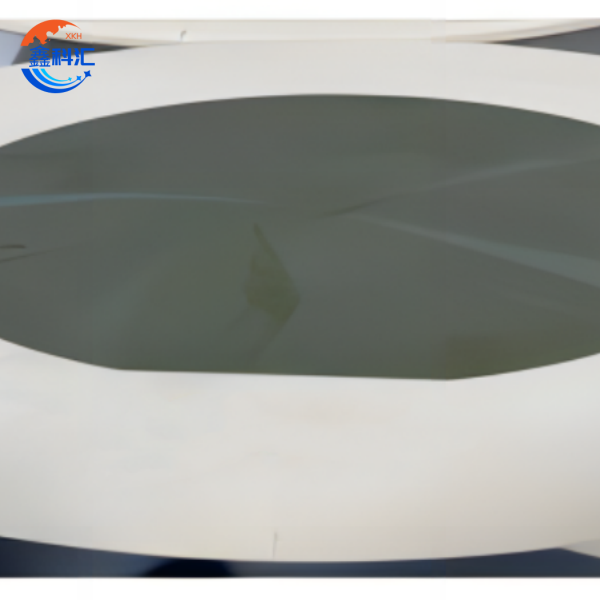

Ibikoresho bya Wafer Byoroheje kuri 4 Inch-12 Inch Sapphire / SiC / Si Wafers

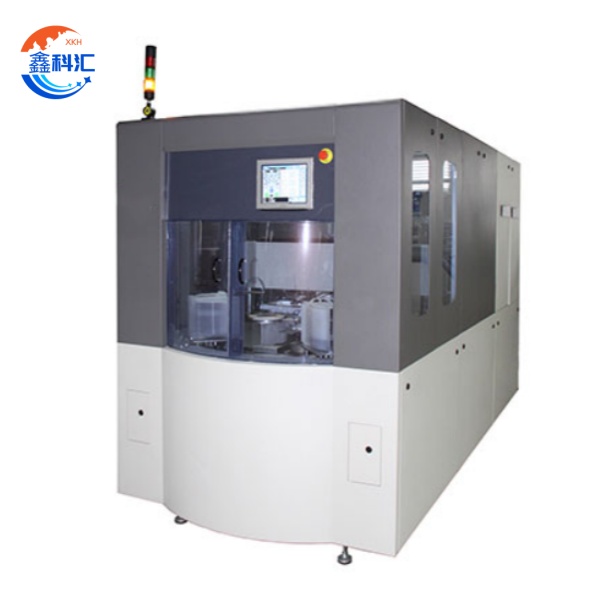

Ihame ry'akazi

Uburyo bwo kunanura wafer bukora mubice bitatu:

Gusya bikabije: Uruziga rwa diyama (grit ingana na 200-500 mm) ikuraho 50-150 mm yibikoresho kuri 3000-5000 rpm kugirango bigabanye vuba umubyimba.

Gusya neza: Uruziga rwiza (grit size 1-50 mm) rugabanya umubyimba kugeza kuri 20-50 mm kuri <1 μ m / s kugirango ugabanye kwangirika kwisi.

Kuringaniza (CMP): Imiti-mashini ikuraho ibyangiritse bisigaye, igera kuri Ra <0.1 nm.

Ibikoresho bihuye

Silicon (Si): Igipimo cya wafer ya CMOS, cyoroshye kugeza kuri 25 mm kuri stacking ya 3D.

Silicon Carbide (SiC): Irasaba ibiziga bya diyama kabuhariwe (80% bya diyama yibanze) kugirango ubushyuhe bwumuriro.

Safiro (Al₂O₃): Yoroheje kugeza kuri 50 mm kuri porogaramu ya UV LED.

Ibice bigize sisitemu

1. Sisitemu yo gusya

Imashini ebyiri-Axis: Ihuza gusya / gusya neza murwego rumwe, bigabanya igihe cyinzira 40%.

Indege ya Aerostatike: 0-6000 rpm yihuta hamwe na <0.5 μ m radial runout.

2. Sisitemu yo Gukoresha Wafer

Vacuum Chuck:> 50 N ifata imbaraga hamwe na ± 0.1 μ m ihagaze neza.

Ukuboko kwa robo: Gutwara wafer ya 4-12-kuri 100 mm / s.

3. Sisitemu yo kugenzura

Laser Interferometry: Kugenzura igihe nyacyo (gukemura 0.01 μm).

AI-Driven Feedforward: Ihanura kwambara ibiziga kandi ihindura ibipimo byikora.

4. Gukonjesha & Isuku

Ultrasonic Isuku: Ikuraho ibice> 0.5 μ m hamwe na 99.9%.

Amazi ya Deionized: Ubukonje bwa wafer kuri <5 ° C hejuru yibidukikije.

Inyungu Zibanze

1. Ultra-High Precision: TTV (Itandukaniro Ryuzuye Ryuzuye) <0.5 μ mm, WTW (Imbere-Wafer Ubunini Bwinshi) <1 μ m.

2. Kwishyira hamwe kwinshi: Gukomatanya gusya, CMP, na plasma byangiza mumashini imwe.

3. Guhuza Ibikoresho:

Silicon: Kugabanya umubyimba kuva kuri 775 mm kugeza kuri 25 mm.

SiC: Kugera <2 μm TTV kubisabwa na RF.

Wopers Wopers: Fosifore-yuzuye InP wafers hamwe na <5% yo kurwanya.

4. Automation Smart: Kwishyira hamwe kwa MES kugabanya amakosa yabantu 70%.

5. Ingufu zingufu: 30% ikoresha ingufu nkeya ukoresheje feri ishya.

Ibyingenzi

1. Gupakira neza

• 3D IC: Kugabanuka kwa Wafer bifasha gutondekanya vertical ya logic / memoire yibikoresho (urugero, ibice bya HBM), kugera kuri 10 × umurongo mwinshi kandi 50% byagabanije gukoresha amashanyarazi ugereranije na 2.5D ibisubizo. Ibikoresho bifasha guhuza imvange hamwe na TSV (Binyuze muri Silicon Via) guhuza, nibyingenzi kubitunganya AI / ML bisaba <10 μ m guhuza imiyoboro. Kurugero, waferi ya santimetero 12 zinanutse kugeza kuri 25 mm zemerera gutondekanya ibice 8+ mugihe ukomeza <1.5% yintambara, byingenzi kuri sisitemu yimodoka LiDAR.

• Gupakira abafana: Mugabanye uburebure bwa wafer kugera kuri 30 mkm, uburebure bwihuza bugabanywa na 50%, bikagabanya gutinda kw'ibimenyetso (<0.2 ps / mm) kandi bigafasha 0,4 mm za ultra-thin chiplets kuri SoCs zigendanwa. Inzira ikoresha imbaraga zo gusya algorithms kugirango wirinde urupapuro rwintambara (> 50 μm TTV igenzura), rwemeza kwizerwa mubikorwa byinshi bya RF.

2. Amashanyarazi

• Module ya IGBT: Kugabanuka kugeza kuri 50 mm bigabanya ubushyuhe bwumuriro kuri <0.5 ° C / W, bigatuma MOSFETS 1200V SiC ikora kuri 200 ° C. Ibikoresho byacu bikoresha ibyiciro byinshi byo gusya (coarse: 46 μm grit → byiza: 4 μ m grit) kugirango bikureho ibyangiritse munsi yubutaka, bigera ku> 10,000 byikurikiranya ryumuriro wamagare. Ibi nibyingenzi kuri inverteri ya EV, aho waferi ya 10 mm-yuburebure bwa SiC itezimbere umuvuduko wo guhinduranya 30%.

• Ibikoresho by'ingufu za GaN-kuri-SiC: Kugabanuka kwa Wafer kugera kuri 80 mμ byongera umuvuduko wa electron (μ> 2000 cm² / V · s) kuri 650V GaN HEMTs, bikagabanya igihombo cyo gutwara 18%. Inzira ikoresha lazeri ifashwa na laser kugirango irinde gucika mugihe cyo kunanuka, kugera kuri <5 μm edge chipping for RF power amplifier.

3. Amashanyarazi

• GaN-kuri-SiC LEDs: 50 mm ya safiro substrate itezimbere uburyo bwo gukuramo urumuri (LEE) kugeza kuri 85% (v. Ibikoresho byacu bya ultra-low TTV igenzura (<0.3 μ m) ituma imyuka imwe ya LED isohoka muri waferi ya santimetero 12, ingenzi kuri ecran ya Micro-LED isaba <100nm uburebure bwumurongo.

• Silicon Photonics: 25 mm-yuburebure bwa silicon wafers ituma igabanuka rya 3 dB / cm munsi yo gukwirakwizwa mumashanyarazi, byingenzi kuri 1.6 Tbps ya optique ya optique. Inzira ihuza CMP yoroshye kugirango igabanye ubuso bwa Ra <0.1 nm, byongera imikorere ya 40%.

4. Sensors za MEMS

• Umuvuduko wihuse: 25 mμm silicon wafers igera kuri SNR> 85 dB (umurongo wa 75 dB kuri 50 μ m wafers) mukongera ibyiyumvo byimuka byimuka. Sisitemu yacu yo gusya kabiri-isubiza ibyangiritse, ikemeza ko <0.5% ibyiyumvo bigenda hejuru ya -40 ° C kugeza kuri 125 ° C. Porogaramu zirimo impanuka yimodoka hamwe na AR / VR ikurikirana.

• Ibyumviro byumuvuduko: Kugabanuka kugeza kuri 40 mm bituma ibipimo 0-300 bipima ibipimo hamwe na <0.1% FS hystereze. Ukoresheje guhuza by'agateganyo (abatwara ibirahuri), inzira irinda kuvunika wafer mugihe cyo gutera inyuma, kugera kuri <1 μm kwihanganira gukabya kwihanganira inganda za IoT.

• Gukoresha tekinike: Ibikoresho byacu byo kunanura wafer bihuza gusya, CMP, hamwe na plasma kugirango bikemure ibibazo bitandukanye (Si, SiC, Sapphire). Kurugero, GaN-kuri-SiC isaba gusya imvange (ibiziga bya diyama + plasma) kugirango iringanize ubukana no kwaguka kwinshi, mugihe sensor ya MEMS isaba munsi ya 5 nm hejuru yubutaka hakoreshejwe CMP.

• Ingaruka zinganda: Mugushoboza waferi yoroheje, ikora neza cyane, ubu buryo bwikoranabuhanga butera udushya muri chip ya AI, modul ya 5G mmWave, hamwe na elegitoroniki yoroheje, hamwe na TTV yihanganira <0.1 μm kubishobora kwerekanwa na <0.5 μm kumashanyarazi ya LiDAR.

Serivisi za XKH

1. Ibisubizo byihariye

Ibipimo binini: Ibishushanyo bya 4-12-byumba byashushanyije hamwe no gupakira byikora / gupakurura.

Inkunga ya Doping: Ibisobanuro byihariye bya Er / Yb-byanditseho kristu na InP / GaAs wafers.

2. Inkunga iherezo-iherezo

Gutezimbere Inzira: Ikigeragezo cyubuntu gikora neza.

Amahugurwa ku Isi: Amahugurwa ya tekiniki buri mwaka kubijyanye no kubungabunga no gukemura ibibazo.

3. Gutunganya ibintu byinshi

SiC: Wafer kunanuka kugeza kuri 100 mm hamwe na Ra <0.1 nm.

Safiro: uburebure bwa 50μm kuri Windows ya laser laser (transmitance> 92% @ 200 nm).

4. Serivisi zongerewe agaciro

Isoko rikoreshwa: Ibiziga bya diyama (2000+ wafers / ubuzima) hamwe na CMP.

Umwanzuro

Ibikoresho bya wafer binaniza bitanga inganda ziyobora neza, ibintu byinshi bihindagurika, hamwe nubwikorezi bwubwenge, bigatuma biba ngombwa muguhuza 3D hamwe na electronics power. Serivisi zuzuye za XKH - kuva kubitondekanya kugeza nyuma yo gutunganywa - kwemeza abakiriya kugera kubikorwa byigiciro no kuba indashyikirwa mubikorwa bya semiconductor.