzwe muri waferi yateye imbere.

Imiterere ya Wafer

SiCOI (Caricon Carbide kuri Insulator) nuburyo bwihariye bwa wafer buhuza karibide ya silicon (SiC) hamwe nigice cyiziritse, gisa na SOI (Silicon-on-Insulator) ariko ikanashyirwa mubikorwa byimbaraga nyinshi / ubushyuhe bwo hejuru. Ibintu by'ingenzi:

Ibigize:

Igice cyo hejuru: Imashini imwe ya kirisiti ya Silicon Carbide (SiC) kugirango igendere hejuru ya electron hamwe nubushyuhe bwumuriro.

Imashini yashyinguwe: Mubisanzwe SiO₂ (oxyde) cyangwa diyama (muri SOD) kugirango igabanye ubushobozi bwa parasitike no kunoza kwigunga.

Base Substrate: Silicon cyangwa polycrystalline SiC kugirango ifashe imashini

Umutungo wa SiCOI wafer

Ibyiza by'amashanyarazi Umuyoboro mugari (3.2 eV kuri 4H-SiC): Gushoboza imbaraga zo kumeneka cyane (> 10 × hejuru ya silicon) .Gabanya imiyoboro yameneka, ikanoza imikorere yibikoresho byamashanyarazi.

Umuvuduko mwinshi wa elegitoronike:~ 900 cm² / V · s (4H-SiC) na ~ 1,400 cm² / V · s (Si), ariko imikorere myiza yo murwego rwo hejuru.

Kurwanya Kurwanya:Transistor ishingiye kuri SiCOI (urugero, MOSFETs) yerekana igihombo cyo gutwara.

Ubwishingizi buhebuje:Oxyde yashyinguwe (SiO₂) cyangwa diyama igabanya ubushobozi bwa parasitike hamwe na kambuka.

- Ibyiza bya ThermalUbushyuhe bwo hejuru cyane: SiC (~ 490 W / m · K kuri 4H-SiC) na Si (~ 150 W / m · K) .Diamond (niba ikoreshwa nka insulator) irashobora kurenga 2000 W / m · K, bigatuma ubushyuhe bukwirakwizwa.

Ubushyuhe bwumuriro:Ikora byizewe kuri> 300 ° C (v. ~ 150 ° C kuri silicon) .Bigabanya gukonjesha muri electronics power.

3. Ibikoresho bya mashini & imitiGukomera gukabije (~ 9.5 Mohs): Irwanya kwambara, bigatuma SiCOI iramba kubidukikije bikaze.

Ubuvuzi bwa Shimi:Irwanya okiside na ruswa, ndetse no mubihe bya acide / alkaline.

Kwiyongera k'ubushyuhe buke:Ihuza neza nibindi bikoresho byo hejuru-ubushyuhe (urugero, GaN).

4. Ibyiza byubaka (vs. Bulk SiC cyangwa SOI)

Kugabanya Igihombo cya Substrate:Gukingura ibice birinda kumeneka muri substrate.

Kunoza imikorere ya RF:Ubushobozi buke bwa parasitike butuma guhinduranya byihuse (bifite akamaro kubikoresho bya 5G / mmWave).

Igishushanyo cyoroshye:Hejuru ya SiC yo hejuru itanga uburyo bwiza bwo gupima ibikoresho (urugero, imiyoboro ya ultra-thin muri transistors).

Kugereranya na SOI & Bulk SiC

| Umutungo | SiCOI | SOI (Si / SiO₂ / Si) | Bulk SiC |

| Bandgap | 3.2 eV (SiC) | 1.1 eV (Si) | 3.2 eV (SiC) |

| Amashanyarazi | Hejuru (SiC + diyama) | Hasi (SiO₂ igabanya ubushyuhe) | Hejuru (SiC gusa) |

| Umuvuduko w'amashanyarazi | Hejuru cyane | Guciriritse | Hejuru cyane |

| Igiciro | Hejuru | Hasi | Isumbabyose (SiC yera) |

Porogaramu ya SiCOI wafer

Amashanyarazi

Wafer ya SiCOI ikoreshwa cyane mubikoresho bikoresha ingufu za semiconductor nyinshi nka MOSFETs, diode ya Schottky, hamwe nu mashanyarazi. Umuyoboro mugari hamwe na voltage yamenetse ya SiC ituma imbaraga zihinduka neza hamwe nigihombo kigabanutse kandi byongera imikorere yubushyuhe.

Ibikoresho bya Radio Frequency (RF)

Icyuma gikingira muri wafers ya SiCOI kigabanya ubushobozi bwa parasitike, bigatuma gikwirakwizwa na tristoriste yumurongo mwinshi hamwe na amplificateur zikoreshwa mu itumanaho, radar, na tekinoroji ya 5G.

Sisitemu ya Microelectromechanical (MEMS)

Wafer ya SiCOI itanga urubuga rukomeye rwo guhimba sensor ya MEMS na moteri ikora neza ahantu habi bitewe nubushakashatsi bwa SiC nimbaraga za mashini.

Ibikoresho bya elegitoroniki yo hejuru

SiCOI ituma ibikoresho bya elegitoroniki bikomeza imikorere no kwizerwa ku bushyuhe bwo hejuru, bikungukira mu binyabiziga, mu kirere, no mu nganda aho ibikoresho bya silikoni bisanzwe binanirwa.

Ibikoresho bya Photonic na Optoelectronic

Gukomatanya ibintu bya optique ya SiC hamwe na insulasiyo yorohereza guhuza imiyoboro ya fotonike hamwe nogucunga neza ubushyuhe.

Imirasire-Ikomeye ya elegitoroniki

Bitewe no kwihanganira imirasire ya SiC, wafer ya SiCOI nibyiza kumwanya hamwe nibisabwa bya kirimbuzi bisaba ibikoresho bihanganira ibidukikije bikabije.

Ikibazo cya SiCOI wafer

Q1: Wafer ya SiCOI ni iki?

Igisubizo: SiCOI igereranya Silicon Carbide-kuri-Insulator. Nuburyo bwa semiconductor wafer aho urwego ruto rwa karubide ya silicon (SiC) ihujwe kumurongo wikingira (ubusanzwe dioxyde de silicon, SiO₂), ushyigikiwe na silicon substrate. Iyi miterere ihuza ibintu byiza bya SiC hamwe no gutandukanya amashanyarazi na insulator.

Q2: Ni izihe nyungu nyamukuru za wafer ya SiCOI?

Igisubizo: Ibyiza byingenzi birimo imbaraga zo kumeneka cyane, kwaguka kwagutse, ubushyuhe bwiza bwumuriro, gukomera gukomeye, hamwe no kugabanya ubushobozi bwa parasitike tubikesha urwego rukingira. Ibi biganisha kumikorere yibikoresho, gukora neza, no kwizerwa.

Q3: Ni ubuhe buryo busanzwe bukoreshwa muri waferi ya SiCOI?

Igisubizo.

Igishushanyo kirambuye