SiO₂ Quartz Wafer Quartz Wafers SiO₂ MEMS Ubushyuhe 2 ″ 3 ″ 4 ″ 6 ″ 8 ″ 12 ″

Igishushanyo kirambuye

Intangiriro

Wafers ya Quartz igira uruhare rukomeye mugutezimbere ibikoresho bya elegitoroniki, semiconductor, na optique. Biboneka muri terefone zigendanwa ziyobora GPS yawe, yinjijwe muri sitasiyo yumurongo wibanze ikoresha imiyoboro ya 5G, kandi ikinjizwa mubikoresho bikora mikorobe ikurikira-gen, wafers ya quartz ni ngombwa. Izi ntera-isukuye cyane ituma habaho udushya muri byose kuva kuri comptabilite kugeza kuri fotonike igezweho. Nubwo yakomotse kuri imwe mu mabuye y'agaciro menshi ku isi, wafer ya quartz ikorwa ku bipimo bidasanzwe byerekana neza imikorere.

Niki Quartz Wafers

Wafers ya Quartz iroroshye, disiki zizunguruka zakozwe muri ultra-pure synthique ya quartz kristal. Biboneka mubipimo bisanzwe biri hagati ya santimetero 2 na 12, wafer ya quartz mubusanzwe ifite uburebure kuva kuri mm 0,5 kugeza kuri mm 6. Bitandukanye na quartz karemano, ikora kristu idasanzwe idasanzwe, quartz ya syntetique ikura mugihe cya laboratoire igenzurwa cyane, ikabyara kristu imwe.

Ikirangantego kavukire cya quartz wafers itanga imiti itagereranywa irwanya imiti, gukorera mu mucyo, no gutuza munsi yubushyuhe bwinshi hamwe na stress ya mashini. Ibiranga bituma quartz wafers igizwe nishingiro ryibikoresho bisobanutse bikoreshwa mugukwirakwiza amakuru, kumva, kubara, hamwe nikoranabuhanga rishingiye kuri laser.

Ibisobanuro bya Quartz Wafer

| Ubwoko bwa Quartz | 4 | 6 | 8 | 12 |

|---|---|---|---|---|

| Ingano | ||||

| Diameter (santimetero) | 4 | 6 | 8 | 12 |

| Umubyimba (mm) | 0.05-2 | 0.25–5 | 0.3–5 | 0.4-5 |

| Kwihanganira Diameter (santimetero) | ± 0.1 | ± 0.1 | ± 0.1 | ± 0.1 |

| Ubworoherane bwimbitse (mm) | Guhindura | Guhindura | Guhindura | Guhindura |

| Ibyiza | ||||

| Igipimo cyerekana @ 365 nm | 1.474698 | 1.474698 | 1.474698 | 1.474698 |

| Igipimo cyerekana @ 546.1 nm | 1.460243 | 1.460243 | 1.460243 | 1.460243 |

| Ironderero ryerekana @ 1014 nm | 1.450423 | 1.450423 | 1.450423 | 1.450423 |

| Kohereza imbere (1250–1650 nm) | > 99.9% | > 99.9% | > 99.9% | > 99.9% |

| Amafaranga yose yoherejwe (1250–1650 nm) | > 92% | > 92% | > 92% | > 92% |

| Imashini nziza | ||||

| TTV (Gutandukana kwinshi, µm) | <3 | <3 | <3 | <3 |

| Kureshya (µm) | ≤15 | ≤15 | ≤15 | ≤15 |

| Ubuso bwubuso (nm) | ≤1 | ≤1 | ≤1 | ≤1 |

| Umuheto (µm) | <5 | <5 | <5 | <5 |

| Ibintu bifatika | ||||

| Ubucucike (g / cm³) | 2.20 | 2.20 | 2.20 | 2.20 |

| Modulus yumusore (GPa) | 74.20 | 74.20 | 74.20 | 74.20 |

| Mohs Gukomera | 6-7 | 6-7 | 6-7 | 6-7 |

| Shear Modulus (GPa) | 31.22 | 31.22 | 31.22 | 31.22 |

| Ikigereranyo cya Poisson | 0.17 | 0.17 | 0.17 | 0.17 |

| Imbaraga Zikomeretsa (GPa) | 1.13 | 1.13 | 1.13 | 1.13 |

| Imbaraga za Tensile (MPa) | 49 | 49 | 49 | 49 |

| Umuyoboro wa Dielectric (1 MHz) | 3.75 | 3.75 | 3.75 | 3.75 |

| Ibyiza bya Thermal | ||||

| Ingingo ya Strain (10¹⁴.⁵ Pa · s) | 1000 ° C. | 1000 ° C. | 1000 ° C. | 1000 ° C. |

| Ingingo ya Annealing (10¹³ Pa · s) | 1160 ° C. | 1160 ° C. | 1160 ° C. | 1160 ° C. |

| Ingingo yoroshye (10⁷.⁶ Pa · s) | 1620 ° C. | 1620 ° C. | 1620 ° C. | 1620 ° C. |

Porogaramu ya Quartz Wafers

Wafers ya Quartz ikozwe neza kugirango ihuze ibyifuzo bisabwa mu nganda zirimo:

Ibikoresho bya elegitoroniki n'ibikoresho bya RF

- Wafers ya Quartz nibyingenzi kuri quartz kristal resonator hamwe na oscillator zitanga ibimenyetso byamasaha ya terefone igendanwa, ibice bya GPS, mudasobwa, nibikoresho byitumanaho bidafite umugozi.

- Kwiyongera kwinshi kwubushyuhe hamwe na Q-ibintu byinshi bituma quartz wafers itunganijwe neza kumurongo wigihe gihamye cyumuzunguruko hamwe na RF muyunguruzi.

Optoelectronics hamwe no Kwerekana

- Wafers ya Quartz itanga uburyo bwiza bwo kohereza UV na IR, bigatuma biba byiza kuri lens optique, gutandukanya ibiti, amadirishya ya laser, na detector.

- Kurwanya imirasire bifasha gukoresha muri fiziki yingufu nyinshi nibikoresho byo mu kirere.

Semiconductor na MEMS

- Wafers ya Quartz ikora nka substrate yumuzunguruko mwinshi wa semiconductor, cyane cyane muri GaN na RF.

- Muri MEMS (Micro-Electro-Mechanical Systems), wafers ya quartz ihindura ibimenyetso bya mashini mubyuma byamashanyarazi binyuze mumashanyarazi ya piezoelectric, bigafasha sensor nka giroskopi na moteri yihuta.

Iterambere ryambere & Laboratwari

- Wafers zifite isuku nyinshi zikoreshwa cyane muri laboratoire ya chimique, biomedical, na fotonike ya selile optique, UV cuvettes, hamwe nicyitegererezo cyo hejuru.

- Guhuza kwabo nibidukikije bikabije bituma bibera ibyumba bya plasma nibikoresho byo kubitsa.

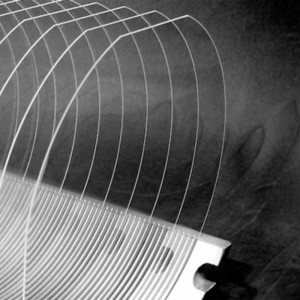

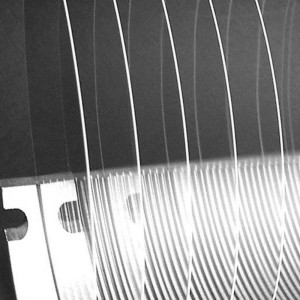

Ukuntu Quartz Wafers Yakozwe

Hariho inzira ebyiri zibanze zo gukora kuri wafers ya quartz:

Ikoreshwa rya Quartz Wafers

Wafers ya quartz yahujwe ikozwe mugushonga granules karemano mubirahuri bya amorphous, hanyuma ugakata hanyuma ugahanagura ikibanza gikomeye mo wafer. Wafers ya quartz itanga:

- UV idasanzwe

- Ikoreshwa ryinshi ryumuriro (> 1100 ° C)

- Kurwanya ubushyuhe bwiza cyane

Nibyiza kubikoresho bya lithographie, itanura ryubushyuhe bwo hejuru, hamwe na windows optique ariko ntibikwiriye gukoreshwa na piezoelectric kubera kubura gahunda ya kristu.

Umuco wa Quartz Wafers

Wafers yumuco ikuze ikura muburyo bwo kubyara kristu idafite inenge hamwe nicyerekezo cya lattice. Iyi wafer yakozwe mubisabwa bisaba:

- Inguni zikata neza (X-, Y-, Z-, AT-gukata, nibindi)

- Umuvuduko mwinshi-oscillator hamwe na SAW muyunguruzi

- Optical polarizers nibikoresho bya MEMS bigezweho

Igikorwa cyo kubyaza umusaruro kirimo gukura kwimbuto muri autoclave, hagakurikiraho gukata, icyerekezo, guhuza, no gusya.

Abayobora Quartz Wafer

Abatanga isoko ryinzobere muri quartz wafers yuzuye neza harimo:

- Heraeus(Ubudage) - quartz yahujwe na synthique

- Shin-Etsu Quartz(Ubuyapani) - igisubizo cya wafer-cyera cyane

- WaferPro(USA) - diameter yagutse ya quartz wafers hamwe na substrate

- Korth Kristalle(Ubudage) - waferi yubukorikori

Uruhare rwiterambere rwa Quartz Wafers

Wafers ya Quartz ikomeje kugenda ihinduka nkibice byingenzi mubijyanye na tekinoroji igaragara:

- Miniaturisation- Wafers ya Quartz irimo guhimbwa hamwe no kwihanganira cyane kugirango ibikoresho byinjizwe.

- Ibyuma bya elegitoroniki Byinshi- Ibishushanyo bishya bya quartz wafer birasunika muri mmWave na THz kuri 6G na radar.

- Ibikurikira-Gen- Kuva ku binyabiziga byigenga kugera mu nganda IoT, ibyuma bishingiye kuri quartz bigenda biba ngombwa.

Ibibazo bikunze kubazwa kubyerekeranye na quartz wafers

1. Wafer ni iki?

Wafer ya quartz ni disiki yoroheje, iringaniye ikozwe muri dioxyde ya silicon silicon (SiO₂), ubusanzwe ikorwa mubunini bwa semiconductor (urugero, 2 ", 3", 4 ", 6", 8 ", cyangwa 12"). Azwiho kuba ifite isuku ryinshi, ituje ryumuriro, hamwe na optique ibonerana, wafer ya quartz ikoreshwa nka substrate cyangwa umutwara mubikorwa bitandukanye bisobanutse neza nko guhimba semiconductor, ibikoresho bya MEMS, sisitemu ya optique, hamwe na vacuum.

2. Ni irihe tandukaniro riri hagati ya quartz na silika gel?

Quartz nuburyo bukomeye bwa kirisiti ya dioxyde ya silicon (SiO₂), mugihe gelika ya silika nuburyo bwa amorphous kandi bworoshye bwa SiO₂, bukunze gukoreshwa nkibikoresho byo gukuramo amazi.

- Quartz irakomeye, iragaragara, kandi ikoreshwa mubikoresho bya elegitoroniki, optique, ninganda.

- Silika gel igaragara nkamasaro mato cyangwa granules kandi ikoreshwa cyane cyane mukugenzura ubuhehere mubipfunyika, ibikoresho bya elegitoroniki, nububiko.

3. Ni ikihe kirisiti ya quartz ikoreshwa?

Kirisiti ya Quartz ikoreshwa cyane muri electronics na optique kubera imiterere ya piezoelectric (itanga amashanyarazi mumashanyarazi). Porogaramu zisanzwe zirimo:

- Oscillator hamwe no kugenzura inshuro(urugero, amasaha ya quartz, amasaha, microcontrollers)

- Ibikoresho byiza(urugero, lens, plaque, Windows)

- Ibisubizo hamwe na Muyunguruzimuri RF n'ibikoresho by'itumanaho

- Sensorskubitutu, kwihuta, cyangwa imbaraga

- Guhimba Semiconductornka substrate cyangwa gutunganya Windows

4. Kuki quartz ikoreshwa muri microchips?

Quartz ikoreshwa muri porogaramu zijyanye na microchip kuko itanga:

- Ubushyuhe bukabijemugihe cy'ubushyuhe bwo hejuru nko gukwirakwiza no gufatira hamwe

- Amashanyarazikubera imiterere ya dielectric

- Kurwanya imitikuri acide na solvents zikoreshwa muguhimba semiconductor

- Ibipimo bifatikano kwaguka kwinshi kubushyuhe bwo kwizerwa kwa lithographie

- Mugihe quartz ubwayo idakoreshwa nkibikoresho bikora bya semiconductor (nka silikoni), bigira uruhare runini mubidukikije, cyane cyane mu itanura, ibyumba, hamwe na fotomask.

Ibyerekeye Twebwe

XKH kabuhariwe mu iterambere ry’ikoranabuhanga rikomeye, gukora, no kugurisha ibirahuri bidasanzwe bya optique hamwe nibikoresho bishya bya kristu. Ibicuruzwa byacu bitanga ibikoresho bya elegitoroniki, ibikoresho bya elegitoroniki, n'abasirikare. Dutanga ibice bya optique ya optique, igifuniko cya terefone igendanwa, Ceramics, LT, Silicon Carbide SIC, Quartz, hamwe na semiconductor kristal wafers. Hamwe n'ubuhanga buhanga hamwe nibikoresho bigezweho, turi indashyikirwa mugutunganya ibicuruzwa bitari bisanzwe, tugamije kuba ibikoresho bya optoelectronic ibikoresho byubuhanga buhanitse.