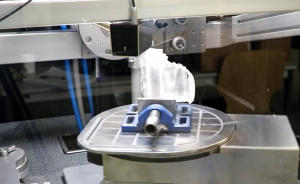

Sisitemu ya Wafer Icyerekezo cyo gupima Crystal Icyerekezo

Ibikoresho Intangiriro

Ibikoresho bya Wafer ni ibikoresho byuzuye bishingiye ku mahame ya X-ray (XRD), bikoreshwa cyane cyane mu gukora igice cya kabiri, ibikoresho bya optique, ububumbyi, n’inganda zikora ibintu bya kristu.

Ibi bikoresho bigena icyerekezo cya kristu yerekana kandi ikayobora neza gukata cyangwa gusya. Ibyingenzi byingenzi birimo:

- Ibipimo bisobanutse neza:Irashoboye gukemura indege ya kristu yerekana imyanzuro igera kuri 0.001 °.

- Icyitegererezo kinini cyo guhuza:Gushyigikira wafer igera kuri mm 450 z'umurambararo n'uburemere bwa kg 30, ibereye ibikoresho nka karubide ya silicon (SiC), safiro, na silikoni (Si).

- Igishushanyo mbonera:Ibikorwa byagutse birimo gusesengura umurongo, gusesengura ikarita ya 3D igaragara, hamwe nibikoresho byo gutondekanya byinshi.

Ibipimo byingenzi bya tekiniki

| Icyiciro cya Parameter | Indangagaciro zisanzwe / Iboneza |

| X-ray Inkomoko | Cu-Kα (0.4 × 1 mm yibanze), 30 kV yihuta ya voltage, 0-5 mA imiyoboro ihindagurika |

| Urwego | θ: -10 ° kugeza kuri + 50 °; 2θ: -10 ° kugeza + 100 ° |

| Ukuri | Inguni ihanamye: 0.001 °, gutahura inenge yo hejuru: ± 30 arcseconds (umurongo utigita) |

| Umuvuduko wo Gusikana | Omega scan irangiza icyerekezo cya lattice mumasegonda 5; Gusikana bifata ~ umunota 1 |

| Icyiciro Icyitegererezo | V-groove, guswera pneumatike, kuzenguruka impande nyinshi, guhuza na waferi ya santimetero 2-8 |

| Imikorere yagutse | Isesengura ry'umurongo uteganijwe, ikarita ya 3D, igikoresho cyo guteranya, gutahura inenge ya optique (gushushanya, GBs) |

Ihame ry'akazi

1. Fondasiyo ya X-ray

- X-imirasire ikorana na nuclei ya atome na electron muri kasitori ya kirisiti, ikabyara uburyo bwo gutandukana. Amategeko ya Bragg (nλ = 2d sinθ) agenga isano iri hagati yimfuruka (θ) nu mwanya wa latike (d).

Abashakashatsi bafata ubu buryo, bwasesenguwe kugirango hubakwe imiterere ya kristu.

2. Ikoranabuhanga rya Omega

- Kirisiti izunguruka ikomeza umurongo uhamye mugihe X-imirasire imurika.

- Detector ikusanya ibimenyetso bitandukanya indege nyinshi za kristu, zifasha kugena icyerekezo cyuzuye mumasegonda 5.

3. Gusesengura umurongo uhetamye

- Inguni ihamye ya kristu ifite impande zinyuranye za X-ray kugirango bapime ubugari bwimpinga (FWHM), gusuzuma inenge ya lattice.

4. Igenzura ryikora

- Imigaragarire ya PLC hamwe na ecran ya ecran ituma ibice byogukata mbere, ibitekerezo-nyabyo, hamwe no guhuza imashini zo gukata zifunze-kugenzura.

Ibyiza n'ibiranga

1. Gusobanura neza no gukora neza

- Ingero zifatika ± 0.001 °, gukemura inenge <30 arcseconds.

- Omega scan yihuta ni 200 × byihuse kuruta Theta scan ya gakondo.

2. Modularity and Scalability

- Kwaguka kubikorwa byihariye (urugero, waC ya SiC, ibyuma bya turbine).

- Ihuza na sisitemu ya MES yo kugenzura umusaruro-mugihe.

3. Guhuza no Guhagarara

- Yakira ingero zidasanzwe (urugero, ingofero ya safiro yamenetse).

- Igishushanyo gikonjesha ikirere kigabanya ibikenerwa byo kubungabunga.

4. Igikorwa cyubwenge

- Kanda rimwe kalibrasi no gutunganya imirimo myinshi.

- Auto-calibration hamwe na kristu yerekana kugirango ugabanye amakosa yabantu.

Porogaramu

1. Gukora Semiconductor

- Icyerekezo cyo gushushanya cya Wafer: Kugena icyerekezo cya Si, SiC, GaN icyerekezo cyo gukata neza.

- Gushushanya neza: Kugaragaza ibishushanyo mbonera cyangwa gutandukana kugirango umusaruro wa chip wiyongere.

2. Ibikoresho byiza

- Kirisiti idafite umurongo (urugero, LBO, BBO) kubikoresho bya laser.

- Safiro wafer yerekana ubuso buranga LED substrate.

3. Ubukorikori hamwe nibigize

- Gusesengura icyerekezo cy'ingano muri Si3N4 na ZrO2 kubushyuhe bwo hejuru.

4. Ubushakashatsi no kugenzura ubuziranenge

- Kaminuza / laboratoire yo gutezimbere ibintu bishya (urugero, allopy alloys).

- Inganda QC kugirango ibyiciro bihamye.

Serivisi za XKH

X. Ibisubizo byabugenewe (urugero, tekinoroji yo gutondekanya ingot) bitangwa kugirango hongerwe igice cya semiconductor hamwe nibikoresho byiza byo gukora neza hejuru ya 30%. Itsinda ryabigenewe rikora imyitozo kurubuga, mugihe 24/7 inkunga ya kure hamwe no gusimbuza igice cyihuse byemeza ibikoresho byizewe.