Silicon carbide ceramic tray sucker Silicon carbide ceramic tube itanga ubushyuhe bwo hejuru bwo gucumura ibicuruzwa

Ibyingenzi byingenzi:

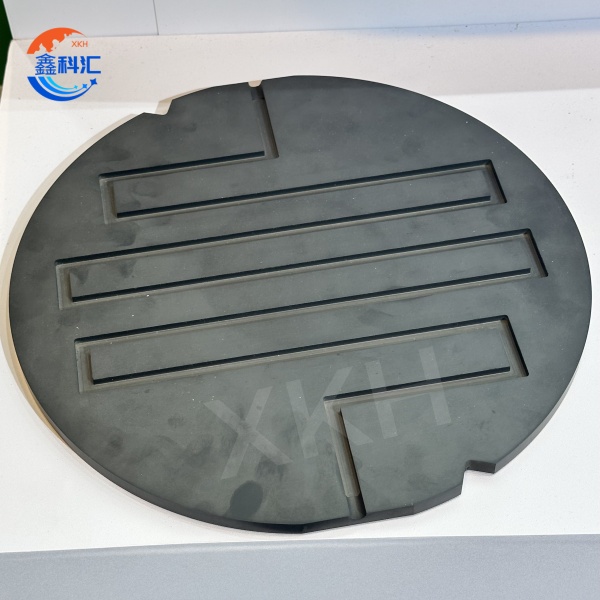

1. Silicon carbide ceramic tray

- Gukomera cyane no kwambara birwanya: ubukana buri hafi ya diyama, kandi burashobora kwihanganira imyenda ya mashini mugutunganya wafer igihe kirekire.

- Ubushyuhe bukabije bwumuriro hamwe nubushobozi buke bwo kwagura ubushyuhe: kugabanuka kwubushyuhe bwihuse hamwe no guhagarara neza, kwirinda ihinduka ryatewe nubushyuhe bwumuriro.

- Uburinganire buringaniye hamwe nubuso burangirira: Ubuso buringaniye bugera kurwego rwa micron, byemeza guhuza byuzuye hagati ya wafer na disiki, kugabanya kwanduza no kwangirika.

Imiti itajegajega: Kurwanya ruswa ikomeye, ikwiranye nogusukura amazi no gutobora mubikorwa bya semiconductor.

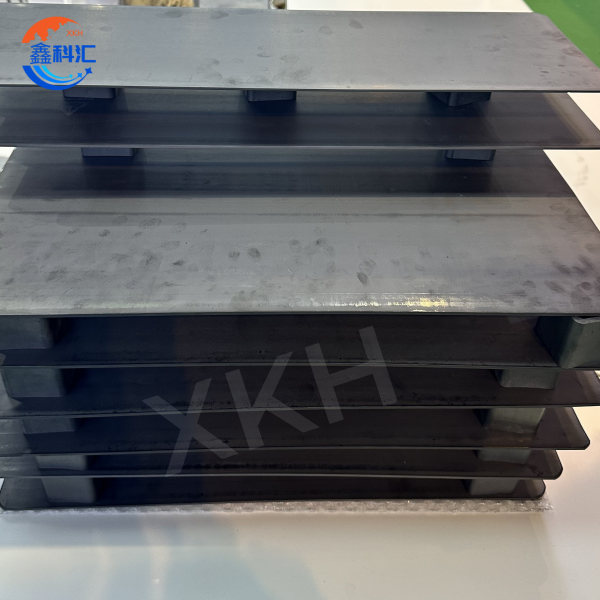

2. Silicon carbide ceramic tube

- Kurwanya ubushyuhe bwinshi: Irashobora gukora mubushyuhe bwo hejuru hejuru ya 1600 ° C mugihe kirekire, ikwiranye nubushyuhe bwo hejuru bwa semiconductor.

Kurwanya ruswa nziza cyane: irwanya aside, alkalis hamwe nudukoko twinshi twa chimique, ibereye ibidukikije bikabije.

- Gukomera cyane no kwambara birwanya: kurwanya isuri no kwambara kwa mashini, kwagura ubuzima bwa serivisi.

- Ubushyuhe bukabije bwumuriro hamwe na coefficient nkeya yo kwaguka kwubushyuhe: gutwara vuba ubushyuhe nuburinganire buringaniye, kugabanya guhindagurika cyangwa gucika biterwa nubushyuhe bwumuriro.

Ibipimo by'ibicuruzwa :

Silicon carbide ceramic tray parameter:

| (Umutungo w'ibikoresho) | (Igice) | (ssic) | |

| (Ibirimo SiC) | (Wt)% | > 99 | |

| (Impuzandengo y'ingano) | micron | 4-10 | |

| (Ubucucike) | kg / dm3 | > 3.14 | |

| (Ikigaragara ni uko) | Vo1% | <0.5 | |

| (Gukomera kwa Vickers) | HV 0.5 | GPa | 28 |

| * () Imbaraga zoroshye * (ingingo eshatu) | 20ºC | MPa | 450 |

| (Imbaraga zo guhonyora) | 20ºC | MPa | 3900 |

| (Moderi ya Elastike) | 20ºC | GPa | 420 |

| (Gukomera kuvunika) | MPa / m '% | 3.5 | |

| (Ubushyuhe bwa Thermal) | 20 ° ºC | W / (m * K) | 160 |

| (Kurwanya) | 20 ° ºC | Ohm.cm | 106-108 |

(Coefficient yo kwagura ubushyuhe) | a (RT ** ... 80ºC) | K-1 * 10-6 | 4.3 |

(Ubushyuhe ntarengwa bwo gukora) | oºC | 1700 | |

Silicon carbide ceramic tube parameter:

| Ibintu | Ironderero |

| α-SIC | 99% min |

| Ikigaragara | 16% max |

| Ubucucike bwinshi | 2.7g / cm3 min |

| Imbaraga Zunamye ku bushyuhe bwo hejuru | 100 Mpa min |

| Coefficient yo Kwagura Ubushyuhe | K-1 4.7x10 -6 |

| Coefficient yubushyuhe bwumuriro (1400ºC) | 24 W / mk |

| Icyiza. Ubushyuhe bwo gukora | 1650ºC |

Porogaramu nyamukuru:

1. Isahani ya silicon karbide

- Gukata Wafer no gusya: ikora nk'urubuga rwo gutwara kugirango habeho neza kandi neza mugihe cyo gukata no gusya.

- Uburyo bwa Lithographie: Wafer yashyizwe mumashini ya lithographie kugirango ihagarare neza neza mugihe cyo kwerekana.

- Imashini ikora imashini (CMP): ikora nk'urubuga rushyigikira amashanyarazi, rutanga igitutu kimwe no gukwirakwiza ubushyuhe.

2. Silicon carbide ceramic tube

- Itanura ryubushyuhe bwo hejuru: rikoreshwa mubikoresho byubushyuhe bwo hejuru nkitanura rya diffusion hamwe nitanura rya okiside kugirango bitware wafer kugirango bivure ubushyuhe bwinshi.

- Inzira ya CVD / PVD: Nka tariyeri itwara icyumba cya reaction, irwanya ubushyuhe bwinshi na gaze yangirika.

- Ibikoresho bya Semiconductor ibikoresho: kubihinduranya ubushyuhe, imiyoboro ya gaze, nibindi, kugirango tunoze imikorere yubushyuhe bwibikoresho.

XKH itanga serivisi zuzuye kubikorwa bya silicon karbide ceramic tray, ibikombe byo guswera hamwe na silicon carbide ceramic tubes. Silicon carbide ceramic tray hamwe nigikombe cyokunywa, XKH irashobora guhindurwa ukurikije ibyo umukiriya asabwa mubunini butandukanye, imiterere nubuso butandukanye, kandi agashyigikira uburyo bwihariye bwo kuvura, kongera imbaraga zo kurwanya no kwangirika; Kuri silicon carbide ceramic tubes, XKH irashobora gutandukanya diameter zitandukanye zimbere, diameter yinyuma, uburebure nuburyo bugoye (nkumuyoboro wubatswe cyangwa umuyoboro wuzuye), kandi bigatanga polishing, anti-okiside hamwe nubundi buryo bwo kuvura hejuru. X.

Igishushanyo kirambuye