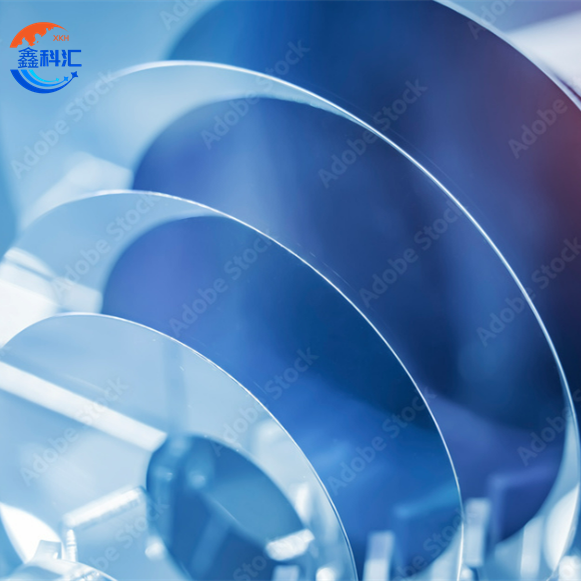

HPSI SiCOI wafer 4 6inch Guhuza Hydropholike

SiCOI Wafer (Caricon Carbide-on-Insulator) Incamake yumutungo

Wafers ya SiCOI nigisekuru gishya cya semiconductor substrate ihuza Silicon Carbide (SiC) hamwe nicyuma gikingira, akenshi SiO₂ cyangwa safiro, kugirango tunoze imikorere mubyuma bya elegitoroniki, RF, na fotonike. Hano haribisobanuro birambuye kumitungo yabo yashyizwe mubice byingenzi:

| Umutungo | Ibisobanuro |

| Ibikoresho | Silicon Carbide (SiC) igizwe na substrate ikingira (mubisanzwe SiO₂ cyangwa safiro) |

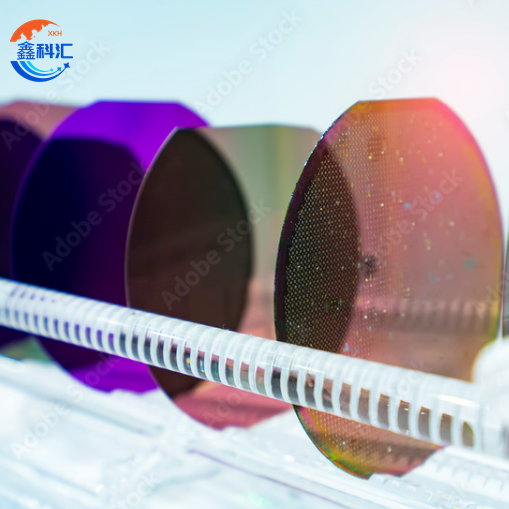

| Imiterere ya Crystal | Mubisanzwe 4H cyangwa 6H polytypes ya SiC, izwiho ubuziranenge bwa kirisiti hamwe nuburinganire |

| Ibyiza by'amashanyarazi | Umuriro w'amashanyarazi mwinshi (~ 3 MV / cm), umurongo mugari (~ 3.26 eV kuri 4H-SiC), umuyoboro muke |

| Amashanyarazi | Ubushyuhe bwinshi (~ 300 W / m · K), butuma ubushyuhe bukwirakwizwa neza |

| Inzira ya Dielectric | Gukingura ibice (SiO₂ cyangwa safiro) bitanga amashanyarazi kandi bigabanya ubushobozi bwa parasitike |

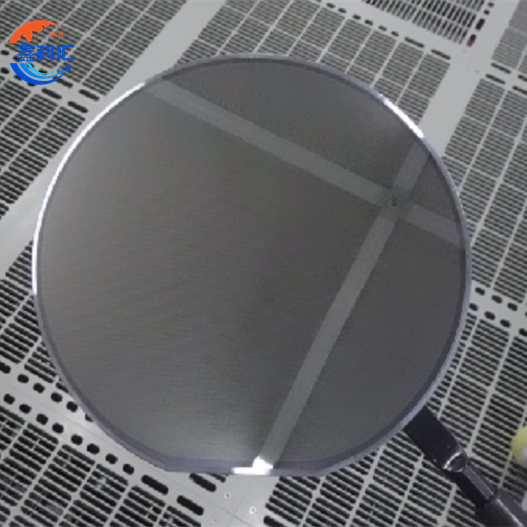

| Ibikoresho bya mashini | Gukomera cyane (~ 9 Mohs igipimo), imbaraga zumukanishi nziza, hamwe nubushyuhe bwumuriro |

| Kurangiza | Mubisanzwe ultra-yoroshye hamwe nubucucike buke, bubereye guhimba ibikoresho |

| Porogaramu | Imbaraga za elegitoroniki, ibikoresho bya MEMS, ibikoresho bya RF, sensor bisaba ubushyuhe bwinshi no kwihanganira voltage |

Wafer ya SiCOI (Silicon Carbide-on-Insulator) igereranya imiterere ya semiconductor substrate yubatswe, igizwe nurwego rwohejuru rwiza cyane rwa karubide ya silicon (SiC) ihujwe kumurongo wikingira, mubisanzwe dioxyde de silicon (SiO₂) cyangwa safiro. Carbide ya Silicon ni nini-nini ya semiconductor izwiho ubushobozi bwo guhangana n’umuvuduko mwinshi hamwe nubushyuhe bwo hejuru, hamwe nubushuhe buhebuje bwumuriro hamwe nubukomezi bukomeye bwa mashini, bigatuma biba byiza mumashanyarazi menshi, yumurongo mwinshi, hamwe nubushyuhe bwo hejuru bwa elegitoronike.

Icyuma gikingira muri wafers ya SiCOI gitanga amashanyarazi meza, kugabanya cyane ubushobozi bwa parasitike hamwe ningaruka ziva hagati yibikoresho, bityo bikazamura imikorere yibikoresho muri rusange. Ubuso bwa wafer buringaniye neza kugirango bugere kuri ultra-yoroshye hamwe nudusembwa duto, byujuje ibyifuzo bikenerwa na mikoro na nano-nini yo guhimba ibikoresho.

Imiterere yibikoresho ntabwo itezimbere gusa amashanyarazi yibikoresho bya SiC ahubwo inazamura cyane imicungire yubushyuhe hamwe nubukanishi. Kubera iyo mpamvu, wafer ya SiCOI ikoreshwa cyane mubikoresho bya elegitoroniki, ibyuma bya radiyo (RF), sisitemu ya microelectromechanical sisitemu (MEMS), hamwe na electronics yubushyuhe bwo hejuru. Muri rusange, wafers ya SiCOI ihuza imiterere idasanzwe ya karubide ya silicon hamwe ninyungu zo kwigunga zamashanyarazi zo murwego rwa insulator, zitanga umusingi mwiza kubisekuru bizaza byibikoresho bikora neza cyane.

Gusaba wafer wa SiCOI

Ibikoresho bya elegitoroniki

Umuvuduko mwinshi hamwe nimbaraga nyinshi, MOSFETs, na diode

Wungukire kumurongo mugari wa SiC, imbaraga zo kumeneka cyane, hamwe nubushyuhe bwumuriro

Kugabanya gutakaza ingufu no kunoza imikorere muri sisitemu yo guhindura ingufu

Ibice bya Radio Frequency (RF)

Transistors-yumurongo mwinshi hamwe na amplifier

Ubushobozi buke bwa parasitike bitewe nubushakashatsi bwongera imikorere ya RF

Bikwiranye na 5G itumanaho na sisitemu ya radar

Sisitemu ya Microelectromechanical (MEMS)

Sensors hamwe na moteri ikora mubidukikije bikaze

Gukomera kwa mashini hamwe nubusembure bwimiti byongerera igihe ubuzima bwibikoresho

Harimo ibyuma byerekana ibyuma, umuvuduko wa moteri, na giroskopi

Ibikoresho bya elegitoroniki yo hejuru

Ibyuma bya elegitoronike kubinyabiziga, icyogajuru, hamwe ninganda zikoreshwa

Kora wizewe mubushyuhe bwo hejuru aho silicon yananiwe

Ibikoresho bya Photonic

Kwishyira hamwe hamwe nibikoresho bya optoelectronic kumashanyarazi

Gushoboza kuri chip Photonics hamwe no gucunga neza ubushyuhe

Ikibazo cya SiCOI wafer

Q :ni iki wafer wa SiCOI

A :Wafer ya SiCOI igereranya Silicon Carbide-kuri-Insulator wafer. Nubwoko bwa semiconductor substrate aho urwego ruto rwa karubide ya silicon (SiC) ihujwe kumurongo wikingira, mubisanzwe dioxyde de silicon (SiO₂) cyangwa rimwe na rimwe safiro. Iyi miterere isa mubitekerezo na waferi izwi cyane ya Silicon-kuri-Insulator (SOI) ariko ikoresha SiC aho gukoresha silicon.

Ishusho