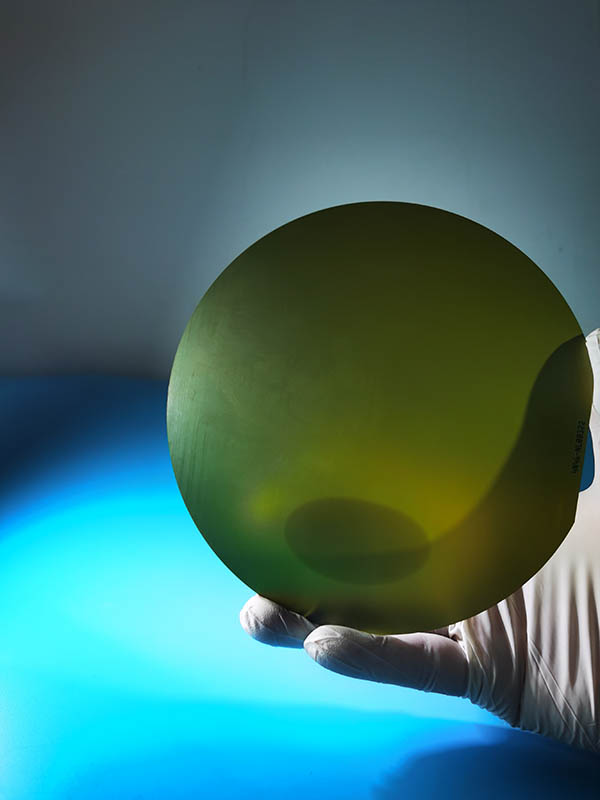

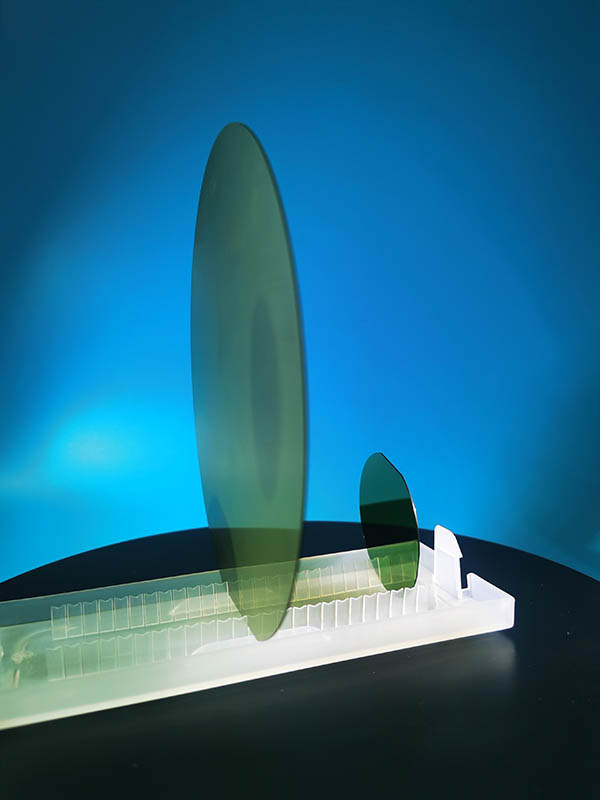

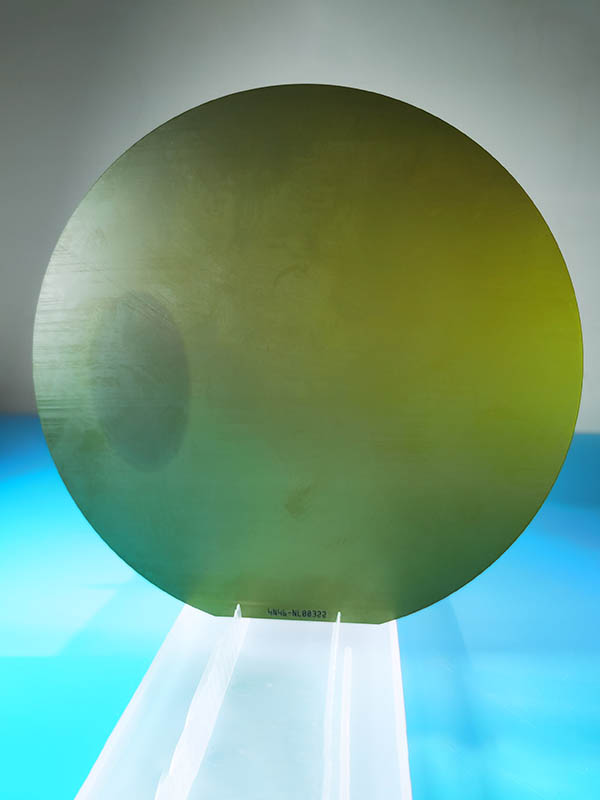

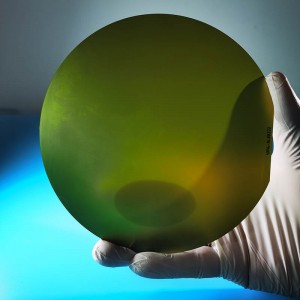

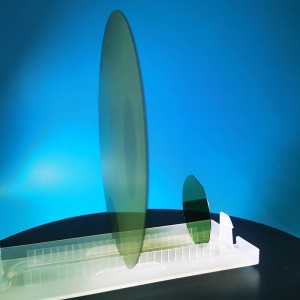

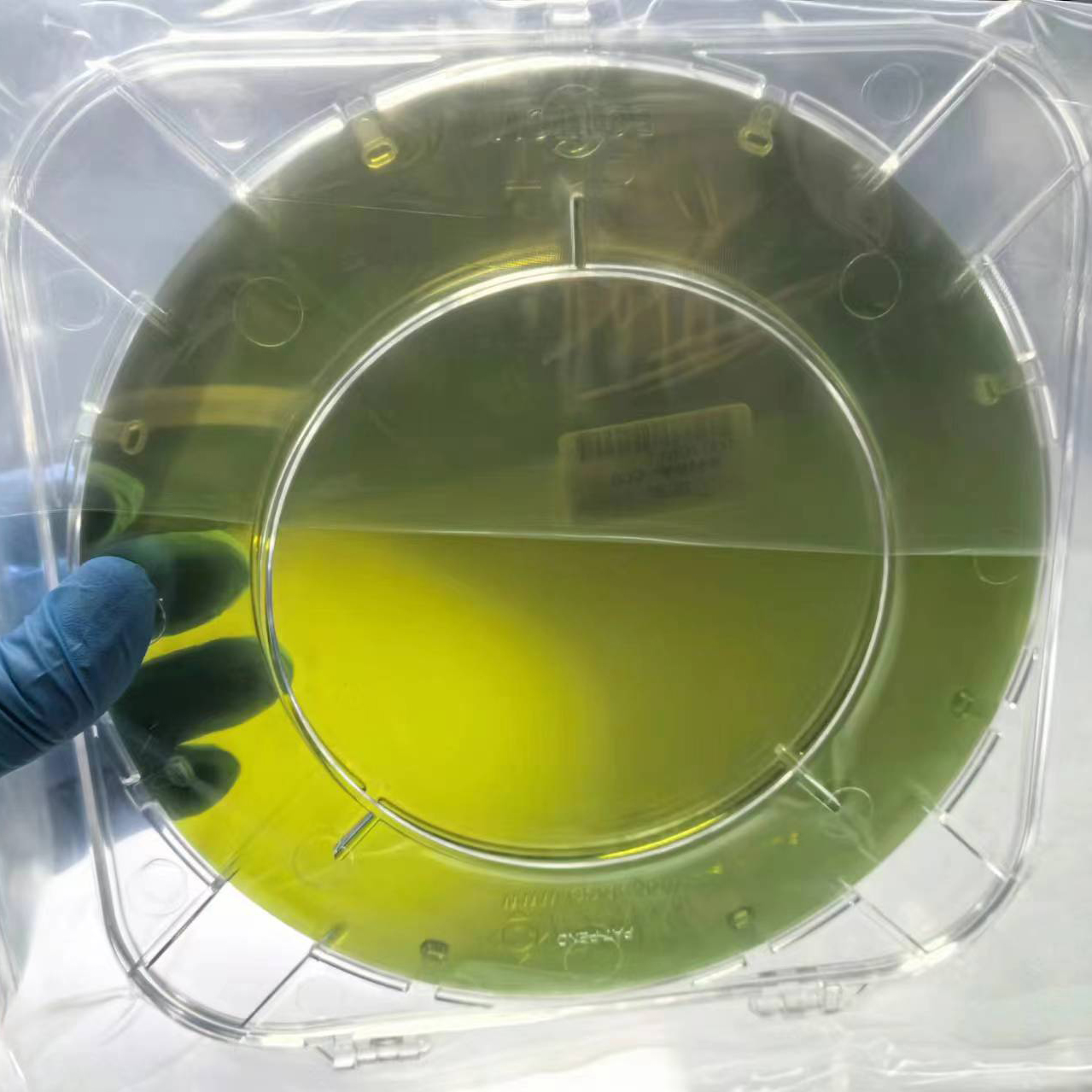

8Mu 200mm 4H-N SiC Wafer Ikora dummy icyiciro cyubushakashatsi

Bitewe nimiterere yihariye yumubiri na elegitoronike, ibikoresho bya 200mm ya SiC wafer ya semiconductor ikoreshwa mugukora ibintu byinshi, ubushyuhe bwinshi, birwanya imirasire, hamwe nibikoresho bya elegitoroniki byihuta. 8inch SiC substrate igiciro kigenda kigabanuka buhoro buhoro uko ikoranabuhanga rigenda ritera imbere kandi ibyifuzo biriyongera. Iterambere rya tekinoloji ya vuba riganisha ku musaruro wakozwe na 200mm ya SiC wafers. Ibyiza byingenzi byibikoresho bya SiC wafer ugereranije na wafers ya Si na GaAs: Imbaraga zumuriro wamashanyarazi wa 4H-SiC mugihe cyo gusenyuka kwa avalanche birenze gahunda yubunini burenze agaciro kangana na Si na GaAs. Ibi biganisha ku kugabanuka gukabije kuri leta irwanya Ron. Ubushobozi buke kuri leta, bufatanije nubucucike buri hejuru hamwe nubushyuhe bwumuriro, butuma ikoreshwa ryurupfu ruto cyane kubikoresho byamashanyarazi. Ubushyuhe bwo hejuru bwa SiC bugabanya ubukana bwumuriro wa chip. Ibikoresho bya elegitoroniki yibikoresho bishingiye kuri waferi ya SiC birahagaze neza mugihe ndetse no ku bushyuhe buhamye, ibyo bigatuma ibicuruzwa byizerwa cyane. Carbide ya Silicon irwanya cyane imirasire ikomeye, idatesha agaciro ibikoresho bya elegitoroniki ya chip. Ubushyuhe buke bugabanya ubushyuhe bwa kristu (irenga 6000C) igufasha gukora ibikoresho byizewe cyane kubikorwa bikarishye hamwe nibisabwa bidasanzwe. Kugeza ubu, turashobora gutanga ibyiciro bito 200mmSiC wafer ihamye kandi ubudahwema kandi dufite ububiko mububiko.

Ibisobanuro

| Umubare | Ingingo | Igice | Umusaruro | Ubushakashatsi | Dummy |

| 1. Ibipimo | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | Icyerekezo | ° | <11-20> 4 ± 0.5 | <11-20> 4 ± 0.5 | <11-20> 4 ± 0.5 |

| 2. Ibikoresho by'amashanyarazi | |||||

| 2.1 | dopant | -- | Ubwoko bwa Azote | Ubwoko bwa Azote | Ubwoko bwa Azote |

| 2.2 | Kurwanya | ohm · cm | 0.015 ~ 0.025 | 0.01 ~ 0.03 | NA |

| 3. Ibikoresho bya mashini | |||||

| 3.1 | diameter | mm | 200 ± 0.2 | 200 ± 0.2 | 200 ± 0.2 |

| 3.2 | ubunini | μm | 500 ± 25 | 500 ± 25 | 500 ± 25 |

| 3.3 | Icyerekezo | ° | [1- 100] ± 5 | [1- 100] ± 5 | [1- 100] ± 5 |

| 3.4 | Uburebure bwimbitse | mm | 1 ~ 1.5 | 1 ~ 1.5 | 1 ~ 1.5 |

| 3.5 | LTV | μm | ≤5 (10mm * 10mm) | ≤5 (10mm * 10mm) | ≤10 (10mm * 10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Umuheto | μm | -25 ~ 25 | -45 ~ 45 | -65 ~ 65 |

| 3.8 | Intambara | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Imiterere | |||||

| 4.1 | Ubucucike bwa micropipe | ea / cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | ibyuma | atom / cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ea / cm2 | 00500 | 0001000 | NA |

| 4.4 | BPD | ea / cm2 | 0002000 | 0005000 | NA |

| 4.5 | TED | ea / cm2 | 0007000 | 0010000 | NA |

| 5. Ubwiza bwiza | |||||

| 5.1 | imbere | -- | Si | Si | Si |

| 5.2 | Kurangiza | -- | Si-face CMP | Si-face CMP | Si-face CMP |

| 5.3 | agace | ea / wafer | ≤100 (ubunini≥0.3μm) | NA | NA |

| 5.4 | gushushanya | ea / wafer | ≤5, Uburebure bwose200mm | NA | NA |

| 5.5 | Impande chips / indents / ibice / ikizinga / kwanduza | -- | Nta na kimwe | Nta na kimwe | NA |

| 5.6 | Agace ka polytype | -- | Nta na kimwe | Ubuso ≤10% | Ubuso ≤30% |

| 5.7 | Ikimenyetso cy'imbere | -- | Nta na kimwe | Nta na kimwe | Nta na kimwe |

| 6. Ubwiza bwinyuma | |||||

| 6.1 | inyuma kurangiza | -- | Umudepite | Umudepite | Umudepite |

| 6.2 | gushushanya | mm | NA | NA | NA |

| 6.3 | Inyuma yinyuma chip / indents | -- | Nta na kimwe | Nta na kimwe | NA |

| 6.4 | Inyuma yinyuma | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Ikimenyetso cyinyuma | -- | Ikimenyetso | Ikimenyetso | Ikimenyetso |

| 7. Impande | |||||

| 7.1 | inkombe | -- | Chamfer | Chamfer | Chamfer |

| 8. Ipaki | |||||

| 8.1 | gupakira | -- | Epi-yiteguye hamwe na vacuum gupakira | Epi-yiteguye hamwe na vacuum gupakira | Epi-yiteguye hamwe na vacuum gupakira |

| 8.2 | gupakira | -- | Multi-wafer gupakira | Multi-wafer gupakira | Multi-wafer gupakira |

Igishushanyo kirambuye