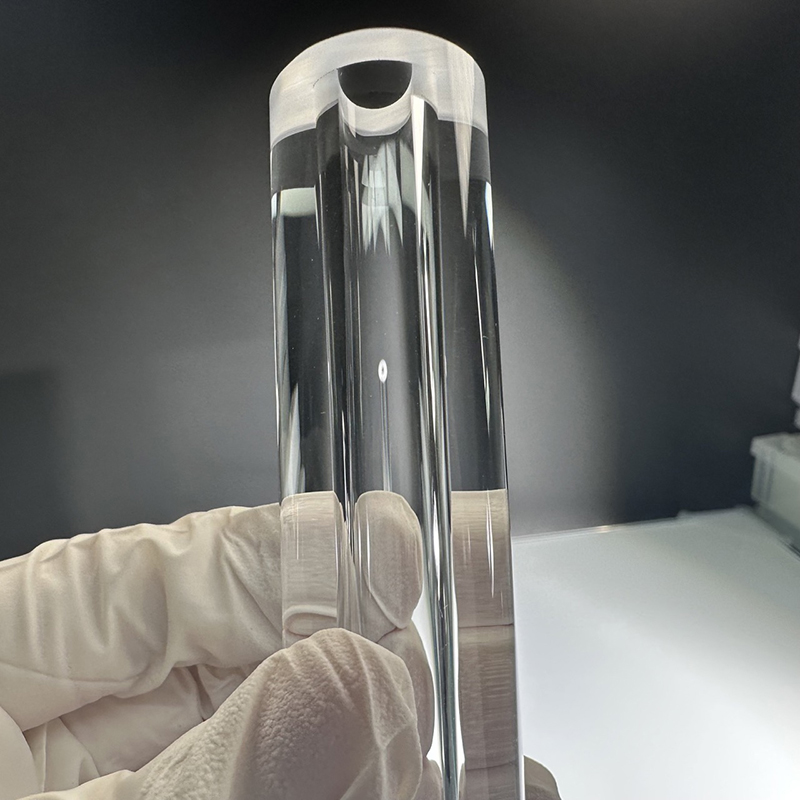

Semiconductor Laser Lift-Off Ibikoresho Guhindura Ingot Thinning

Igishushanyo kirambuye

Ibicuruzwa Kumenyekanisha Semiconductor Laser Lift-Off Ibikoresho

Ibikoresho bya Semiconductor Laser Lift-Off ni igisubizo cyihariye cyinganda zashizweho muburyo bwo gutomora neza no kudahuza kwinjizamo insimburangingo hifashishijwe tekinoroji yo kuzamura. Sisitemu yateye imbere igira uruhare runini mubikorwa bigezweho bya semiconductor, cyane cyane muguhimba ultra-thin wafers kumashanyarazi akomeye, ibikoresho bya LED, nibikoresho bya RF. Mugushoboza gutandukanya ibice byoroheje biva mubikoresho byinshi cyangwa abaterankunga, ibikoresho bya Semiconductor Laser Lift-Off ibikoresho bihindura ingonike yo gukuraho intoki, gusya, hamwe nintambwe zo gutera imiti.

Ubusanzwe kunanuka kwingirangingo ya semiconductor, nka nitride ya gallium (GaN), karbide ya silicon (SiC), na safiro, akenshi usanga bisaba akazi cyane, bigasesagura, kandi bikunda kwibasirwa na microcrake cyangwa kwangirika hejuru. Ibinyuranye, ibikoresho bya Semiconductor Laser Lift-Off ibikoresho bitanga ibintu bidasenya, bisobanutse neza bigabanya gutakaza ibintu hamwe nihungabana ryubutaka mugihe byongera umusaruro. Ifasha ibintu byinshi bya kristaline hamwe nibikoresho byuzuzanya kandi birashobora kwinjizwa muburyo budasubirwaho imbere cyangwa hagati yumurongo wa semiconductor.

Hamwe nuburebure bwa laser yumurongo, sisitemu yo guhuza imiterere, hamwe na vacuum ihuza na wafer chucks, ibi bikoresho birakwiriye cyane cyane gukata ingot, kurema lamella, hamwe na ultra-thin firime yoherejwe kubikoresho byububiko cyangwa kwimura ibice bya heteroepitaxial.

Parameter ya Semiconductor Laser Lift-Off Ibikoresho

| Uburebure | IR / SHG / THG / FHG |

|---|---|

| Ubugari bwa Pulse | Nanosekond, Picosekond, Femtosekond |

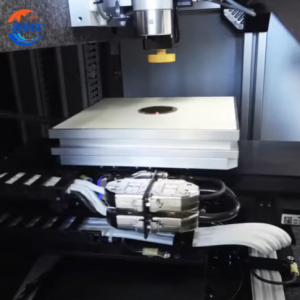

| Sisitemu nziza | Sisitemu ihamye cyangwa sisitemu ya Galvano-optique |

| Icyiciro cya XY | 500 mm × 500 mm |

| Urwego rwo gutunganya | Mm 160 |

| Umuvuduko wo kugenda | Max 1000 mm / amasegonda |

| Gusubiramo | ± 1 mm cyangwa munsi yayo |

| Umwanya wuzuye neza: | ± 5 mm cyangwa munsi yayo |

| Ingano ya Wafer | Santimetero 2-6 cyangwa kugenwa |

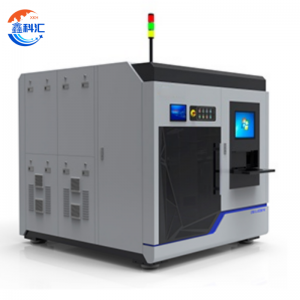

| Kugenzura | Windows 10,11 na PLC |

| Amashanyarazi | AC 200 V ± 20 V, Icyiciro kimwe, 50/60 kHz |

| Ibipimo byo hanze | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Ibiro | 1.000 kg |

Ihame ryakazi rya Semiconductor Laser Lift-Off ibikoresho

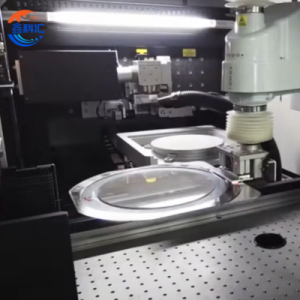

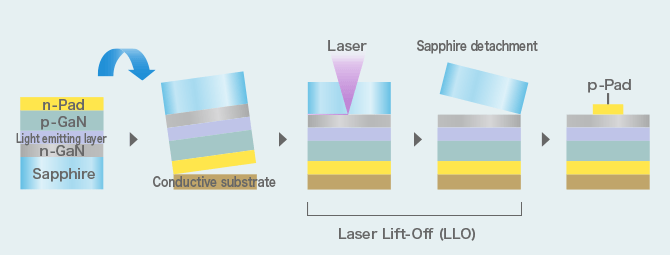

Uburyo bwibanze bwibikoresho bya Semiconductor Laser Lift-Off Ibikoresho bishingiye kubihitamo bifotora byangirika cyangwa kuvanaho intera hagati yumuterankunga ingot na epitaxial cyangwa intego. Laser ifite ingufu nyinshi UV (mubisanzwe KrF kuri 248 nm cyangwa ikomeye ya UV laseri hafi ya 355 nm) yibanda kumurongo wibikoresho utanga umucyo cyangwa igice kibonerana, aho ingufu zinjizwa muburyo bwimbitse.

Iyinjizwa ryingufu zaho zitera icyiciro cyumuvuduko mwinshi cyangwa icyiciro cyo kwagura ubushyuhe kuri interineti, gitangiza gusiba neza wafer yo hejuru cyangwa igikoresho cyibikoresho biva muri ingot. Inzira yatunganijwe neza muguhindura ibipimo nkubugari bwa pulse, laser fluence, scanning umuvuduko, hamwe na z-axis yibanze. Igisubizo ni ultra-thin igice-akenshi kiri hagati ya 10 na 50 µm - gitandukanijwe neza na ingot yababyeyi nta gukuramo imashini.

Ubu buryo bwo kuzamura lazeri yo kunanura ingot birinda gutakaza kerf no kwangirika kwubutaka bujyanye no kubona insinga ya diyama cyangwa gukubita imashini. Irinda kandi ubunyangamugayo bwa kirisiti kandi igabanya ibisabwa byo hasi ya polishinge, bigatuma Semiconductor Laser Lift-Off Ibikoresho bikoresha umukino uhindura umukino kubisekuruza bizaza.

Porogaramu ya Semiconductor Laser Lift-Off Ibikoresho

Semiconductor Laser Lift-Off Ibikoresho isanga bishoboka cyane mugutobora ingot kurwego rwibikoresho bigezweho hamwe nubwoko bwibikoresho, harimo:

-

GaN na GaAs Ingot Kunanuka kubikoresho byamashanyarazi

Gushoboza gukora wafer yoroheje kugirango ikorwe neza, tristoriste nkeya hamwe na diode.

-

SiC Substrate Gutangaza no Gutandukana kwa Lamella

Emerera wafer-igipimo cyo kuzamura kuva kuri SiC substrates yububiko bwibikoresho bihagaritse no gukoresha wafer.

-

LED Gukata

Yorohereza kuzamura ibice bya GaN biva mu bikoresho bya safiro byimbitse kugirango bitange ultra-thin LED substrates.

-

Ibikoresho bya RF na Microwave

Shyigikira ultra-thin high-electron-mobile-transistor (HEMT) ikenewe muri sisitemu ya 5G na radar.

-

Epitaxial Layeri Iyimura

Bitandukanya neza ibice bya epitaxial biva muri kristaline kugirango ikoreshwe cyangwa yinjizwe muri heterostructures.

-

Imirasire yizuba ya Solar selile na Photovoltaics

Byakoreshejwe gutandukanya ibice byoroheje byorohereza ingirabuzimafatizo zuba zoroshye.

Muri buri domeni, ibikoresho bya Semiconductor Laser Lift-Off ibikoresho bitanga igenzura ntagereranywa kuburinganire bwuburinganire, ubwiza bwubuso, hamwe nuburinganire bwurwego.

Ibyiza bya Laser-ishingiye kuri Ingot Thinning

-

Gutakaza Ibikoresho bya Zeru-Kerf

Ugereranije nuburyo gakondo bwo gukata wafer, inzira ya laser itanga ibisubizo hafi 100%.

-

Guhangayikishwa cyane no kurwana

Kudashyikirana-gukuramo gukuraho kunyeganyega kwa mashini, kugabanya umuheto wafer na microcrack.

-

Kubungabunga Ubuso Bwiza

Ntabwo nyuma yo kunanuka cyangwa gusya bisabwa mubihe byinshi, nkuko kuzamura laser bikomeza ubusugire bwo hejuru.

-

Byinshi byinjira kandi byikora byiteguye

Irashobora gutunganya amagana ya substrate kuri buri mwanya hamwe no gupakira byikora / gupakurura.

-

Bihuza nibikoresho byinshi

Bihujwe na GaN, SiC, safiro, GaAs, hamwe nibikoresho III-V bigenda bigaragara.

-

Ibidukikije bitekanye

Kugabanya ikoreshwa ryimiti hamwe nubumara bukaze busanzwe muburyo bworoshye.

-

Koresha Substrate

Abaterankunga baterankunga barashobora gutunganywa kugirango bazamure ibintu byinshi, bikagabanya cyane ibiciro.

Ibibazo Bikunze Kubazwa (FAQ) bya Semiconductor Laser Lift-Off ibikoresho

-

Q1: Ni ubuhe burebure bushobora kuba Semiconductor Laser Lift-Off Ibikoresho bishobora kugera kubice bya wafer?

A1:Ubucucike busanzwe buri hagati ya 10 µm kugeza 100 µm bitewe nibikoresho n'ibikoresho.Q2: Ibi bikoresho birashobora gukoreshwa muburyo bworoshye bukozwe mubikoresho bidasobanutse nka SiC?

A2:Yego. Muguhuza lazeri yumurambararo no gutezimbere ubuhanga bwa interineti (urugero, interlayers interlayers), ndetse nibikoresho bitagaragara birashobora gutunganywa.Q3: Nigute abaterankunga substrate bahujwe mbere yo kuzamura laser?

A3:Sisitemu ikoresha sub-micron iyerekwa rishingiye ku guhuza modul hamwe nibitekerezo bivuye ku bimenyetso bya fiducial hamwe nubuso bugaragaza.Q4: Ni ikihe gihe giteganijwe cyigihe cyo gukora laser imwe?

A4:Ukurikije ubunini bwa wafer nubunini, inzinguzingo zisanzwe zimara iminota 2 kugeza 10.Q5: Ese inzira isaba ibidukikije byisuku?

A5:Nubwo atari itegeko, guhuza ubwiherero birasabwa gukomeza kugira isuku yubutaka hamwe numusaruro wibikoresho mugihe cyibikorwa byuzuye.

Ibyerekeye Twebwe

XKH kabuhariwe mu iterambere ry’ikoranabuhanga rikomeye, gukora, no kugurisha ibirahuri bidasanzwe bya optique hamwe nibikoresho bishya bya kristu. Ibicuruzwa byacu bitanga ibikoresho bya elegitoroniki, ibikoresho bya elegitoroniki, n'abasirikare. Dutanga ibice bya optique ya optique, igifuniko cya terefone igendanwa, Ceramics, LT, Silicon Carbide SIC, Quartz, hamwe na semiconductor kristal wafers. Hamwe n'ubuhanga buhanga hamwe nibikoresho bigezweho, turi indashyikirwa mugutunganya ibicuruzwa bitari bisanzwe, tugamije kuba ibikoresho bya optoelectronic ibikoresho byubuhanga buhanitse.