4H-N HPSI SiC wafer 6H-N 6H-P 3C-N SiC Epitaxial wafer ya MOS cyangwa SBD

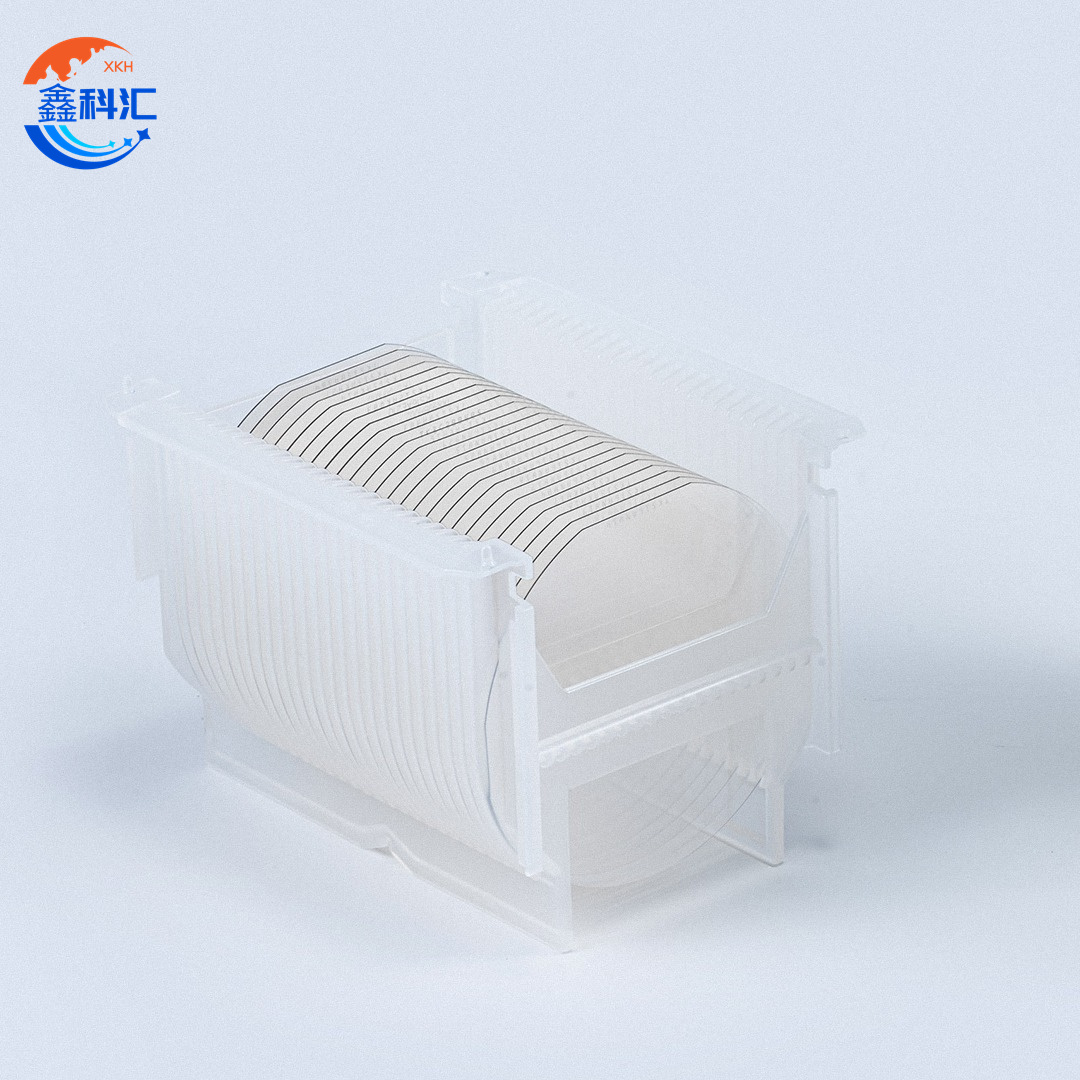

SiC Substrate SiC Epi-wafer Incamake

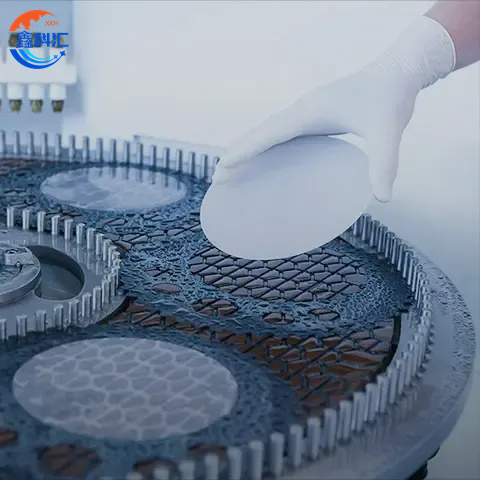

Dutanga portfolio yuzuye ya sisitemu yo mu rwego rwohejuru ya SiC hamwe na sic wafers muri polytypes nyinshi hamwe na doping imyirondoro - harimo 4H-N (imiyoboro yo mu bwoko bwa n), 4H-P (imiyoboro yo mu bwoko bwa p), 4H-HPSI (igice kinini cy-isuku), na 6H-P (p-p) Kurenga substrate yambaye ubusa, serivisi ziyongera kuri epi wafer serivisi zitanga serivise zitanga epitaxial (epi) wafers hamwe nubugari bugenzurwa cyane (1-20 µm), kwibanda kuri doping, hamwe nubucucike.

Buri sic wafer na epi wafer ikorerwa igenzura rikomeye kumurongo (ubucucike bwa micropipe <0.1 cm⁻², ubukana bwa Ra <0.2 nm) hamwe no kuranga amashanyarazi yuzuye (CV, ikarita yo kurwanya) kugirango habeho uburinganire budasanzwe kandi bukora. Byaba bikoreshwa mumashanyarazi ya elegitoroniki, ibyuma byongera ingufu za RF, cyangwa ibikoresho bya optoelectronic (LEDs, Photodetector), imirongo ya SiC substrate na epi wafer ibicuruzwa bitanga ubwizerwe, ituze ryumuriro, nimbaraga zo gusenyuka bisabwa nibisabwa muri iki gihe.

SiC Substrate ya 4H-N ubwoko bwimiterere nibisabwa

-

4H-N SiC substrate Polytype (Hexagonal) Imiterere

Umuyoboro mugari wa ~ 3.26 eV utuma amashanyarazi akora neza hamwe nubushyuhe bwumuriro mugihe cy'ubushyuhe bwinshi hamwe n’umuriro mwinshi w'amashanyarazi.

-

SiC substrateN-Ubwoko bwa Doping

Kugenzura neza azote doping itanga ubwikorezi bwabatwara kuva kuri 1 × 10¹⁶ kugeza kuri 1 × 10¹⁹ cm⁻³ hamwe nubushyuhe bwo mucyumba ubushyuhe bwa elegitoronike bugera kuri ~ 900 cm² / V · s, bikagabanya igihombo cyo gutwara.

-

SiC substrateKwiyongera kwinshi & Uniformity

Kuboneka birwanya 0,01-10 Ω · cm hamwe nuburebure bwa wafer bwa 350-650 µm hamwe no kwihanganira ± 5% haba muri doping no mubyimbye - nibyiza kubihimbano byimbaraga nyinshi.

-

SiC substrateUbucucike bukabije

Ubucucike bwa Micropipe <0.1 cm⁻² hamwe nubucucike bwindege ya basal-500 cm⁻², gutanga> 99% umusaruro wibikoresho hamwe nuburinganire bwikirenga.

- SiC substrateImyitwarire idasanzwe yubushyuhe

Amashanyarazi agera kuri ~ 370 W / m · K yorohereza gukuraho ubushyuhe neza, bizamura ibikoresho byizewe nubucucike bwimbaraga.

-

SiC substrateIntego Porogaramu

SiC MOSFETs, diode ya Schottky, modules yamashanyarazi nibikoresho bya RF kubinyabiziga bitwara ibinyabiziga byamashanyarazi, imirasire yizuba, moteri yinganda, sisitemu yo gukurura, nandi masoko asaba ingufu-electronics.

6inch 4H-N ubwoko bwa SiC wafer ibisobanuro | ||

| Umutungo | Impamyabumenyi ya Zeru MPD (Z Grade) | Icyiciro cya Dummy (D Grade) |

| Icyiciro | Impamyabumenyi ya Zeru MPD (Z Grade) | Icyiciro cya Dummy (D Grade) |

| Diameter | 149.5 mm - mm 150.0 | 149.5 mm - mm 150.0 |

| Ubwoko bwa poly | 4H | 4H |

| Umubyimba | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Icyerekezo cya Wafer | Hanze ya axis: 4.0 ° yerekeza kuri <1120> ± 0.5 ° | Hanze ya axis: 4.0 ° yerekeza kuri <1120> ± 0.5 ° |

| Ubucucike bwa Micropipe | ≤ 0.2 cm² | ≤ 15 cm² |

| Kurwanya | 0.015 - 0.024 Ω · cm | 0.015 - 0.028 Ω · cm |

| Icyerekezo Cyibanze | [10-10] ± 50 ° | [10-10] ± 50 ° |

| Uburebure bwibanze | 475 mm ± 2,2 mm | 475 mm ± 2,2 mm |

| Guhezwa | Mm 3 | Mm 3 |

| LTV / TIV / Umuheto / Intambara | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Ubugome | Igipolonye Ra ≤ 1 nm | Igipolonye Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Impande Zimenetse Kumucyo mwinshi | Uburebure bwa mm 20 mm z'uburebure mm 2 mm | Uburebure bwa mm 20 mm z'uburebure mm 2 mm |

| Isahani ya Hex Kumucyo mwinshi | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 0.1% |

| Uturere twa Polytype Kumucyo mwinshi | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 3% |

| Amashusho ya Carbone | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 5% |

| Igishushanyo cya Silicon Igishushanyo Cyinshi Cyumucyo | Uburebure bwuzuye ≤ 1 wafer diameter | |

| Imipira yimpande yumucyo mwinshi | Nta numwe wemerewe ≥ 0.2 mm z'ubugari n'uburebure | 7 byemewe, mm 1 mm imwe imwe |

| Gutandukanya imirongo | <500 cm³ | <500 cm³ |

| Ubuso bwa Silicon Yanduye Kumucyo mwinshi | ||

| Gupakira | Cassette ya Multi-wafer Cyangwa Igikoresho kimwe cya Wafer | Cassette ya Multi-wafer Cyangwa Igikoresho kimwe cya Wafer |

8inch 4H-N ubwoko bwa SiC wafer ibisobanuro | ||

| Umutungo | Impamyabumenyi ya Zeru MPD (Z Grade) | Icyiciro cya Dummy (D Grade) |

| Icyiciro | Impamyabumenyi ya Zeru MPD (Z Grade) | Icyiciro cya Dummy (D Grade) |

| Diameter | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Ubwoko bwa poly | 4H | 4H |

| Umubyimba | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Icyerekezo cya Wafer | 4.0 ° yerekeza kuri <110> ± 0.5 ° | 4.0 ° yerekeza kuri <110> ± 0.5 ° |

| Ubucucike bwa Micropipe | ≤ 0.2 cm² | Cm 5 cm² |

| Kurwanya | 0.015 - 0.025 Ω · cm | 0.015 - 0.028 Ω · cm |

| Icyerekezo Cyiza | ||

| Guhezwa | Mm 3 | Mm 3 |

| LTV / TIV / Umuheto / Intambara | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Ubugome | Igipolonye Ra ≤ 1 nm | Igipolonye Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Impande Zimenetse Kumucyo mwinshi | Uburebure bwa mm 20 mm z'uburebure mm 2 mm | Uburebure bwa mm 20 mm z'uburebure mm 2 mm |

| Isahani ya Hex Kumucyo mwinshi | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 0.1% |

| Uturere twa Polytype Kumucyo mwinshi | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 3% |

| Amashusho ya Carbone | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 5% |

| Igishushanyo cya Silicon Igishushanyo Cyinshi Cyumucyo | Uburebure bwuzuye ≤ 1 wafer diameter | |

| Imipira yimpande yumucyo mwinshi | Nta numwe wemerewe ≥ 0.2 mm z'ubugari n'uburebure | 7 byemewe, mm 1 mm imwe imwe |

| Gutandukanya imirongo | <500 cm³ | <500 cm³ |

| Ubuso bwa Silicon Yanduye Kumucyo mwinshi | ||

| Gupakira | Cassette ya Multi-wafer Cyangwa Igikoresho kimwe cya Wafer | Cassette ya Multi-wafer Cyangwa Igikoresho kimwe cya Wafer |

4H-SiC ni ibikoresho bikora cyane bikoreshwa mubikoresho bya elegitoroniki, ibikoresho bya RF, hamwe nubushyuhe bwo hejuru. "4H" bivuga imiterere ya kristu, ifite impande esheshatu, naho "N" yerekana ubwoko bwa doping bukoreshwa mugutezimbere imikorere yibikoresho.

Uwiteka4H-SiCubwoko bukoreshwa cyane kuri:

Amashanyarazi:Ikoreshwa mubikoresho nka diode, MOSFETs, na IGBTs kumashanyarazi yimodoka, imashini zinganda, hamwe na sisitemu yingufu zishobora kuvugururwa.

Ikoranabuhanga rya 5G:Hamwe na 5G isaba ibintu byinshi-byihuta kandi bikora neza, ubushobozi bwa SiC bwo gukoresha amashanyarazi menshi no gukora mubushyuhe bwinshi bituma biba byiza kubikoresho byongera ingufu za sitasiyo n’ibikoresho bya RF.

Imirasire y'izuba:Ibikoresho byiza bya SiC bifata neza nibyiza kuri fotokoltaque (izuba ryizuba) inverter na reveri.

Ibinyabiziga by'amashanyarazi (EV):SiC ikoreshwa cyane muri EV powertrain kugirango ihindure ingufu neza, kubyara ubushyuhe buke, nubucucike bukabije.

SiC Substrate 4H Semi-Gukingira ubwoko bwimiterere nibisabwa

Ibyiza:

-

Micropipe idafite ubuhanga bwo kugenzura ubucucike: Iremeza ko hatabaho micropipes, kuzamura ubwiza bwa substrate.

-

Uburyo bwo kugenzura Monocrystalline: Yemeza imiterere imwe ya kristu yo kuzamura ibikoresho.

-

Ubuhanga bwo kugenzura: Kugabanya ahari umwanda cyangwa ibirimo, kwemeza substrate nziza.

-

Ubuhanga bwo kurwanya: Emerera kugenzura neza kurwanya amashanyarazi, nibyingenzi mumikorere yibikoresho.

-

Ubuhanga bwo kugenzura no kugenzura: Igenga kandi igabanya kwinjiza umwanda kugirango ubungabunge ubusugire.

-

Substrate intambwe y'ubugari bwo kugenzura: Itanga igenzura ryukuri kubugari bwintambwe, iremeza guhuzagurika kuri substrate

6Muri 4H-igice cya SiC substrate ibisobanuro | ||

| Umutungo | Impamyabumenyi ya Zeru MPD (Z Grade) | Icyiciro cya Dummy (D Grade) |

| Diameter (mm) | Mm 145 - mm 150 | Mm 145 - mm 150 |

| Ubwoko bwa poly | 4H | 4H |

| Umubyimba (um) | 500 ± 15 | 500 ± 25 |

| Icyerekezo cya Wafer | Ku murongo: ± 0.0001 ° | Ku murongo: ± 0.05 ° |

| Ubucucike bwa Micropipe | Cm 15 cm-2 | Cm 15 cm-2 |

| Kurwanya (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Icyerekezo Cyibanze | (0-10) ° ± 5.0 ° | (10-10) ° ± 5.0 ° |

| Uburebure bwibanze | Ikimenyetso | Ikimenyetso |

| Guhezwa ku mpande (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Igikombe / Intambara | ≤ 3 µm | ≤ 3 µm |

| Ubugome | Igipolonye Ra ≤ 1.5 µm | Igipolonye Ra ≤ 1.5 µm |

| Imipira yimpande yumucyo mwinshi | ≤ 20 µm | ≤ 60 µm |

| Shyushya Amasahani Kumucyo mwinshi | Igiteranyo ≤ 0.05% | Gukusanya ≤ 3% |

| Uturere twa Polytype Kumucyo mwinshi | Amashusho agaragara ya Carbone ≤ 0.05% | Gukusanya ≤ 3% |

| Igishushanyo cya Silicon Igishushanyo Cyinshi Cyumucyo | ≤ 0,05% | Umubare ≤ 4% |

| Imipira yimpande yumucyo mwinshi (Ingano) | Ntibyemewe> 02 mm Ubugari n'Uburebure | Ntibyemewe> 02 mm Ubugari n'Uburebure |

| Imfashanyo Yagutse | ≤ 500 µm | ≤ 500 µm |

| Ubuso bwa Silicon Yanduye Kumucyo mwinshi | ≤ 1 x 10 ^ 5 | ≤ 1 x 10 ^ 5 |

| Gupakira | Multi-wafer Cassette cyangwa Igikoresho kimwe cya Wafer | Multi-wafer Cassette cyangwa Igikoresho kimwe cya Wafer |

4-Inch 4H-Semi Irondora SiC Substrate Ibisobanuro

| Parameter | Impamyabumenyi ya Zeru MPD (Z Grade) | Icyiciro cya Dummy (D Grade) |

|---|---|---|

| Ibintu bifatika | ||

| Diameter | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Ubwoko bwa poly | 4H | 4H |

| Umubyimba | 500 μ m ± 15 mm | 500 μm ± 25 mm |

| Icyerekezo cya Wafer | Ku murongo: <600h> 0.5 ° | Ku murongo: <000h> 0.5 ° |

| Ibyiza by'amashanyarazi | ||

| Ubucucike bwa Micropipe (MPD) | ≤1 cm⁻² | ≤15 cm⁻² |

| Kurwanya | ≥150 Ω · cm | ≥1.5 Ω · cm |

| Ubworoherane bwa Geometrike | ||

| Icyerekezo Cyibanze | (0x10) ± 5.0 ° | (0x10) ± 5.0 ° |

| Uburebure bwibanze | 52.5 mm ± 2,2 mm | 52.5 mm ± 2,2 mm |

| Uburebure bwa kabiri | 18.0 mm ± 2,2 mm | 18.0 mm ± 2,2 mm |

| Icyerekezo cya kabiri cya Flat | 90 ° CW kuva kuri Prime igororotse ± 5.0 ° (Si reba hejuru) | 90 ° CW kuva kuri Prime igororotse ± 5.0 ° (Si reba hejuru) |

| Guhezwa | Mm 3 | Mm 3 |

| LTV / TTV / Umuheto / Intambara | ≤2.5 μ m / ≤5 μ m / ≤15 μ m / ≤30 mm | ≤10 μ m / ≤15 μ m / ≤25 μ m / ≤40 mm |

| Ubwiza bw'ubuso | ||

| Ubuso Bwuzuye (Igipolonye Ra) | ≤1 nm | ≤1 nm |

| Ubuso Bwuzuye (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Ibice byo ku nkombe (Umucyo mwinshi) | Ntabwo byemewe | Uburebure bwa mm10 mm, igikoma kimwe mm2 mm |

| Inenge ya Hexagonal | ≤0.05% agace kegeranye | ≤0.1% agace kegeranye |

| Ibice birimo Polytype | Ntabwo byemewe | ≤1% agace kegeranye |

| Amashusho ya Carbone | ≤0.05% agace kegeranye | ≤1% agace kegeranye |

| Igishushanyo cya Silicon | Ntabwo byemewe | ≤1 wafer diameter cumulative uburebure |

| Imipira | Ntanumwe wemerewe (≥0.2 mm ubugari / ubujyakuzimu) | Chip5 chip (buri ≤1 mm) |

| Ubuso bwa Silicon | Ntabwo bisobanuwe neza | Ntabwo bisobanuwe neza |

| Gupakira | ||

| Gupakira | Cassette ya Multi-Wafer cyangwa ikintu kimwe cya wafer | Cassette ya Multi-wafer cyangwa |

Gusaba:

UwitekaSiC 4H Semi-Ihindura insimburangingozikoreshwa cyane cyane mububasha bukomeye kandi bwihuta cyane ibikoresho bya elegitoronike, cyane cyane muriUmwanya wa RF. Izi substrate ningirakamaro kubikorwa bitandukanye birimosisitemu y'itumanaho rya microwave, icyiciro cya radar, naamashanyarazi adafite amashanyarazi. Ubushyuhe bwumuriro mwinshi hamwe nibyiza byamashanyarazi bituma biba byiza basaba amashanyarazi muri sisitemu ya elegitoroniki na sisitemu yitumanaho.

SiC epi wafer 4H-N ubwoko bwimiterere nibisabwa

SiC 4H-N Ubwoko bwa Epi Wafer Ibyiza na Porogaramu

Ibyiza bya SiC 4H-N Ubwoko bwa Epi Wafer:

Ibigize ibikoresho:

SiC (Carbide ya Silicon): Azwiho gukomera gukomeye, gutwara ubushyuhe bwinshi, hamwe n’amashanyarazi meza cyane, SiC nibyiza kubikoresho bya elegitoroniki bikora cyane.

4H-SiC Polytype: 4H-SiC polytype izwiho gukora neza no gutuza mubikorwa bya elegitoroniki.

N-Ubwoko bwa Doping.

Ubushyuhe bwo hejuru cyane:

WaC ya SiC ifite ubushyuhe bwikirenga bwumuriro, mubisanzwe kuva120–200 W / m · K., kubemerera gucunga neza ubushyuhe mubikoresho bifite ingufu nyinshi nka transistors na diode.

Umuyoboro mugari:

Hamwe na bande ya3.26 eV, 4H-SiC irashobora gukora kuri voltage nyinshi, inshuro nyinshi, nubushyuhe ugereranije nibikoresho gakondo bishingiye kuri silikoni, bigatuma biba byiza kubikorwa byiza, bikora neza.

Ibyiza by'amashanyarazi:

SiC yo hejuru ya elegitoronike igenda neza kandi ikora nezaibikoresho bya elegitoroniki, gutanga umuvuduko wihuse hamwe nubushobozi bwo hejuru hamwe na voltage yo gukoresha, bikavamo sisitemu yo gucunga neza imikorere.

Kurwanya Imashini na Shimi:

SiC ni kimwe mu bikoresho bigoye, icya kabiri nyuma ya diyama, kandi irwanya cyane okiside na ruswa, bigatuma iramba ahantu habi.

Porogaramu ya SiC 4H-N Ubwoko bwa Epi Wafer:

Amashanyarazi:

Ubwoko bwa SiC 4H-N epi wafers ikoreshwa cyane muriimbaraga MOSFETS, IGBTs, nadiodeKuriguhindura imbaragamuri sisitemu nkaizuba, ibinyabiziga by'amashanyarazi, nasisitemu yo kubika ingufu, gutanga imikorere yongerewe imbaraga no gukora neza.

Ibinyabiziga by'amashanyarazi (EV):

In amashanyarazi yimodoka, abagenzuzi ba moteri, nasitasiyo, Wafers ya SiC ifasha kugera kubikorwa byiza bya bateri, kwishyurwa byihuse, no kunoza imikorere muri rusange bitewe nubushobozi bwabo bwo gukoresha ingufu nubushyuhe bwinshi.

Sisitemu y'ingufu zishobora kuvugururwa:

Imirasire y'izuba: Wafers ya SiC ikoreshwa murisisitemu y'izubayo guhindura ingufu za DC ziva mumirasire y'izuba kuri AC, kongera imikorere muri rusange imikorere n'imikorere.

Umuyaga: Ikoranabuhanga rya SiC rikoreshwa murisisitemu yo kugenzura umuyaga, gutezimbere amashanyarazi no gukora neza.

Ikirere n'Ingabo:

SiC wafers nibyiza gukoreshwa muriicyogajurunagusaba gisirikare, harimosisitemu ya radarnaibikoresho bya elegitoroniki, aho imirasire irwanya imbaraga hamwe nubushyuhe bwumuriro ni ngombwa.

Ubushyuhe Bwinshi na-Byihuse-Porogaramu:

SiC wafers nziza cyaneibikoresho bya elegitoroniki byo hejuru, Byakoreshejwe murimoteri yindege, icyogajuru, nauburyo bwo gushyushya inganda, nkuko bakomeza imikorere mubihe byubushyuhe bukabije. Byongeye kandi, umurongo mugari wemerera gukoreshaPorogaramu nyinshinkaIbikoresho bya RFnaitumanaho rya microwave.

| 6-santimetero N-ubwoko bwa epit axial ibisobanuro | |||

| Parameter | igice | Z-MOS | |

| Andika | Conditivity / Dopant | - | N-Ubwoko / Azote |

| Buffer | Ubunini bwa Buffer | um | 1 |

| Buffer Urwego rwo Kworoherana | % | ± 20% | |

| Ihuriro rya Buffer | cm-3 | 1.00E + 18 | |

| Buffer Layeri Yibanze Kwihanganirana | % | ± 20% | |

| Igice cya 1 Epi | Epi Umubyimba | um | 11.5 |

| Epi Umubyimba Uburinganire | % | ± 4% | |

| Epi Imirongo Yoroherana ((Ubwoko- Max , Min) / Ubwoko) | % | ± 5% | |

| Epi Yibanze | cm-3 | 1E 15 ~ 1E 18 | |

| Epi Igice cyo Kworoherana | % | 6% | |

| Epi Igice cyo Kwishyira hamwe (σ / bivuze) | % | ≤5% | |

| Epi Igice cyo Kwishyira hamwe <(max-min) / (max + min> | % | ≤ 10% | |

| Epitaixal Wafer Shape | Umuheto | um | ≤ ± 20 |

| INTAMBARA | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Ibiranga rusange | Uburebure | mm | ≤30mm |

| Imipira | - | NTAWE | |

| Inenge | ≥97% Yapimwe na 2 * 2 , Inenge z'abicanyi zirimo: Inenge zirimo Micropipe / Ibyobo binini, Karoti, inyabutatu | ||

| Kwanduza ibyuma | atom / cm² | d f f ll i ≤5E10 atom / cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Amapaki | Gupakira ibisobanuro | pcs / agasanduku | cassette nyinshi-wafer cyangwa ikintu kimwe cya wafer |

| 8-santimetero N-ubwoko bwa epitaxial | |||

| Parameter | igice | Z-MOS | |

| Andika | Conditivity / Dopant | - | N-Ubwoko / Azote |

| Buffer | Ubunini bwa Buffer | um | 1 |

| Buffer Urwego rwo Kworoherana | % | ± 20% | |

| Ihuriro rya Buffer | cm-3 | 1.00E + 18 | |

| Buffer Layeri Yibanze Kwihanganirana | % | ± 20% | |

| Igice cya 1 Epi | Ikigereranyo cya Epi | um | 8 ~ 12 |

| Epi Ibice Byinshi Uburinganire (σ / bivuze) | % | ≤2.0 | |

| Epi Imirongo Yoroheye ((Ubwoko -Max , Min) / Ubwoko) | % | ± 6 | |

| Epi Layers Net Impuzandengo ya Doping | cm-3 | 8E + 15 ~ 2E + 16 | |

| Epi Imirongo Net Doping Uniformity (σ / bivuze) | % | ≤5 | |

| Epi Imirongo Net DopingTolerance ((Ubwoko -Max , | % | ± 10.0 | |

| Epitaixal Wafer Shape | Mi) / S) Intambara | um | ≤50.0 |

| Umuheto | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm × 10mm) | |

| Jenerali Ibiranga | Igishushanyo | - | Uburebure bwuzuye ≤ 1/2 Wumurambararo |

| Imipira | - | Chip2 chip, Buri radiyo≤1.5mm | |

| Ubuso bw'ibyuma byanduye | atom / cm2 | ≤5E10 atom / cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Kugenzura neza | % | ≥ 96.0 (2X2 Inenge zirimo Micropipe / Ibyobo binini, Karoti, inenge ya mpandeshatu, Kugwa, Umurongo / IGSF-s, BPD) | |

| Ubuso bw'ibyuma byanduye | atom / cm2 | ≤5E10 atom / cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Amapaki | Gupakira ibisobanuro | - | cassette nyinshi-wafer cyangwa ikintu kimwe cya wafer |

Ikibazo cya SiC wafer

Q1: Ni izihe nyungu zingenzi zo gukoresha waferi ya SiC hejuru ya silikoni gakondo muri electronics?

A1:

SiC wafers itanga ibyiza byinshi byingenzi bya silikoni gakondo (Si) muri electronics yamashanyarazi, harimo:

Gukora neza: SiC ifite umurongo mugari (3.26 eV) ugereranije na silicon (1.1 eV), ituma ibikoresho bikora kuri voltage nyinshi, inshuro nyinshi, nubushyuhe. Ibi biganisha ku gutakaza ingufu nke no gukora neza muri sisitemu yo guhindura ingufu.

Ubushyuhe bwo hejuru: Ubushyuhe bwa SiC burenze kure ubwa silikoni, butuma ubushyuhe bukwirakwizwa neza mumashanyarazi menshi, bitezimbere kwizerwa no kubaho kwamashanyarazi.

Umuvuduko wo hejuru hamwe nuyobora: Ibikoresho bya SiC birashobora gukoresha voltage nini ninzego zubu, bigatuma bikenerwa nimbaraga nyinshi nkibinyabiziga byamashanyarazi, sisitemu yingufu zishobora kuvugururwa, hamwe na moteri yinganda.

Umuvuduko Wihuse: Ibikoresho bya SiC bifite ubushobozi bwihuse bwo guhinduranya, bigira uruhare mukugabanya gutakaza ingufu nubunini bwa sisitemu, bigatuma biba byiza kubikorwa byinshyi nyinshi.

Q2: Ni ubuhe buryo bukoreshwa bwa waC wafers mu nganda zitwara ibinyabiziga?

A2:

Mu nganda zitwara ibinyabiziga, wafers ya SiC ikoreshwa cyane cyane muri:

Imashanyarazi (EV) Imbaraga: Ibice bishingiye kuri SiC nkainverternaimbaraga MOSFETSkunoza imikorere n'imikorere ya powertrain yimodoka itanga ubushobozi bwo guhinduranya byihuse nubucucike bwinshi. Ibi biganisha ku burebure bwa bateri no gukora neza muri rusange.

Amashanyarazi: Ibikoresho bya SiC bifasha kunoza imikorere ya sisitemu yo kwishyuza mu ndege ituma ibihe byogushiramo byihuse hamwe n’imicungire myiza y’amashyanyarazi, ari ingenzi cyane kuri EV kugirango zishyigikire amashanyarazi menshi.

Sisitemu yo gucunga bateri (BMS): Ikoranabuhanga rya SiC ritezimbere imikorere yasisitemu yo gucunga bateri, kwemerera kugenzura neza voltage, gukoresha ingufu nyinshi, hamwe nigihe kirekire cya bateri.

Guhindura DC-DC: Wafers ya SiC ikoreshwa muriGuhindura DC-DCguhindura ingufu za DC zifite ingufu nyinshi mumashanyarazi ya DC neza cyane, ningirakamaro mubinyabiziga byamashanyarazi gucunga ingufu ziva muri bateri kugeza ibice bitandukanye mumodoka.

Ibikorwa byiza bya SiC mumashanyarazi menshi, ubushyuhe bwinshi, hamwe nubushakashatsi bukora neza bituma biba ngombwa ko inganda zitwara ibinyabiziga zijya mumashanyarazi.

6inch 4H-N ubwoko bwa SiC wafer ibisobanuro | ||

| Umutungo | Impamyabumenyi ya Zeru MPD (Z Grade) | Icyiciro cya Dummy (D Grade) |

| Icyiciro | Impamyabumenyi ya Zeru MPD (Z Grade) | Icyiciro cya Dummy (D Grade) |

| Diameter | 149.5 mm - mm 150.0 | 149.5 mm - mm 150.0 |

| Ubwoko bwa poly | 4H | 4H |

| Umubyimba | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Icyerekezo cya Wafer | Hanze ya axis: 4.0 ° yerekeza kuri <1120> ± 0.5 ° | Hanze ya axis: 4.0 ° yerekeza kuri <1120> ± 0.5 ° |

| Ubucucike bwa Micropipe | ≤ 0.2 cm² | ≤ 15 cm² |

| Kurwanya | 0.015 - 0.024 Ω · cm | 0.015 - 0.028 Ω · cm |

| Icyerekezo Cyibanze | [10-10] ± 50 ° | [10-10] ± 50 ° |

| Uburebure bwibanze | 475 mm ± 2,2 mm | 475 mm ± 2,2 mm |

| Guhezwa | Mm 3 | Mm 3 |

| LTV / TIV / Umuheto / Intambara | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Ubugome | Igipolonye Ra ≤ 1 nm | Igipolonye Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Impande Zimenetse Kumucyo mwinshi | Uburebure bwa mm 20 mm z'uburebure mm 2 mm | Uburebure bwa mm 20 mm z'uburebure mm 2 mm |

| Isahani ya Hex Kumucyo mwinshi | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 0.1% |

| Uturere twa Polytype Kumucyo mwinshi | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 3% |

| Amashusho ya Carbone | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 5% |

| Igishushanyo cya Silicon Igishushanyo Cyinshi Cyumucyo | Uburebure bwuzuye ≤ 1 wafer diameter | |

| Imipira yimpande yumucyo mwinshi | Nta numwe wemerewe ≥ 0.2 mm z'ubugari n'uburebure | 7 byemewe, mm 1 mm imwe imwe |

| Gutandukanya imirongo | <500 cm³ | <500 cm³ |

| Ubuso bwa Silicon Yanduye Kumucyo mwinshi | ||

| Gupakira | Cassette ya Multi-wafer Cyangwa Igikoresho kimwe cya Wafer | Cassette ya Multi-wafer Cyangwa Igikoresho kimwe cya Wafer |

8inch 4H-N ubwoko bwa SiC wafer ibisobanuro | ||

| Umutungo | Impamyabumenyi ya Zeru MPD (Z Grade) | Icyiciro cya Dummy (D Grade) |

| Icyiciro | Impamyabumenyi ya Zeru MPD (Z Grade) | Icyiciro cya Dummy (D Grade) |

| Diameter | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Ubwoko bwa poly | 4H | 4H |

| Umubyimba | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Icyerekezo cya Wafer | 4.0 ° yerekeza kuri <110> ± 0.5 ° | 4.0 ° yerekeza kuri <110> ± 0.5 ° |

| Ubucucike bwa Micropipe | ≤ 0.2 cm² | Cm 5 cm² |

| Kurwanya | 0.015 - 0.025 Ω · cm | 0.015 - 0.028 Ω · cm |

| Icyerekezo Cyiza | ||

| Guhezwa | Mm 3 | Mm 3 |

| LTV / TIV / Umuheto / Intambara | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Ubugome | Igipolonye Ra ≤ 1 nm | Igipolonye Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Impande Zimenetse Kumucyo mwinshi | Uburebure bwa mm 20 mm z'uburebure mm 2 mm | Uburebure bwa mm 20 mm z'uburebure mm 2 mm |

| Isahani ya Hex Kumucyo mwinshi | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 0.1% |

| Uturere twa Polytype Kumucyo mwinshi | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 3% |

| Amashusho ya Carbone | Agace kegeranye ≤ 0.05% | Agace kegeranye ≤ 5% |

| Igishushanyo cya Silicon Igishushanyo Cyinshi Cyumucyo | Uburebure bwuzuye ≤ 1 wafer diameter | |

| Imipira yimpande yumucyo mwinshi | Nta numwe wemerewe ≥ 0.2 mm z'ubugari n'uburebure | 7 byemewe, mm 1 mm imwe imwe |

| Gutandukanya imirongo | <500 cm³ | <500 cm³ |

| Ubuso bwa Silicon Yanduye Kumucyo mwinshi | ||

| Gupakira | Cassette ya Multi-wafer Cyangwa Igikoresho kimwe cya Wafer | Cassette ya Multi-wafer Cyangwa Igikoresho kimwe cya Wafer |

6Muri 4H-igice cya SiC substrate ibisobanuro | ||

| Umutungo | Impamyabumenyi ya Zeru MPD (Z Grade) | Icyiciro cya Dummy (D Grade) |

| Diameter (mm) | Mm 145 - mm 150 | Mm 145 - mm 150 |

| Ubwoko bwa poly | 4H | 4H |

| Umubyimba (um) | 500 ± 15 | 500 ± 25 |

| Icyerekezo cya Wafer | Ku murongo: ± 0.0001 ° | Ku murongo: ± 0.05 ° |

| Ubucucike bwa Micropipe | Cm 15 cm-2 | Cm 15 cm-2 |

| Kurwanya (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Icyerekezo Cyibanze | (0-10) ° ± 5.0 ° | (10-10) ° ± 5.0 ° |

| Uburebure bwibanze | Ikimenyetso | Ikimenyetso |

| Guhezwa ku mpande (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Igikombe / Intambara | ≤ 3 µm | ≤ 3 µm |

| Ubugome | Igipolonye Ra ≤ 1.5 µm | Igipolonye Ra ≤ 1.5 µm |

| Imipira yimpande yumucyo mwinshi | ≤ 20 µm | ≤ 60 µm |

| Shyushya Amasahani Kumucyo mwinshi | Igiteranyo ≤ 0.05% | Gukusanya ≤ 3% |

| Uturere twa Polytype Kumucyo mwinshi | Amashusho agaragara ya Carbone ≤ 0.05% | Gukusanya ≤ 3% |

| Igishushanyo cya Silicon Igishushanyo Cyinshi Cyumucyo | ≤ 0,05% | Umubare ≤ 4% |

| Imipira yimpande yumucyo mwinshi (Ingano) | Ntibyemewe> 02 mm Ubugari n'Uburebure | Ntibyemewe> 02 mm Ubugari n'Uburebure |

| Imfashanyo Yagutse | ≤ 500 µm | ≤ 500 µm |

| Ubuso bwa Silicon Yanduye Kumucyo mwinshi | ≤ 1 x 10 ^ 5 | ≤ 1 x 10 ^ 5 |

| Gupakira | Multi-wafer Cassette cyangwa Igikoresho kimwe cya Wafer | Multi-wafer Cassette cyangwa Igikoresho kimwe cya Wafer |

4-Inch 4H-Semi Irondora SiC Substrate Ibisobanuro

| Parameter | Impamyabumenyi ya Zeru MPD (Z Grade) | Icyiciro cya Dummy (D Grade) |

|---|---|---|

| Ibintu bifatika | ||

| Diameter | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Ubwoko bwa poly | 4H | 4H |

| Umubyimba | 500 μ m ± 15 mm | 500 μm ± 25 mm |

| Icyerekezo cya Wafer | Ku murongo: <600h> 0.5 ° | Ku murongo: <000h> 0.5 ° |

| Ibyiza by'amashanyarazi | ||

| Ubucucike bwa Micropipe (MPD) | ≤1 cm⁻² | ≤15 cm⁻² |

| Kurwanya | ≥150 Ω · cm | ≥1.5 Ω · cm |

| Ubworoherane bwa Geometrike | ||

| Icyerekezo Cyibanze | (0 × 10) ± 5.0 ° | (0 × 10) ± 5.0 ° |

| Uburebure bwibanze | 52.5 mm ± 2,2 mm | 52.5 mm ± 2,2 mm |

| Uburebure bwa kabiri | 18.0 mm ± 2,2 mm | 18.0 mm ± 2,2 mm |

| Icyerekezo cya kabiri cya Flat | 90 ° CW kuva kuri Prime igororotse ± 5.0 ° (Si reba hejuru) | 90 ° CW kuva kuri Prime igororotse ± 5.0 ° (Si reba hejuru) |

| Guhezwa | Mm 3 | Mm 3 |

| LTV / TTV / Umuheto / Intambara | ≤2.5 μ m / ≤5 μ m / ≤15 μ m / ≤30 mm | ≤10 μ m / ≤15 μ m / ≤25 μ m / ≤40 mm |

| Ubwiza bw'ubuso | ||

| Ubuso Bwuzuye (Igipolonye Ra) | ≤1 nm | ≤1 nm |

| Ubuso Bwuzuye (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Ibice byo ku nkombe (Umucyo mwinshi) | Ntabwo byemewe | Uburebure bwa mm10 mm, igikoma kimwe mm2 mm |

| Inenge ya Hexagonal | ≤0.05% agace kegeranye | ≤0.1% agace kegeranye |

| Ibice birimo Polytype | Ntabwo byemewe | ≤1% agace kegeranye |

| Amashusho ya Carbone | ≤0.05% agace kegeranye | ≤1% agace kegeranye |

| Igishushanyo cya Silicon | Ntabwo byemewe | ≤1 wafer diameter cumulative uburebure |

| Imipira | Ntanumwe wemerewe (≥0.2 mm ubugari / ubujyakuzimu) | Chip5 chip (buri ≤1 mm) |

| Ubuso bwa Silicon | Ntabwo bisobanuwe neza | Ntabwo bisobanuwe neza |

| Gupakira | ||

| Gupakira | Cassette ya Multi-Wafer cyangwa ikintu kimwe cya wafer | Cassette ya Multi-wafer cyangwa |

| 6-santimetero N-ubwoko bwa epit axial ibisobanuro | |||

| Parameter | igice | Z-MOS | |

| Andika | Conditivity / Dopant | - | N-Ubwoko / Azote |

| Buffer | Ubunini bwa Buffer | um | 1 |

| Buffer Urwego rwo Kworoherana | % | ± 20% | |

| Ihuriro rya Buffer | cm-3 | 1.00E + 18 | |

| Buffer Layeri Yibanze Kwihanganirana | % | ± 20% | |

| Igice cya 1 Epi | Epi Umubyimba | um | 11.5 |

| Epi Umubyimba Uburinganire | % | ± 4% | |

| Epi Imirongo Yoroherana ((Ubwoko- Max , Min) / Ubwoko) | % | ± 5% | |

| Epi Yibanze | cm-3 | 1E 15 ~ 1E 18 | |

| Epi Igice cyo Kworoherana | % | 6% | |

| Epi Igice cyo Kwishyira hamwe (σ / bivuze) | % | ≤5% | |

| Epi Igice cyo Kwishyira hamwe <(max-min) / (max + min> | % | ≤ 10% | |

| Epitaixal Wafer Shape | Umuheto | um | ≤ ± 20 |

| INTAMBARA | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Ibiranga rusange | Uburebure | mm | ≤30mm |

| Imipira | - | NTAWE | |

| Inenge | ≥97% Yapimwe na 2 * 2 , Inenge z'abicanyi zirimo: Inenge zirimo Micropipe / Ibyobo binini, Karoti, inyabutatu | ||

| Kwanduza ibyuma | atom / cm² | d f f ll i ≤5E10 atom / cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Amapaki | Gupakira ibisobanuro | pcs / agasanduku | cassette nyinshi-wafer cyangwa ikintu kimwe cya wafer |

| 8-santimetero N-ubwoko bwa epitaxial | |||

| Parameter | igice | Z-MOS | |

| Andika | Conditivity / Dopant | - | N-Ubwoko / Azote |

| Buffer | Ubunini bwa Buffer | um | 1 |

| Buffer Urwego rwo Kworoherana | % | ± 20% | |

| Ihuriro rya Buffer | cm-3 | 1.00E + 18 | |

| Buffer Layeri Yibanze Kwihanganirana | % | ± 20% | |

| Igice cya 1 Epi | Ikigereranyo cya Epi | um | 8 ~ 12 |

| Epi Ibice Byinshi Uburinganire (σ / bivuze) | % | ≤2.0 | |

| Epi Imirongo Yoroheye ((Ubwoko -Max , Min) / Ubwoko) | % | ± 6 | |

| Epi Layers Net Impuzandengo ya Doping | cm-3 | 8E + 15 ~ 2E + 16 | |

| Epi Imirongo Net Doping Uniformity (σ / bivuze) | % | ≤5 | |

| Epi Imirongo Net DopingTolerance ((Ubwoko -Max , | % | ± 10.0 | |

| Epitaixal Wafer Shape | Mi) / S) Intambara | um | ≤50.0 |

| Umuheto | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm × 10mm) | |

| Jenerali Ibiranga | Igishushanyo | - | Uburebure bwuzuye ≤ 1/2 Wumurambararo |

| Imipira | - | Chip2 chip, Buri radiyo≤1.5mm | |

| Ubuso bw'ibyuma byanduye | atom / cm2 | ≤5E10 atom / cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Kugenzura neza | % | ≥ 96.0 (2X2 Inenge zirimo Micropipe / Ibyobo binini, Karoti, inenge ya mpandeshatu, Kugwa, Umurongo / IGSF-s, BPD) | |

| Ubuso bw'ibyuma byanduye | atom / cm2 | ≤5E10 atom / cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg, Na, K, Ti, Ca & Mn) | |

| Amapaki | Gupakira ibisobanuro | - | cassette nyinshi-wafer cyangwa ikintu kimwe cya wafer |

Q1: Ni izihe nyungu zingenzi zo gukoresha waferi ya SiC hejuru ya silikoni gakondo muri electronics?

A1:

SiC wafers itanga ibyiza byinshi byingenzi bya silikoni gakondo (Si) muri electronics yamashanyarazi, harimo:

Gukora neza: SiC ifite umurongo mugari (3.26 eV) ugereranije na silicon (1.1 eV), ituma ibikoresho bikora kuri voltage nyinshi, inshuro nyinshi, nubushyuhe. Ibi biganisha ku gutakaza ingufu nke no gukora neza muri sisitemu yo guhindura ingufu.

Ubushyuhe bwo hejuru: Ubushyuhe bwa SiC burenze kure ubwa silikoni, butuma ubushyuhe bukwirakwizwa neza mumashanyarazi menshi, bitezimbere kwizerwa no kubaho kwamashanyarazi.

Umuvuduko wo hejuru hamwe nuyobora: Ibikoresho bya SiC birashobora gukoresha voltage nini ninzego zubu, bigatuma bikenerwa nimbaraga nyinshi nkibinyabiziga byamashanyarazi, sisitemu yingufu zishobora kuvugururwa, hamwe na moteri yinganda.

Umuvuduko Wihuse: Ibikoresho bya SiC bifite ubushobozi bwihuse bwo guhinduranya, bigira uruhare mukugabanya gutakaza ingufu nubunini bwa sisitemu, bigatuma biba byiza kubikorwa byinshyi nyinshi.

Q2: Ni ubuhe buryo bukoreshwa bwa waC wafers mu nganda zitwara ibinyabiziga?

A2:

Mu nganda zitwara ibinyabiziga, wafers ya SiC ikoreshwa cyane cyane muri:

Imashanyarazi (EV) Imbaraga: Ibice bishingiye kuri SiC nkainverternaimbaraga MOSFETSkunoza imikorere n'imikorere ya powertrain yimodoka itanga ubushobozi bwo guhinduranya byihuse nubucucike bwinshi. Ibi biganisha ku burebure bwa bateri no gukora neza muri rusange.

Amashanyarazi: Ibikoresho bya SiC bifasha kunoza imikorere ya sisitemu yo kwishyuza mu ndege ituma ibihe byogushiramo byihuse hamwe n’imicungire myiza y’amashyanyarazi, ari ingenzi cyane kuri EV kugirango zishyigikire amashanyarazi menshi.

Sisitemu yo gucunga bateri (BMS): Ikoranabuhanga rya SiC ritezimbere imikorere yasisitemu yo gucunga bateri, kwemerera kugenzura neza voltage, gukoresha ingufu nyinshi, hamwe nigihe kirekire cya bateri.

Guhindura DC-DC: Wafers ya SiC ikoreshwa muriGuhindura DC-DCguhindura ingufu za DC zifite ingufu nyinshi mumashanyarazi ya DC neza cyane, ningirakamaro mubinyabiziga byamashanyarazi gucunga ingufu ziva muri bateri kugeza ibice bitandukanye mumodoka.

Ibikorwa byiza bya SiC mumashanyarazi menshi, ubushyuhe bwinshi, hamwe nubushakashatsi bukora neza bituma biba ngombwa ko inganda zitwara ibinyabiziga zijya mumashanyarazi.