SiC Ingot Gukura Itanura Kinini-Diameter SiC Crystal TSSG / LPE Uburyo

Ihame ry'akazi

Ihame shingiro ryamazi yo mu bwoko bwa silicon karbide ingot ikura harimo gushonga ibikoresho fatizo bya SiC bifite isuku ryinshi mubyuma byashongeshejwe (urugero, Si, Cr) kuri 1800-2100 ° C kugirango bibe ibisubizo byuzuye, hanyuma bikurikirwa no gukura kwerekanwa kwerekanwa rya kristu imwe ya kirisiti kuri kristu yimbuto binyuze mubushuhe bwuzuye bwikigereranyo no kurenza urugero. Iri koranabuhanga rirakwiriye cyane cyane kubyara ubuziranenge (> 99,9995%) 4H / 6H-SiC kristu imwe ifite ubucucike buke (<100 / cm²), byujuje ibyangombwa bisabwa kugirango ibikoresho bya elegitoroniki n’ibikoresho bya RF. Sisitemu yo gukura yibice byamazi ituma igenzura neza ubwoko bwa kristu itwara ibintu (ubwoko bwa N / P) hamwe nuburwanya binyuze muburyo bwiza bwo gukemura no gukura.

Ibigize

1.

2. Sisitemu yo gushyushya ibice byinshi: Gushyushya / gushyushya ubushyuhe hamwe no kugenzura ubushyuhe bwa dogere 0.5 ° C (intera ya 1800-2100 ° C).

3. Sisitemu Yimikorere Yuzuye: Kabiri ifunze-kugenzura kugenzura imbuto (0-50rpm) no guterura (0.1-10mm / h).

4. Sisitemu yo kugenzura ikirere: Kurinda cyane argon / azote, kurinda imbaraga zakazi (0.1-1atm).

5.

6. Sisitemu nziza yo gukonjesha: Igishushanyo mbonera cyo gukonjesha amazi cyerekana imikorere yigihe kirekire.

TSSG na LPE Kugereranya

| Ibiranga | Uburyo bwa TSSG | Uburyo bwa LPE |

| Gukura Ubushyuhe | 2000-2100 ° C. | 1500-1800 ° C. |

| Igipimo cyo gukura | 0.2-1mm / h | 5-50μm / h |

| Ingano ya Crystal | Ingano ya 4-8 | 50-500μm epi-ibice |

| Porogaramu nyamukuru | Kwitegura | Igikoresho cyamashanyarazi epi-layers |

| Ubucucike bwuzuye | <500 / cm² | <100 / cm² |

| Polytypes ikwiye | 4H / 6H-SiC | 4H / 3C-SiC |

Ibyingenzi

1. Imbaraga za elegitoroniki: 6-cm 4H-SiC substrate ya 1200V + MOSFETs / diode.

2. 5G Ibikoresho bya RF: Semi-insulasiyo ya SiC ya sitasiyo fatizo PAs.

3. Porogaramu ya EV: Ultra-yuzuye (> 200μm) epi-layer ya moderi-yimodoka.

4. Inverteri ya PV: Substrates nkeya zifite ubushobozi bwo guhindura> 99%.

Inyungu Zibanze

1. Ubukuru bw'ikoranabuhanga

1.1 Igishushanyo mbonera cyuburyo bwinshi

Sisitemu yo gukura ya SiC ingot yo gukura muburyo bushya ihuza TSSG na LPE tekinoroji yo gukura. Sisitemu ya TSSG ikoresha imbuto yo hejuru yimbuto ikura hamwe no kugenzura neza gushonga hamwe no kugenzura ubushyuhe bwikigereranyo (ΔT≤5 ℃ / cm), bigatuma imikurire ihamye yikura rya santimetero 4-8 za santimetero nini ya SiC hamwe numusaruro umwe wa 15-20 kg kuri 6H / 4H-SiC. Sisitemu ya LPE ikoresha uburyo bwiza bwo gukuramo ibishishwa (sisitemu ya Si-Cr alloy) hamwe no kugenzura supersaturation (± 1%) kugirango ikure neza cyane epitaxial yimbitse ifite ubwinshi bwinenge <100 / cm² kubushyuhe buke (1500-1800 ℃).

1.2 Sisitemu yo kugenzura ubwenge

Bifite ibikoresho byo mu gisekuru cya 4 bigenzura ubwenge bikura:

• Gukurikirana ibintu byinshi (400-2500nm yumurambararo)

• Lazeri ishingiye ku gushonga urwego (± 0.01mm neza)

• CCD ishingiye kuri diameter ifunze-kugenzura (<± 1mm ihindagurika)

• Gukoresha imbaraga za AI zikoreshwa neza (kuzigama ingufu 15%)

2. Gutunganya Inyungu Zimikorere

2.1 Uburyo bwa TSSG Uburyo bukomeye

• Ubushobozi bunini: Bishyigikira gukura kwa santimetero 8 na kristu hamwe na> 99.5%

• Ikirangantego cyo hejuru: Ubucucike bwa Dislocation <500 / cm², ubucucike bwa micropipe <5 / cm²

• Doping uburinganire: <8% n-ubwoko butandukanye bwo kurwanya (wafers-4)

• Gukura neza kwiterambere: Guhindura 0.3-1.2mm / h, 3-5 × byihuse kuruta uburyo bwa vapor-fase

2.2 Uburyo bwa LPE Uburyo bukomeye

• Epitaxy ya Ultra-nkeya: Ubucucike bwa leta <1 × 10¹¹cm⁻² · eV⁻¹

• Kugenzura neza umubyimba: 50-500μm epi-layer hamwe na <± 2% ubunini

• Ubushyuhe buke: 300-500 ℃ munsi ya CVD

• Gukura kwimiterere igoye: Gushyigikira pn ihuza, superlattices, nibindi.

3. Ibyiza byo gukora neza

3.1 Kugenzura ibiciro

• 85% gukoresha ibikoresho fatizo (ni 60% bisanzwe)

• 40% yo gukoresha ingufu nke (ugereranije na HVPE)

• 90% ibikoresho byigihe (igishushanyo mbonera kigabanya igihe cyo hasi)

3.2

• 6σ kugenzura inzira (CPK> 1.67)

• Kugaragaza inenge kumurongo (gukemura 0.1μm)

• Ibisobanuro byuzuye byuzuye (2000+ ibipimo nyabyo)

3.3 Ubunini

• Bihujwe na 4H / 6H / 3C polytypes

• Kuzamurwa muburyo bwa santimetero 12

• Shyigikira SiC / GaN hetero-kwishyira hamwe

4. Inyungu zo Gusaba Inganda

4.1 Ibikoresho by'ingufu

• Kurwanya imbaraga nke (0.015-0.025Ω · cm) kubikoresho 1200-3300V

• Semi-insulateri (> 10⁸Ω · cm) kubisabwa na RF

4.2 Ikoranabuhanga rishya

• Itumanaho rya Quantum: Ultra-low urusaku rwinshi (1 / f urusaku <-120dB)

• Ibidukikije bikabije: kristu irwanya imirasire (<5% kwangirika nyuma ya 1 × 10¹⁶n / cm² irrasiyo)

Serivisi za XKH

1. Ibikoresho byabigenewe: Iboneza rya TSSG / LPE.

2. Amahugurwa yuburyo: Gahunda zamahugurwa ya tekiniki.

3. Nyuma yo kugurisha Inkunga: 24/7 igisubizo cya tekiniki no kubungabunga.

4. Ibisubizo bya Turnkey: Serivise yuzuye kuva mugushiraho kugeza kwemeza.

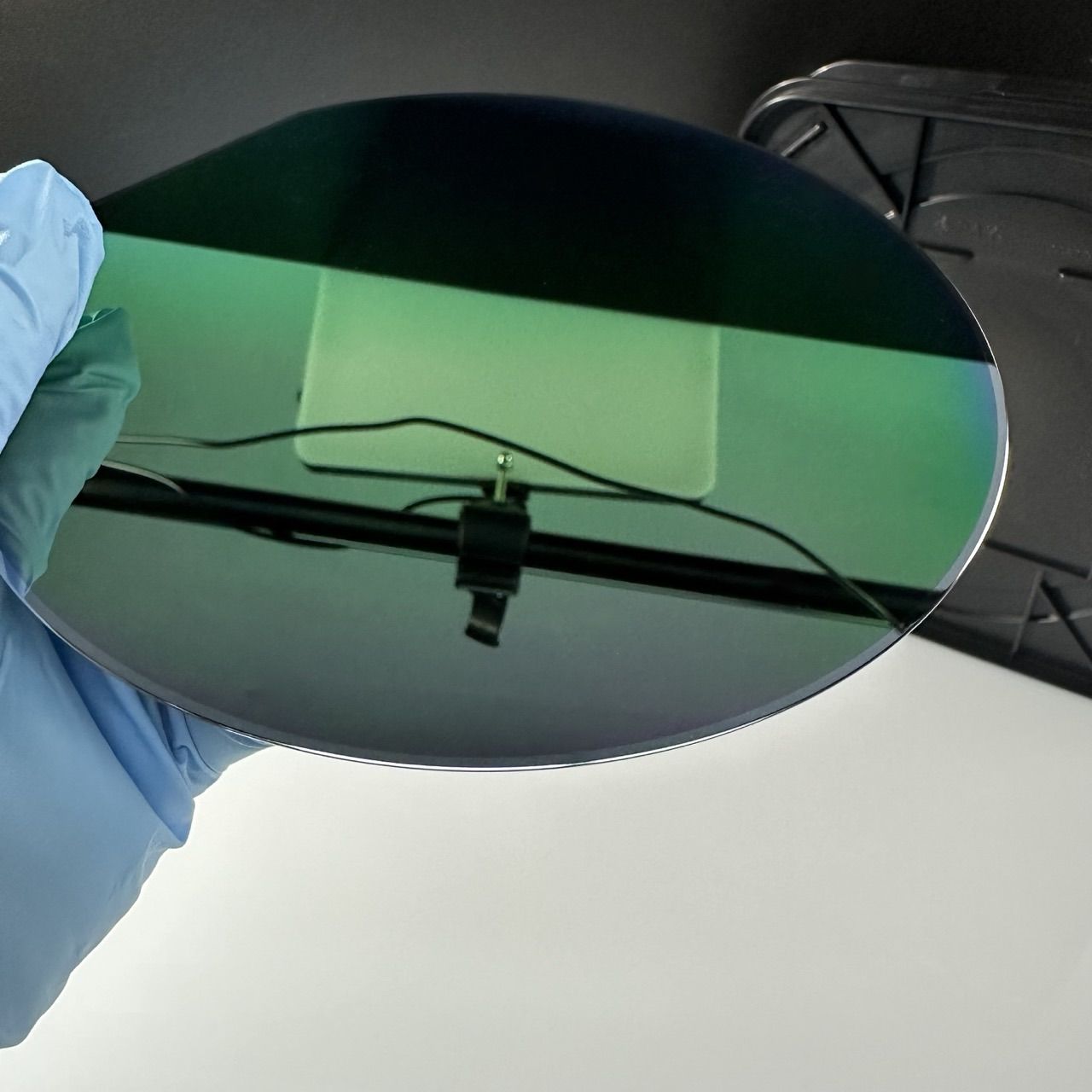

5. Gutanga ibikoresho: 2-12 cm SiC substrates / epi-wafers irahari.

Ibyiza byingenzi birimo:

• Kugera kuri santimetero 8 z'ubushobozi bwo gukura.

• Kurwanya uburinganire <0.5%.

• Ibikoresho byigihe> 95%.

24/7 inkunga ya tekiniki.